Influence of mass and installation location of workpiece on dynamic characteristics of ball screw feed system

-

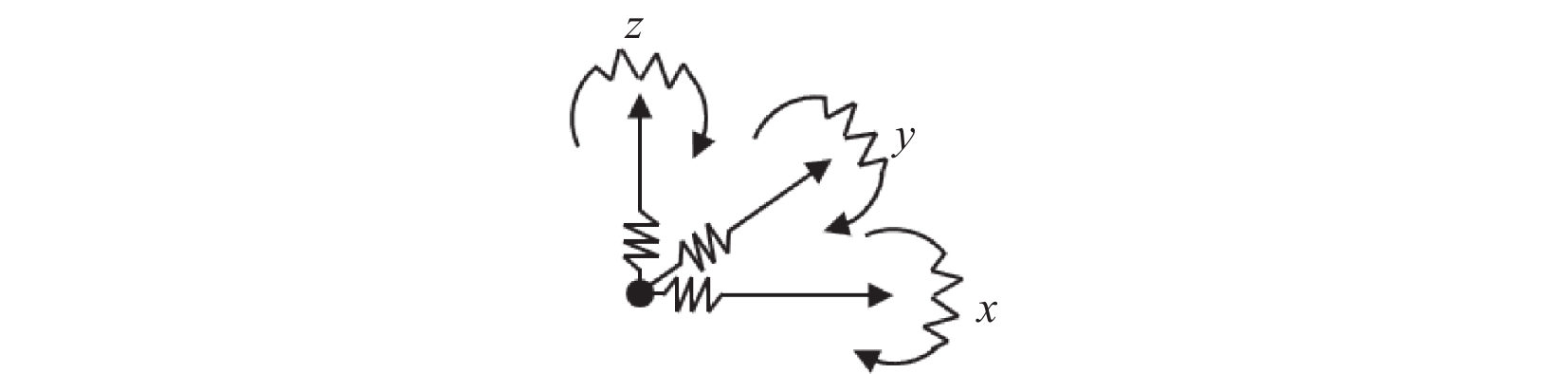

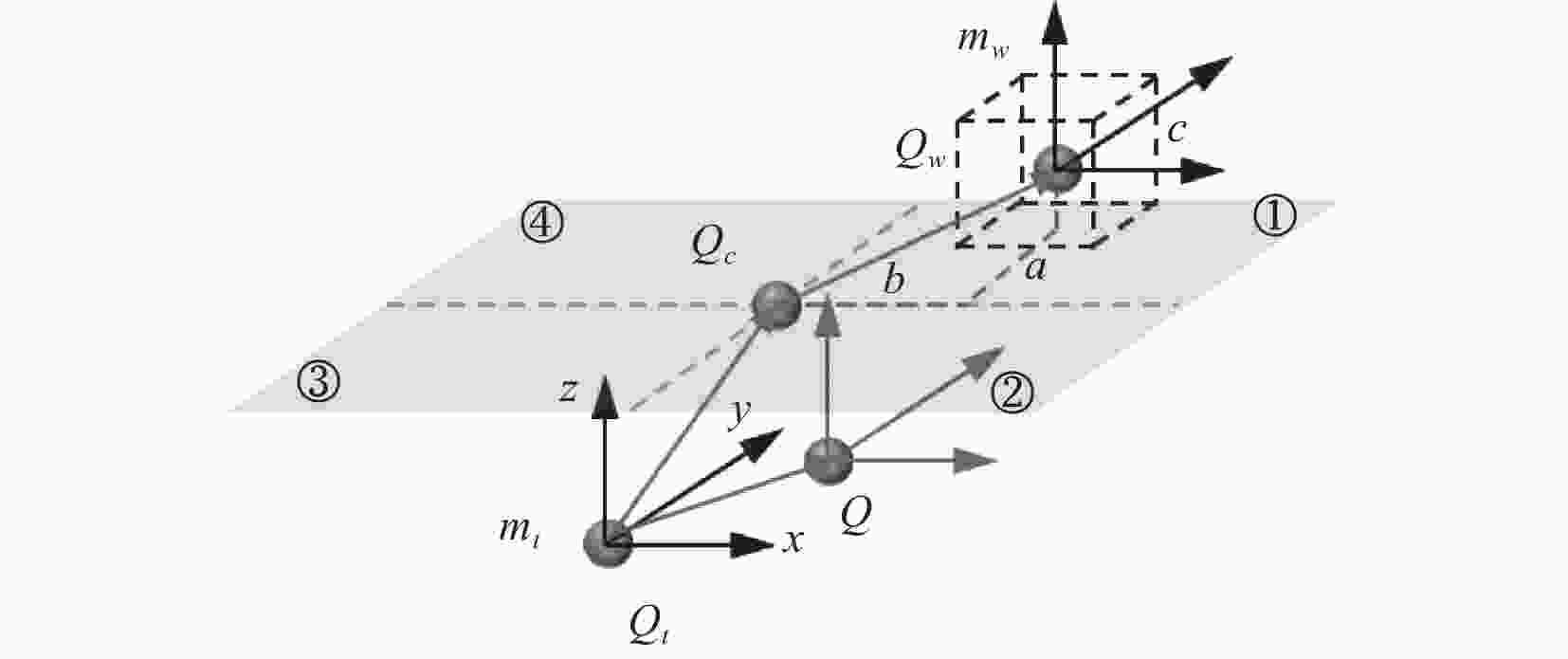

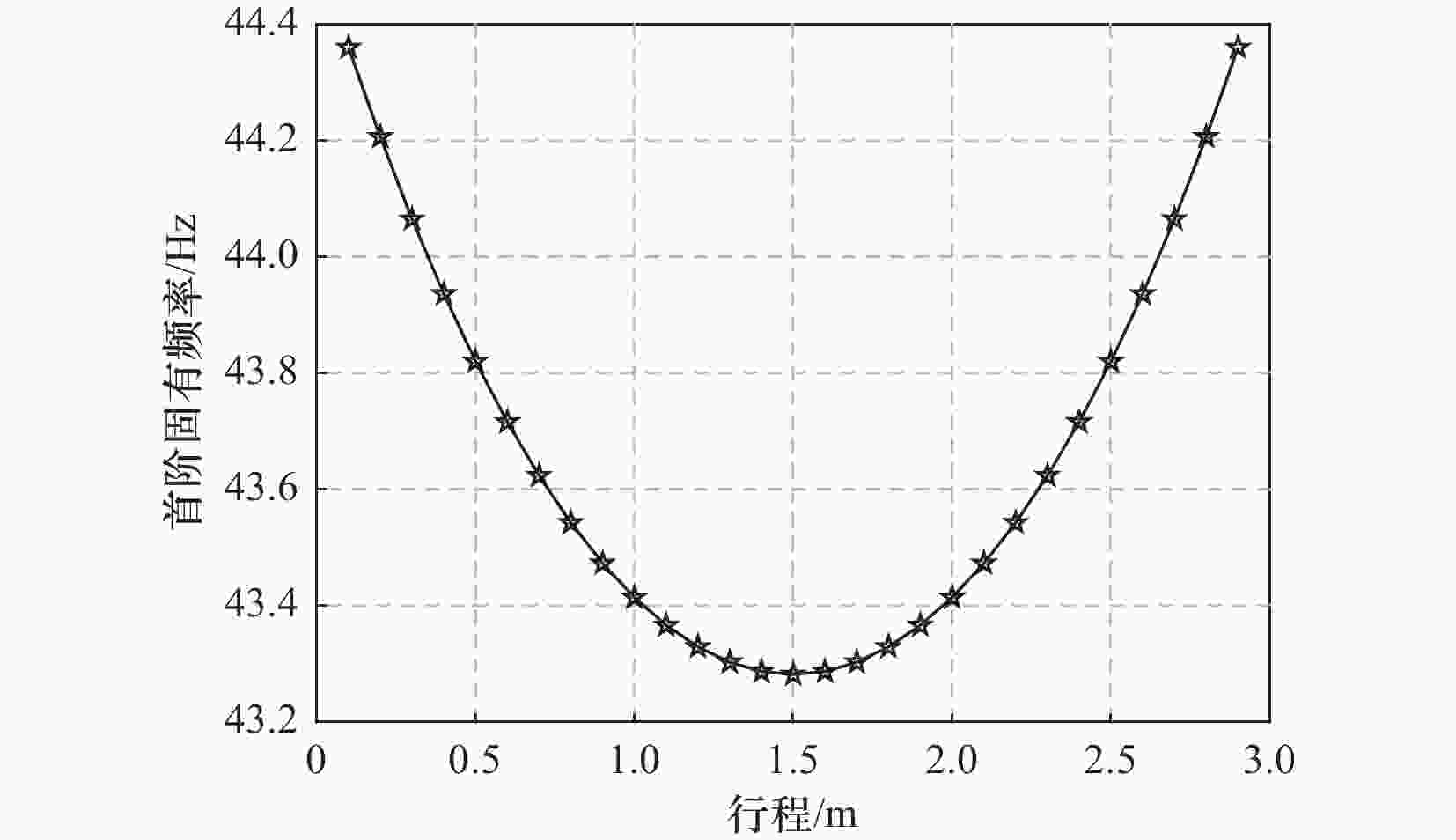

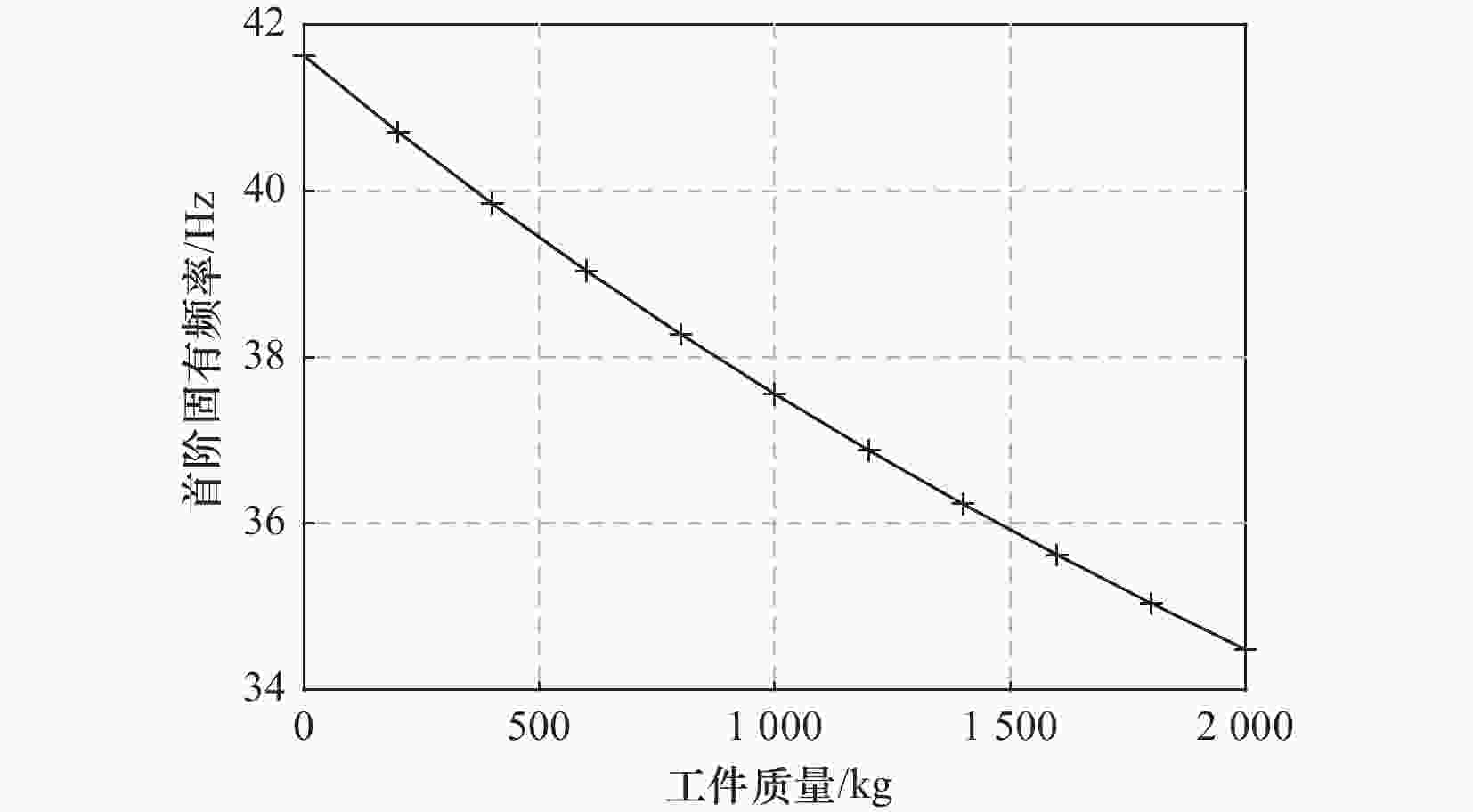

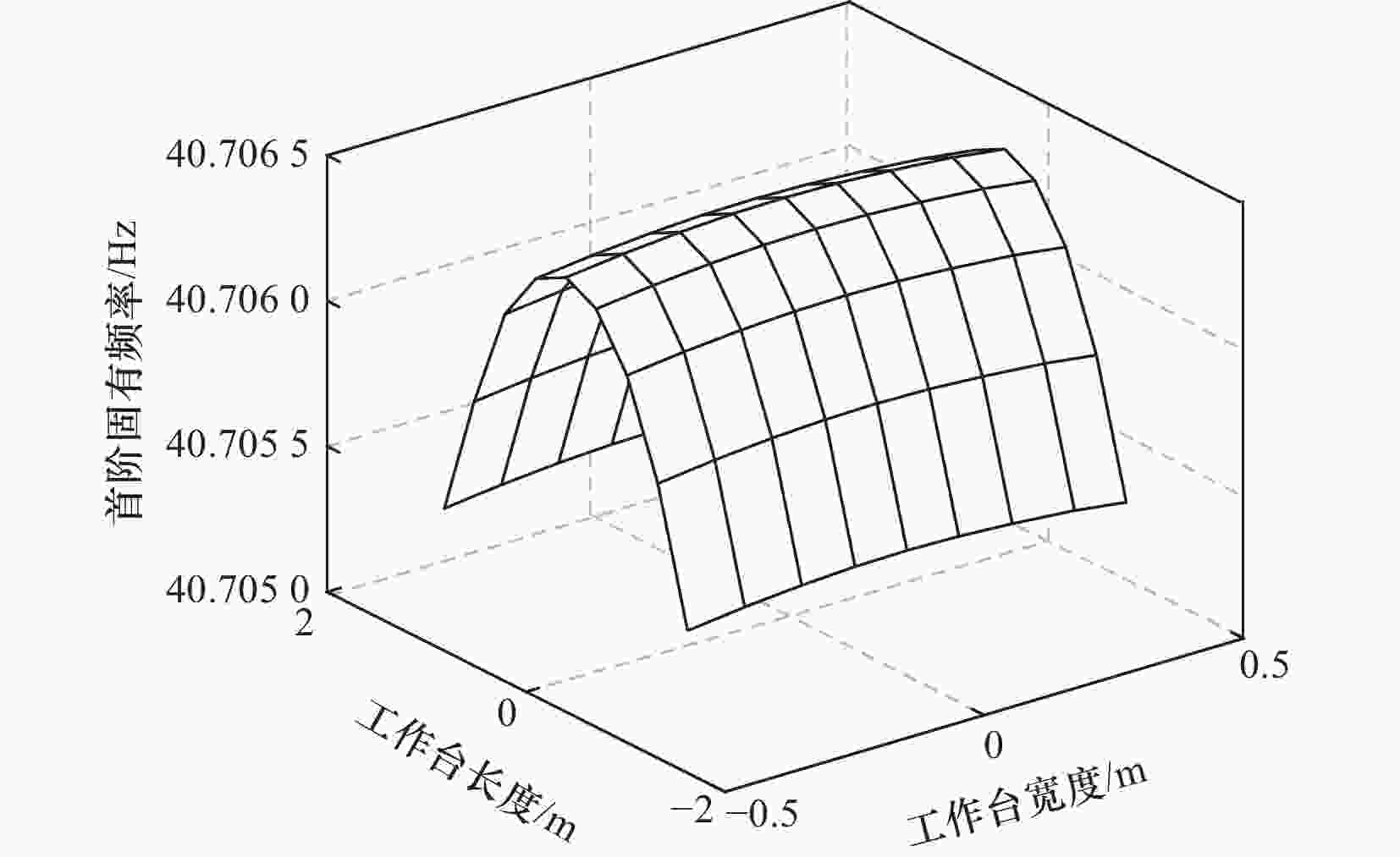

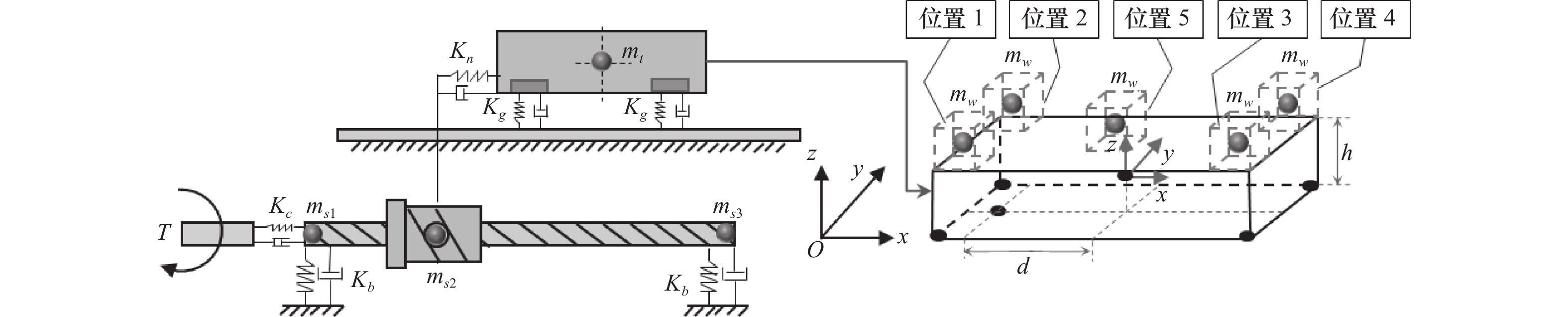

摘要: 滚珠丝杠进给系统是数控机床的关键部件,其动态特性与运动精度紧密相关,对数控机床加工精度有重要影响。滚珠丝杠进给系统的动态特性具有明显的时变特征,为探究工件质量及放置位置对滚珠丝杠进给系统动态特性的影响规律,基于集中质量法构建了滚珠丝杠进给系统动力学模型,并利用有限元方法验证了模型精确度。基于所构建的动力学模型开展了工件质量及放置位置对滚珠丝杠进给系统动态特性的影响规律分析,构建了其响应面,结果显示,随着工件质量的增加,滚珠丝杠进给系统固有频率降低;工件位置离工作台重心越近,对系统固有频率影响越小。结果可用于实际加工过程中,指导工件的在工作台面的放置位置选择。Abstract: The ball screw feed system is a key component of CNC machine tool. The motion precision of the ball screw feed system is closely related with the dynamic characteristics, and has an important influence on the machining accuracy of CNC machine tool. The dynamic characteristics of the ball screw feed system have obvious time-varying characteristics. In order to explore the influence of the mass and placement of the workpiece on the dynamic characteristics of the ball screw feed system, a dynamic model of the ball screw feed system was constructed based on the lumped mass method, and the accuracy of the model was verified by the finite element method. Based on the constructed dynamic model, the influence of the mass and placement of the workpiece on the dynamic characteristics of the ball screw feed system was analyzed, and its response surface was constructed. The results showed that the natural frequency of the ball screw feed system decreased with the increase of the quality of the workpiece. The closer the workpiece is to the center of gravity of the worktable, the less influence it has on the natural frequency of the system. The results can be used to guide the placement of the workpiece on the worktable in the actual machining process.

-

表 1 滚珠丝杠进给系统结构参数

零件 参数 值 丝杠参数 长度、根径/m 3.2、0.06491 导程、行程/m 0.016、2.8 弹性模量E/MPa 2.06×1011 工作台参数 长、宽、高/m重量 /kg 2.8、1.2、0.224431 工件参数 边长/m质量/kg 0.354200 运动副参数 轴承刚度/(N/μm、N·mm/rad) [526, 232, 232,0, 216, 216] 丝杠螺母刚度/(N/μm、N·mm/rad) [664, 286, 286, 0, 276, 276] 导轨滑块刚度/(N/μm、N·mm/rad) [0, 325, 325, 88.5, 88.5, 88.5] 表 2 模型首阶固有频率计算结果对比

Hz 模型 位置1 位置2 位置3 位置4 位置5 无工件 数值模型 40.705 40.705 40.705 40.705 40.706 43.33 有限元模型 37.128 37.128 37.383 37.383 37.286 41.655 误差/(%) 9.63 9.63 8.89 8.89 9.17 4.02 -

[1] 庾辉, 李梦奇, 李冬英, 等. 数控机床定位精度研究进展[J]. 机械设计与研究, 2015, 31(6): 101-104,108. [2] 吕盾, 李润泽, 刘辉, 等. 数控机床高速高加速进给下的跟随误差控制策略[J]. 西安交通大学学报, 2018, 52(12): 25-31. [3] 苏芳, 王晨升, 贾进生. 重型直线进给系统动态特性研究[J]. 制造技术与机床, 2019(7): 48-51,55. [4] Zhang H J, Hui L, Chao D, et al. Dynamics analysis of a slender ball-screw feed system considering the changes of the worktable position[J]. Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science, 2019, 233(8): 2685-2695. doi: 10.1177/0954406218799781 [5] 满兵, 郭永环, 范希营, 等. 机床滚珠丝杠进给系统热误差研究现状与发展趋势[J]. 机床与液压, 2021, 49(15): 174-179. [6] 陈勇将, 汤文成, 郭魂, 等. 基于虚拟材料的滚珠丝杠进给系统建模及其时变特性研究[J]. 制造技术与机床, 2021(1): 43-47. [7] 苏芳, 王晨升, 郭刚, 等. 计及惯量比变化的直线进给系统动态误差分析[J]. 机械科学与技术, 2020, 39(12): 1882-1888. [8] Zhang T T, Zhang D S, Zhang Z, et al. Investigation on the load-inertia ratio of machine tools working in high speed and high acceleration processes[J]. Mechanism and Machine Theory, 2021, 155: 104093. doi: 10.1016/j.mechmachtheory.2020.104093 [9] Sato R , Shirase K , Hayashi A. Energy consumption of feed drive systems based on workpiece setting position in five-axis machining center[J]. Journal of Manufacturing Science and Engineering, 2017, 140(2): 1087-1357. -

下载:

下载: