Present situation and analysis of micro drilling of nickel base alloy

-

摘要: 镍基合金因其优异的物理性能被广泛应用于航空涡轮发动机中,而航空涡轮发动机涉及到许多精密零件需要用微钻进行加工,钻削镍基合金时材料加工硬化现象严重,致使加工难度增加,刀具磨损严重,影响钻孔质量。分析了镍基合金微小孔钻削面临的难题,从切屑形成机制、钻削力与扭矩、钻削热和钻削温度等方面对微钻削机理进行了总结和讨论,分析了钻头的磨损形式、影响因素和磨损机制,探讨了影响毛刺、白层和圆度等孔加工质量的因素,从刀具几何形状、刀具材料和辅助钻削方法等方面提出了一些提高孔加工质量的措施。Abstract: Nickel base alloy is widely used in aviation turbine engine because of its excellent physical properties. Many precision parts of aviation turbine engine need to be processed with micro drill. When drilling nickel base alloy, the material work hardening phenomenon is serious, resulting in increased machining difficulty, serious tool wear and affecting the drilling quality. This paper analyzes the difficulties faced by nickel base alloy micro hole drilling, summarizes and discusses the micro drilling mechanism from the aspects of chip formation mechanism, drilling force and torque, drilling heat and drilling temperature, analyzes the wear form, influencing factors and wear mechanism of the bit, and discusses the factors affecting the hole processing quality such as burr, white layer, roundness, from the aspects of tool geometry, tool material some measures to improve the hole processing quality are put forward from the aspects of auxiliary drilling methods.

-

Key words:

- micro drilling /

- nickel-based alloy /

- existing problems /

- wear of micro drill /

- processing quality

-

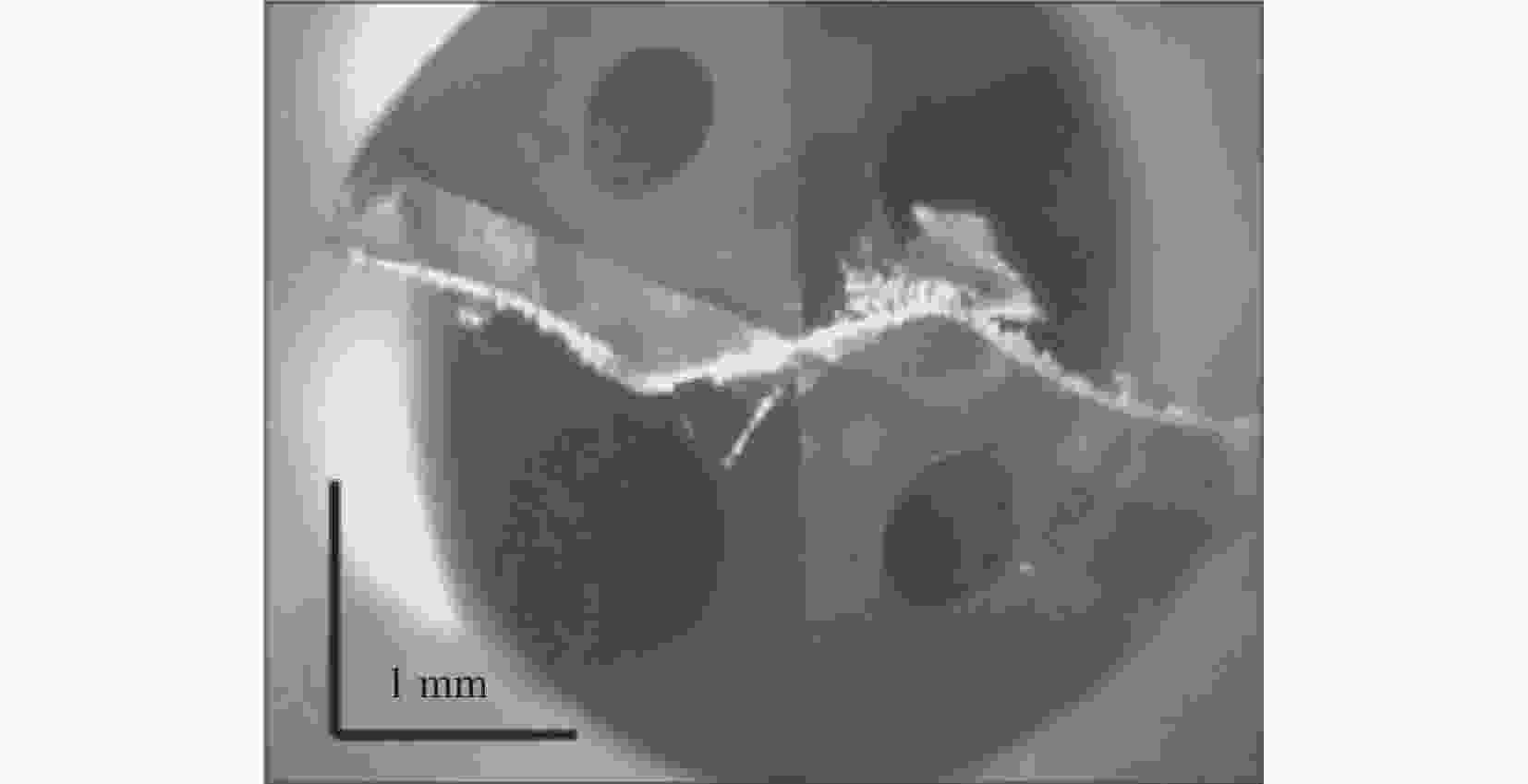

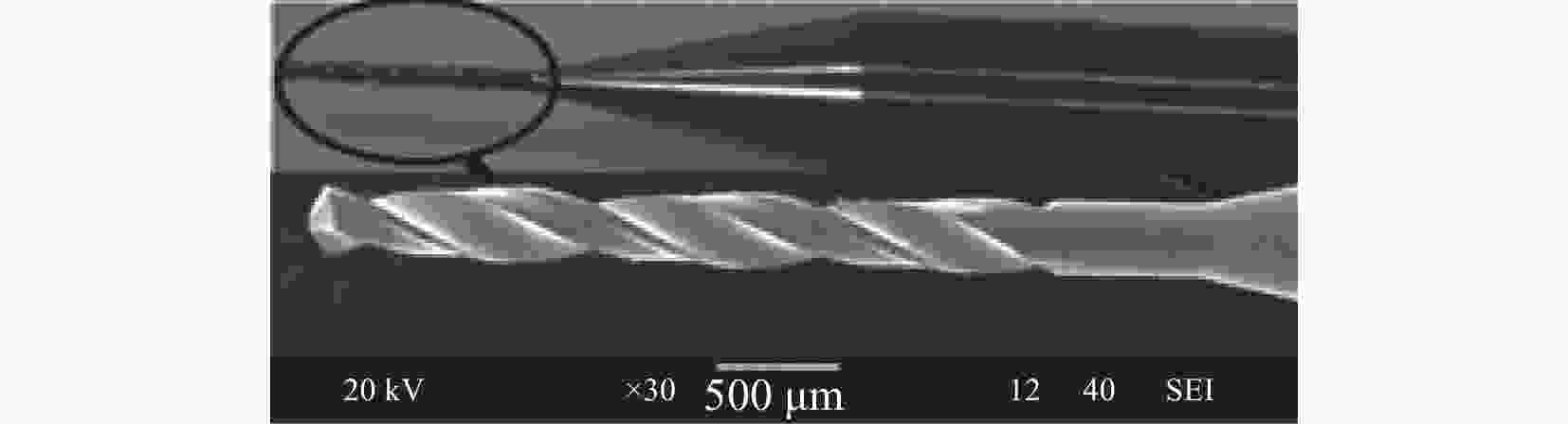

图 1 前刀面磨损[15]

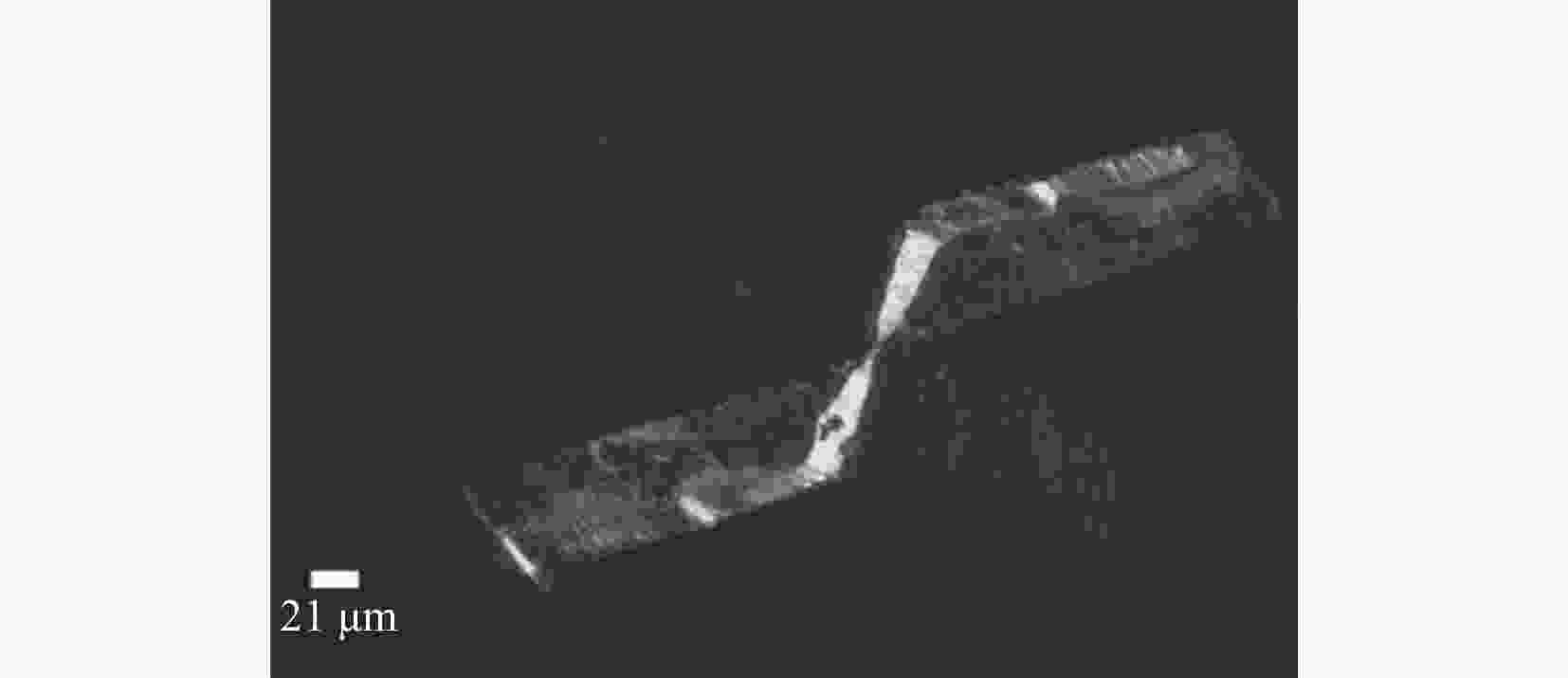

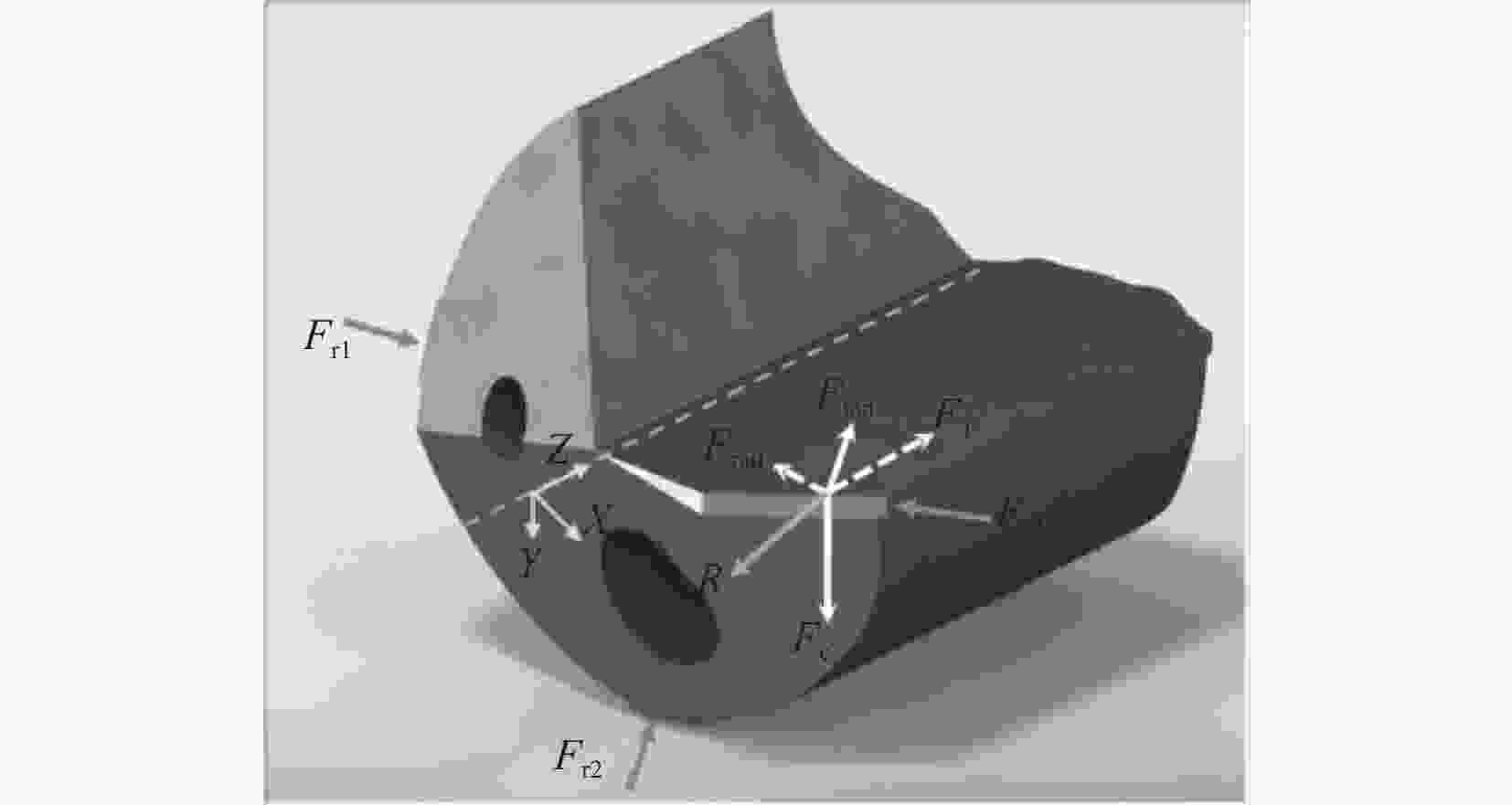

图 2 切削刃与横刃磨损[16]

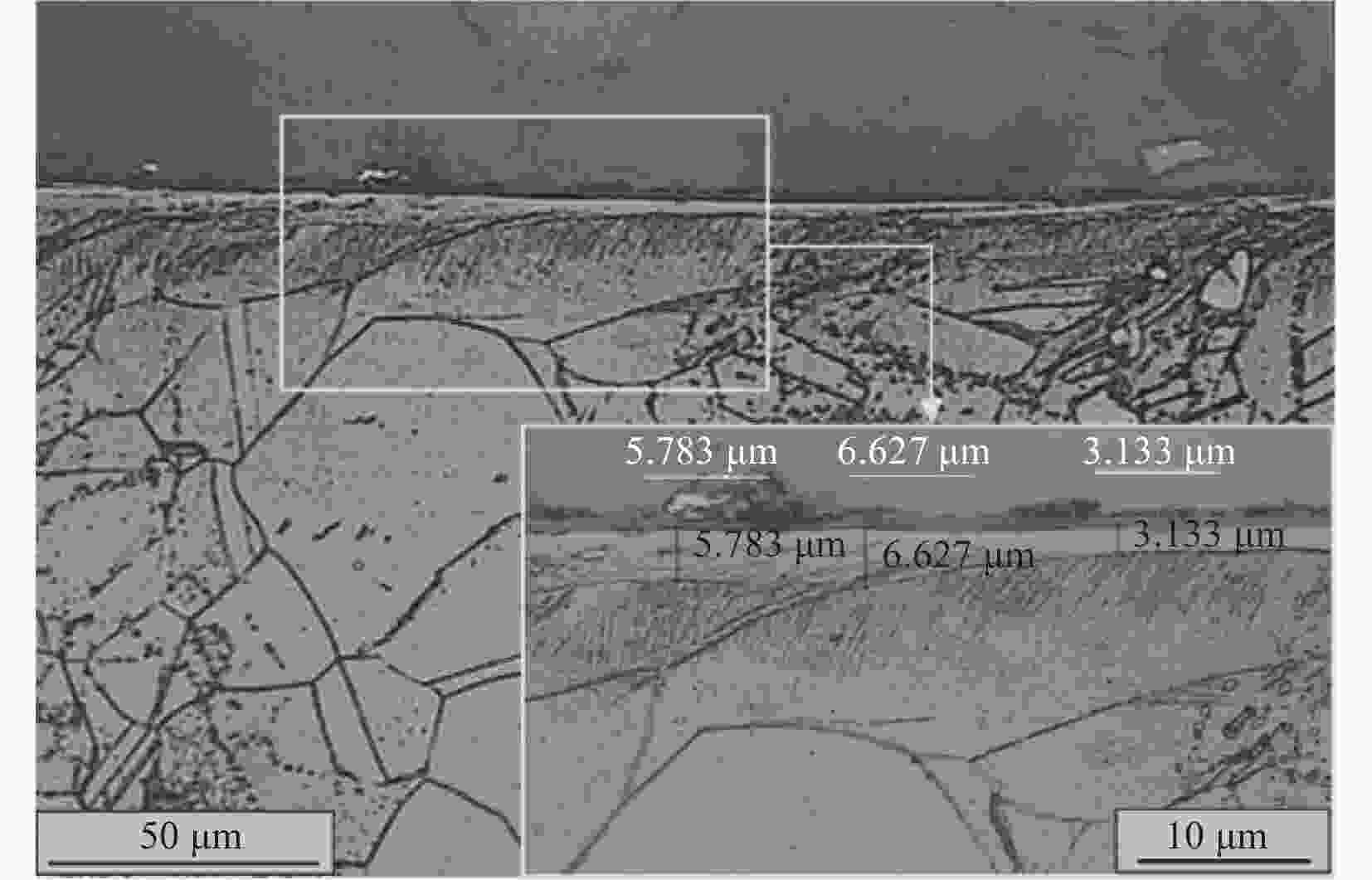

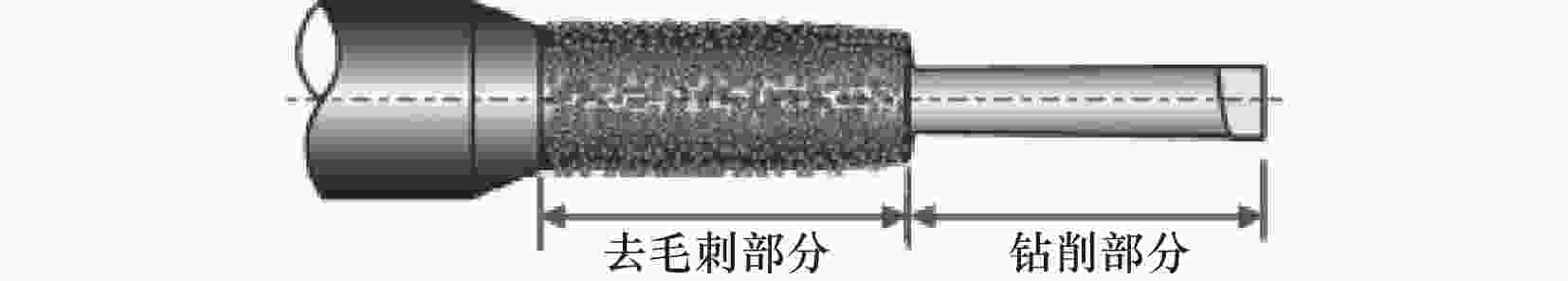

图 3 后刀面磨损[17]

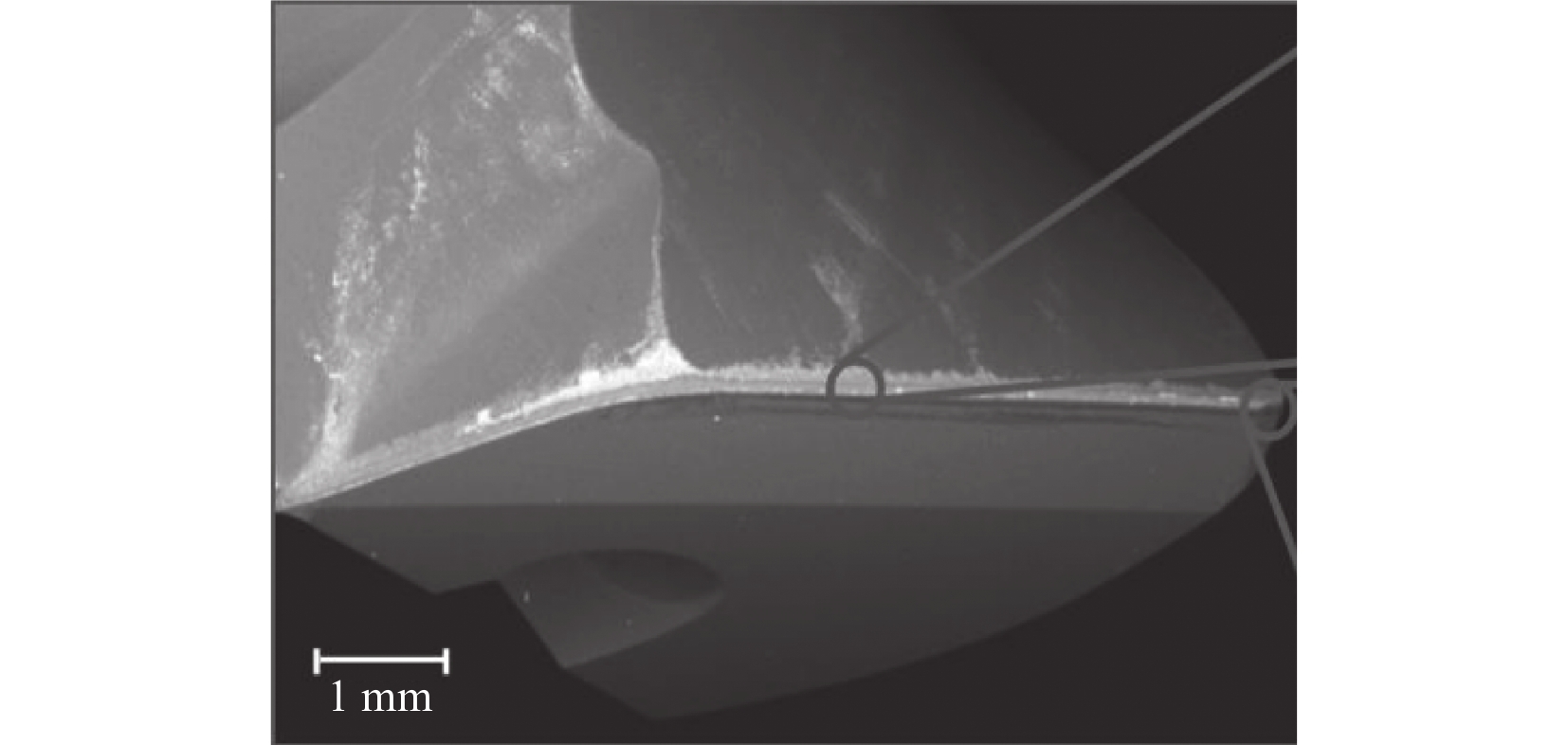

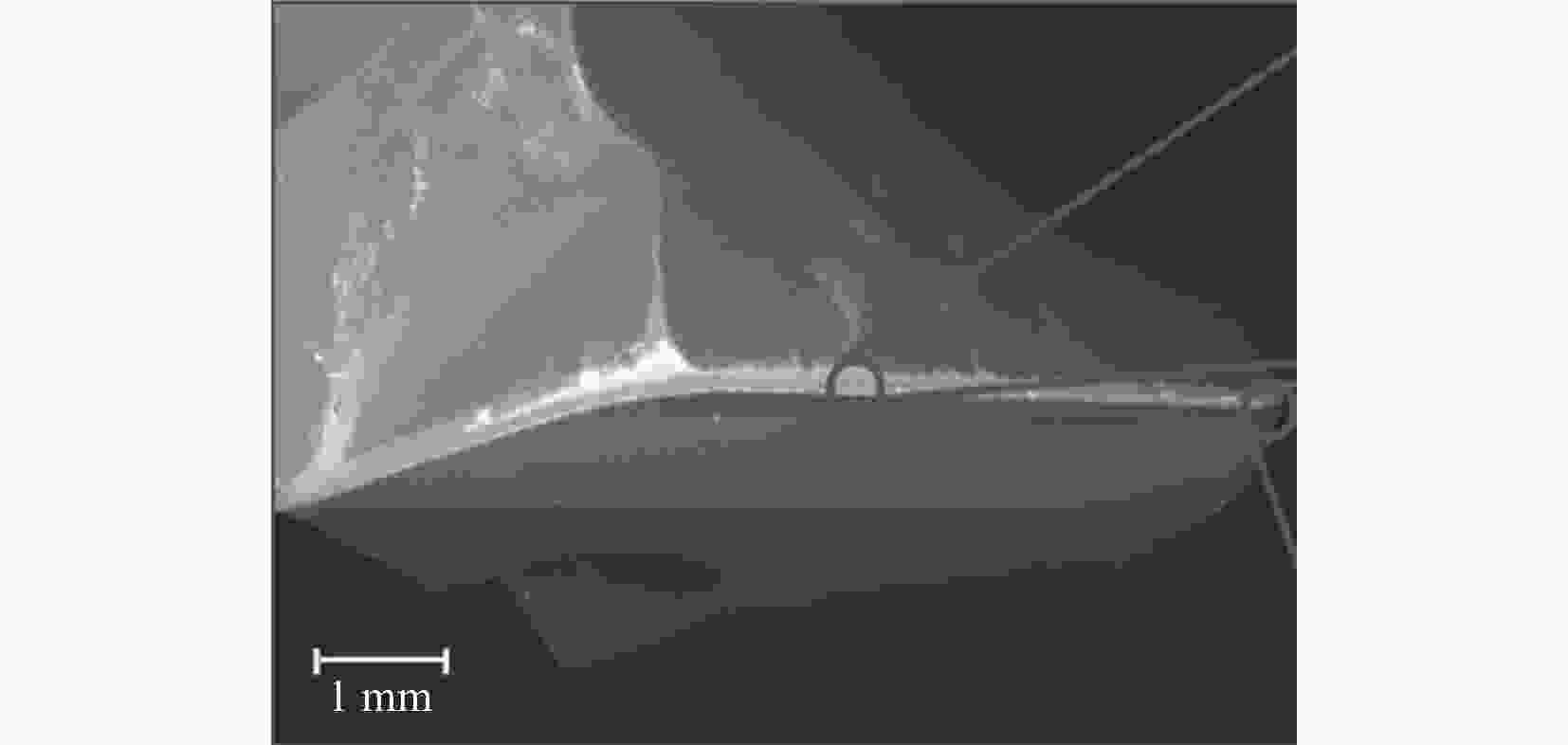

图 4 白层[24]

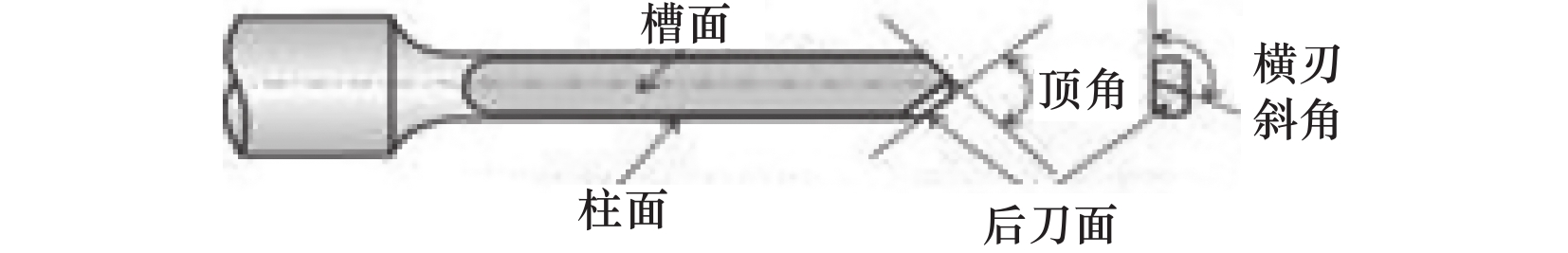

-

[1] Yonezawa T. Nickel alloys: properties and characteristics [M]. Comprehensive Nuclear Materials, 2012: 233-266. [2] 姬芳芳. 高速切削 GH4169 切削区材料塑性行为研究[D]. 长春: 长春工业大学, 2018. [3] Motorcu A R, Kuş A, Durgun I. The evaluateon of the effects of control factors on surface roughness in the drilling of waspaloy superalloy[J]. Measurement, 2014, 58: 394-408. doi: 10.1016/j.measurement.2014.09.012 [4] 高利. 基于涡轮发动机热端部件的高温合金材料钻削仿真研究[D]. 北京: 北方工业大学, 2021. [5] 曾维敏. 钻削过程切屑受力建模及有限元仿真研究[D]. 湘潭: 湘潭大学, 2015. [6] Sahoo A K, Jeet S, Bagal D K, et al. Parametric optimization of CNC-drilling of Inconel 718 with cryogenically treated drill-bit using Taguchi-Whale optimization algorithm[J]. Materials Today:Proceedings, 2022, 50: 1591-1598. doi: 10.1016/j.matpr.2021.09.121 [7] Cuesta M, Aristimuño P, Garay A, et al. Heat transferred to the workpiece based on temperature measurements by IR technique in dry and lubricated drilling of Inconel 718[J]. Applied Thermal Engineering, 2016, 104: 309-318. doi: 10.1016/j.applthermaleng.2016.05.040 [8] Liu J Y, Li A H, Zhang J C, et al. Performance of high-speed steel drills in wet drilling Inconel 718 superalloy[J]. Experimental Techniques, 2022: 1-12. [9] Han C, Luo M, Zhang D H, et al. Mechanistic modelling of worn drill cutting forces with drill wear effect coefficients[J]. Procedia CIRP, 2019, 82: 2-7. doi: 10.1016/j.procir.2019.04.332 [10] Xue C, Chen W Y. The performances of different coated carbide drills when drilling a cast nickel-based alloy[C].Advanced Materials Research. Trans Tech Publications Ltd. , 2012, 497: 41-45. [11] Wolf T, Iovkov I, Biermann D. Influence of a discontinuous process strategy on microstructure and micro-hardness in drilling inconel 718[J]. Journal of Manufacturing and Materials Processing, 2021, 5(2): 43. doi: 10.3390/jmmp5020043 [12] Venkatesan T, Jerald J, Pilligrin J C, et al. Experimental investigation on micro drilling of Inconel 718 super alloy[J]. International Journal of Machining and Machinability of Materials, 2018, 20(1): 48-63. doi: 10.1504/IJMMM.2018.089470 [13] 王辉. 镍基粉末冶金高温合金钻削仿真与试验研究[D]. 济南: 济南大学, 2016. [14] Nagaraj M, Kumar A, Ezilarasan C, et al. Finite element modeling in drilling of Nimonic C-263 alloy using deform-3D[J]. Computer Modeling in Engineering & Sciences, 2019, 118(3): 679-692. [15] Biermann D, Bücker M, Tiffe M, et al. Experimental investigations for a simulative optimization of the cutting edge design of twist drills used in the machining of Inconel 718[J]. Procedia Manufacturing, 2017, 14: 8-16. doi: 10.1016/j.promfg.2017.11.002 [16] Jiménez A, Arizmendi M, Sánchez J M. Extraction of tool wear indicators in peck-drilling of Inconel 718[J]. The International Journal of Advanced Manufacturing Technology, 2021, 114(9-10): 2711-2720. doi: 10.1007/s00170-021-07058-7 [17] Azim S, Gangopadhyay S, Mahapatra S S, et al. Role of PVD coating on wear and surface integrity during environment-friendly micro-drilling of Ni-based superalloy[J]. Journal of Cleaner Production, 2020, 272: 122741. doi: 10.1016/j.jclepro.2020.122741 [18] Barros P C, Barbosa G F, Ventura C E H, et al. Tool wear analysis on drilling process of Inconel 718 superalloy [R]. SAE Technical Paper, 2020. [19] Imran M, Mativenga P T, Withers P J. Assessment of machining performance using the wear map approach in micro-drilling[J]. The International Journal of Advanced Manufacturing Technology, 2012, 59(1): 119-126. [20] Imran M, Mativenga P T, Kannan S. Ealuation of the effects of tool geometry on tool wear and surface integrity in the micro drilling process for Inconel 718 alloy[J]. International Journal of Machining and Machinability of Materials, 2012, 11(3): 244-62. doi: 10.1504/IJMMM.2012.046886 [21] Wang Q, Zhang D H, Tang K, et al. A mechanics based prediction model for tool wear and power consumption in drilling operations and its applications[J]. Journal of Cleaner Production, 2019, 234: 171-184. doi: 10.1016/j.jclepro.2019.06.148 [22] Soo S L, Hood R, Aspinwall D K, et al. Machinability and surface integrity of RR1000 nickel based superalloy[J]. CIRP annals, 2011, 60(1): 89-92. doi: 10.1016/j.cirp.2011.03.094 [23] Qiao Y, Guo P Q, Chen H T, et al. Investigation of machined surface properties and gool wear for drilling of nickel-based superalloy FGH97[C]. IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2019, 562(1): 012142. [24] Lotfi M, Farid A A, Akbari J, et al. Evaluation of surface integrity when drilling Inconel 718 through experimental measurement and finite element analysis[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(7): 4237-4248. [25] Herbert C, Axinte D, Hardy M, et al. Investigation into the characteristics of white layers produced in a nickel-based superalloy from drilling operations[J]. Machining Science and Technology, 2012, 16(1): 40-52. doi: 10.1080/10910344.2012.648520 [26] Nie G C, Zhang X M, Zhang D, et al. An experimental study of the white layer formation during cryogenic assisted hard machining of AISI 52100 steel[J]. Procedia Cirp, 2018, 77: 223-226. doi: 10.1016/j.procir.2018.09.001 [27] Du J, Liu Z Q, Lv S. Deformation-phase transformation coupling mechanism of white layer formation in high speed machining of FGH95 Ni-based superalloy[J]. Applied Surface Science, 2014, 292: 197-203. doi: 10.1016/j.apsusc.2013.11.111 [28] 杜劲, 刘战强. 镍基粉末高温合金切削加工表面白层研究[J]. 稀有金属材料与工程, 2012, 41(S2): 698-702. [29] Imran M, Mativenga P T, Gholinia A, et al. Evaluation of surface integrity in micro drilling process for nickel-based superalloy[J]. The International Journal of Advanced Manufacturing Technology, 2011, 55(5): 465-476. [30] Azim S, Gangopadhyay S, Mahapatra S S, et al. Study of cutting forces and surface integrity in micro drilling of a Ni-based superalloy[J]. Journal of Manufacturing Processes, 2019, 45: 368-378. doi: 10.1016/j.jmapro.2019.07.016 [31] Prashanth P, Hiremath S S. Machinability study and charcaterisation of holes machined using mechanical micromachining technique-micro drilling[J]. Adv. Mater. Technol., 2019, 5(2): 226-241. [32] Swain N, Kumar P, Srinivas G, et al. Mechanical micro-drilling of nimonic 80A superalloy using uncoated and TiAlN-coated micro-drills[J]. Materials and Manufacturing Processes, 2017, 32(13): 1537-1546. doi: 10.1080/10426914.2017.1279293 [33] Venkatesan K, Nagendra K U, Anudeep C M, et al. Experimental investigation and parametric optimization on hole quality assessment during micro-drilling of Inconel 625 superalloy[J]. Arabian Journal for Science and Engineering, 2021, 46(3): 2283-2309. doi: 10.1007/s13369-020-04992-8 [34] Baghlani V, Mehbudi P, Akbari J, et al. Ultrasonic assisted deep drilling of Inconel 738LC superalloy[J]. Procedia CIRP, 2013, 6: 571-576. doi: 10.1016/j.procir.2013.03.096 [35] Singh M, Dhiman S, Singh H, et al. Assessment of positional error and hole quality during vibration-based drilling of aerospace alloy[J]. Journal of Mechanical Science and Technology, 2021, 35(12): 5621-5630. doi: 10.1007/s12206-021-1133-8 [36] Khanna N, Agrawal C, Gupta M K, et al. Tool wear and hole quality evaluation in cryogenic drilling of inconel 718 superalloy[J]. Tribology International, 2020, 143: 106084. doi: 10.1016/j.triboint.2019.106084 [37] Rosnan R, Murad M N, Azmi A I, et al. Effects of minimal quantity lubricants reinforced with nano-particles on the performance of carbide drills for drilling nickel-titanium alloys[J]. Tribology International, 2019, 136: 58-66. doi: 10.1016/j.triboint.2019.03.029 -

下载:

下载: