Selective laser melting quality prediction based on adaptive GDSA-BPNN

-

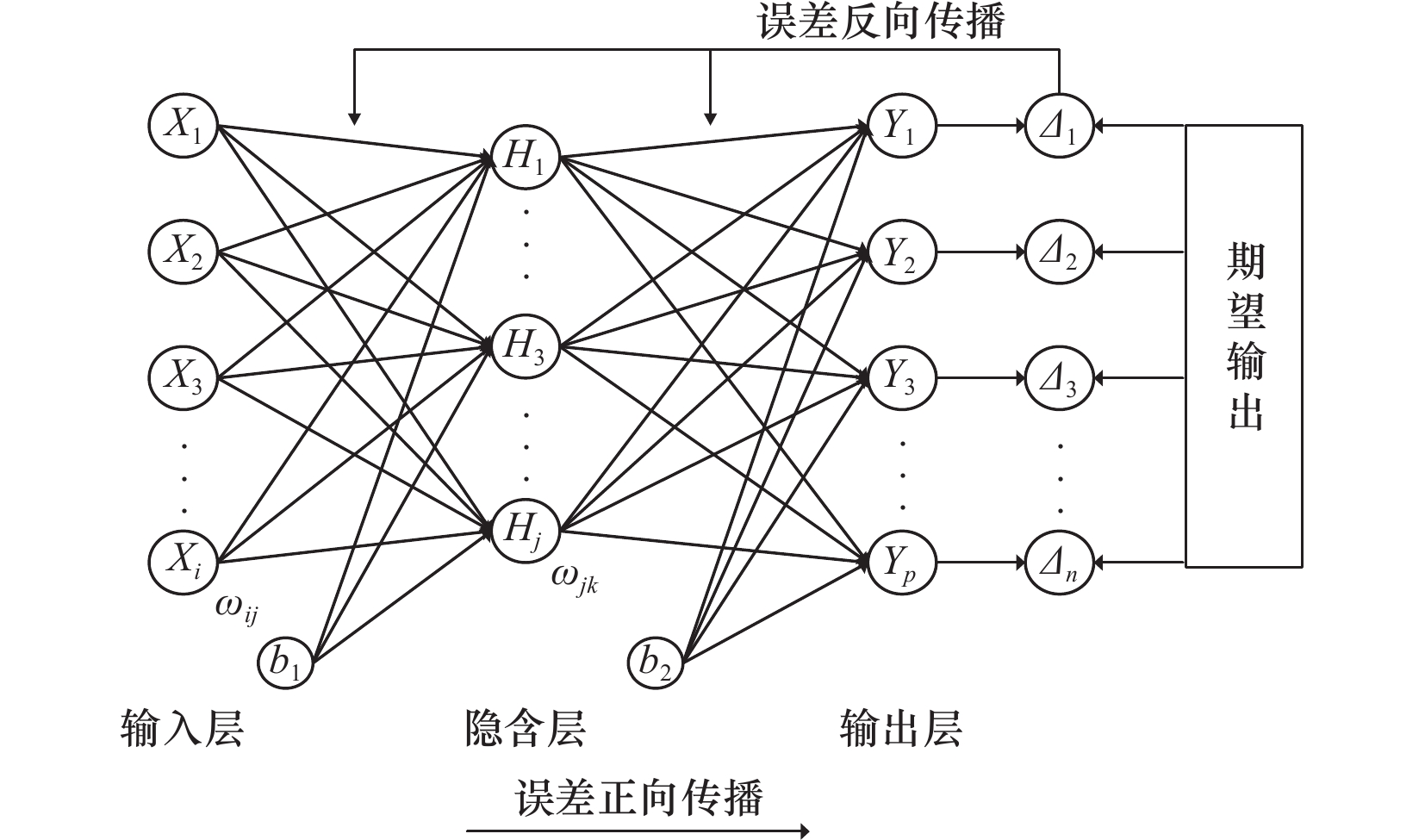

摘要: 针对增材制造选区激光熔化(selective laser melting,SLM)零件的质量缺陷问题,提出一种基于自适应策略的多输入多输出反向传播神经网络(back propagation neural network,BPNN)模型预测SLM产品质量,解决传统方法不能自适应地调整超参数来适应不同搜索阶段的问题。首先确定SLM成型的重要工艺参数和质量指标,选择Huber函数作为BP模型的损失函数,构建含有结构风险最小化策略目标函数的BP模型;其次,建立基于自适应梯度下降搜索算法(gradient descent search algorithm, GDSA)与BPNN相结合的预测模型(GDSA-BPNN),选择3种不同学习率的策略放入自适应策略库,采用一种自适应机制优化BP模型的超参数;最后,将文章所提出的GDSA-BPNN模型与其他4种模型的预测结果进行对比,结果表明基于GDSA-BPNN模型的SLM零件质量预测方法具有良好的预测效果和较高的预测精度。Abstract: To solve the quality defect problem of selected laser melting(SLM) parts in additive manufacturing, a new adaptive multi-input and multi-output Back Propagation Neural Network(BPNN) was proposed to predict SLM product quality and solve the problem that the traditional method can not adapt the hyperparameter to different search stages. Firstly, the important process parameters and quality indexes of SLM molding were determined, Huber function was selected as the loss function of BP model, and BP model containing the objective function of structural risk minimization strategy was constructed. Secondly, a prediction model (GDSA-BPNN) based on the combination of the Gradient Descent Search Algorithm (GDSA) and BPNN was established. Three strategies with different learningrates were selected and put intothe adaptivestrategy library,and an adaptive mechanism was used to optimize the hyperparameters of BP model. Finally, the prediction results of GDSA-BPNNmodelwere compared with those of other four models, and the results show that the prediction accuracy of SLM parts quality prediction method based on GDSA-BPNN model has good prediction effect and high prediction accuracy.

-

Key words:

- SLM parts /

- quality prediction /

- BPNN model /

- huber function /

- adaptive GDSA algorithm

-

表 1 SLM处理AISil10Mg样品的工艺参数和质量性能样本

输入参数 输出参数 激光功率/W 扫描速度/(mm/s) 重叠率/(%) 舱口距离/mm 相对密度 硬度/HBV 抗拉强度/MPa 孔隙率/(%) 320 600 0.25 102.84 0.973 9 119 455 2.61 320 600 0.35 88.7 0.980 2 130.8 433.33 1.98 320 750 0.25 93.1 0.977 4 124.4 448.33 2.26 360 600 0.25 111 0.968 8 127.2 431.67 3.12 360 600 0.3 103.6 0.979 135.2 436.67 2.1 360 600 0.35 96.2 0.972 5 116.4 441.67 2.75 360 750 0.25 98 0.973 2 129.8 430 2.68 360 750 0.3 91.4 0.981 7 123.2 441.67 1.83 360 900 0.25 88.9 0.973 6 119 420 2.64 360 900 0.3 83 0.979 9 127.2 431.67 2.01 400 600 0.25 116.4 0.955 9 118.6 420 4.41 400 600 0.35 100.9 0.981 2 139.2 438.33 1.88 400 750 0.25 104.7 0.972 2 124.8 430 2.78 400 750 0.3 97.7 0.976 3 127.4 431.67 2.37 400 900 0.25 94.1 0.979 5 125.4 352.2 2.05 400 900 0.3 87.8 0.965 1 113.2 383.11 3.49 400 900 0.35 81.5 0.975 8 118.4 408.18 2.42 320 750 0.35 80.7 0.977 7 127.8 445 2.23 320 900 0.25 81.8 0.981 7 127.6 443.33 1.83 320 900 0.3 76.3 0.984 7 127.8 446.67 2.16 360 750 0.35 84.9 0.973 4 128.8 445 2.66 400 600 0.3 108.6 0.979 1 131 445 2.09 320 600 0.3 95.5 0.980 1 123.2 450 1.99 320 750 0.3 86.9 0.973 7 123.2 443.33 2.63 320 900 0.35 70.9 0.981 3 122.6 450 1.97 360 900 0.35 77.1 0.979 5 122 446.67 2.05 400 750 0.35 90.7 0.969 4 120.8 443.03 3.06 表 2 不同SLM预测模型下处理AISil10Mg样品的训练误差、验证误差和测试误差

预测模型 训练误差 验证误差 测试误差 P-BP1 0.027 99 0.029 37 0.128 2 P-BP2 0.041 31 0.063 79 0.066 8 P-BP3 0.041 8 0.100 2 0.126 BP 0.064 41 0.148 3 0.147 2 GDSA-BP 0.021 43 0.026 55 0.065 -

[1] Gibson I, Rosen D W, Stucker B, et al. Additive manufacturing technologies[M]. Switzerland: Springer, 2021: 13-17. [2] Sabuj M D. Selective laser melting part quality prediction and energy consumption optimization[D]. Manitoba: The University of Manitoba of Doctoral Dissertation, 2022. [3] Shipley H,McDonnell D,Culleton M,et al. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V:A review[J]. International Journal of Machine Tools and Manufacture,2018,128:1-20. doi: 10.1016/j.ijmachtools.2018.01.003 [4] Li Z,Kucukkoc I,Zhang D Z,et al. Optimising the process parameters of selective laser melting for the fabrication of Ti6Al4V alloy[J]. Rapid Prototyping Journal,2018,24(1):150-159. doi: 10.1108/RPJ-03-2016-0045 [5] 宋剑锋,宋有年,王文武,等. 金属粉末选区激光熔化成形表面粗糙度预测及控制方法研究[J]. 中国激光,2022,49(2):81-94. [6] Cambria E,White B. Jumping NLP curves: A review of natural language processing research[J]. IEEE Computational Intelligence Magazine,2014,9(2):48-57. doi: 10.1109/MCI.2014.2307227 [7] 韩顺杰,单新超,于爱君,等. 基于改进粒子群算法的工业机器人轨迹规划[J]. 制造技术与机床,2021(4):9-14. doi: 10.19287/j.cnki.1005-2402.2021.04.001 [8] Wilson S W. The genetic algorithm and simulated evolution [M]. Routledge: Artificial life, 2019: 157-166. [9] Gudise V G, Venayagamoorthy G K. Comparison of particle swarm optimization and backpropagation as training algorithms for neural networks[C]. Proceedings of the 2003 IEEE Swarm Intelligence Symposium. SIS'03 (Cat. No. 03EX706). IEEE, 2003: 110-117. [10] Mirjalili S A,Hashim S Z M,Sardroudi H M. Training feedforward neural networks using hybrid particle swarm optimization and gravitational search algorithm[J]. Applied Mathematics and Computation,2012,218(22):11125-11137. doi: 10.1016/j.amc.2012.04.069 [11] Rumelhart D E,Hinton G E,Williams R J. Learning representations by back-propagating errors[J]. Nature,1986,323:533-536. doi: 10.1038/323533a0 [12] Xue Y,Wang Y,Liang J. A self-adaptive gradient descent search algorithm for fully-connected neural networks[J]. Neurocomputing,2022,478(12):70-80. [13] Fogel D B. An introduction to simulated evolutionary optimization[J]. IEEE Transactions on Neural Networks,1994,5(1):3-14. doi: 10.1109/72.265956 [14] Peng T,Lv J,Majeed A,et al. An experimental investigation on energy-effective additive manufacturing of aluminum parts via process parameter selection[J]. Journal of Cleaner Production,2021,279:123609. doi: 10.1016/j.jclepro.2020.123609 -

下载:

下载: