Study of gas film thickness and its influence on electrochemical discharge machining

-

摘要: 玻璃作为一种非导电硬脆材料,在光学、生物医学、微机电系统等领域应用广泛。电化学放电加工作为针对绝缘硬脆材料的有效微细加工技术,可以在玻璃上进行有效的微结构加工。在电化学放电加工中,放电现象通过击穿气膜产生,气膜作为加工过程中最重要的介质,其质量是形成良好的表面微结构的重要因素。文章研究的重点是气膜特性及其对放电能量分布的影响。研究采用三因子三水平的全因子试验方法,以电源、占空比、频率三种电源参数为影响因子,气膜厚度为响应进行试验研究,获得最佳气膜质量的工艺参数组合。此外,在石英玻璃和K9光学玻璃两种玻璃上进行了微小孔加工的实验。结果表明,最佳工艺参数组合下能获得更薄气膜,同时也是获得更小径向过切、大的深径比、圆度误差较小的微小孔的最佳条件。Abstract: Glass is a non-conducting, hard and brittle material. It has a wide range of applications in optics, biomedicine and microelectromechanical systems. Electrochemical Discharge Machining (ECDM) is an effective microfabrication technique for insulating hard and brittle materials. It enables effective microstructural processing of glass. In ECDM, the discharge phenomenon is generated by the breakdown of the gas film, the quality of which, as the main medium in the process, is an important factor in forming good surface microstructures. This study focuses on the characteristics of the gas film and its influence on the discharge energy distribution. The study uses a full factorial test method with three factors and three levels of power supply, duty cycle and frequency as the influencing factors and gas film thickness as the response for the experimental study to obtain the best combination of process parameters for the best gas film quality. In addition, experiments were carried out on two types of glass, quartz glass and K9 optical glass, for the processing of micro-holes. The results show that the optimum combination of process parameters results in a thinner gas film and the best conditions for obtaining micro-holes with a smaller diameter overcut, a larger depth-to-diameter ratio and a smaller roundness error.

-

Key words:

- ECDM /

- gas film characteristics /

- parameter optimization /

- machining quality

-

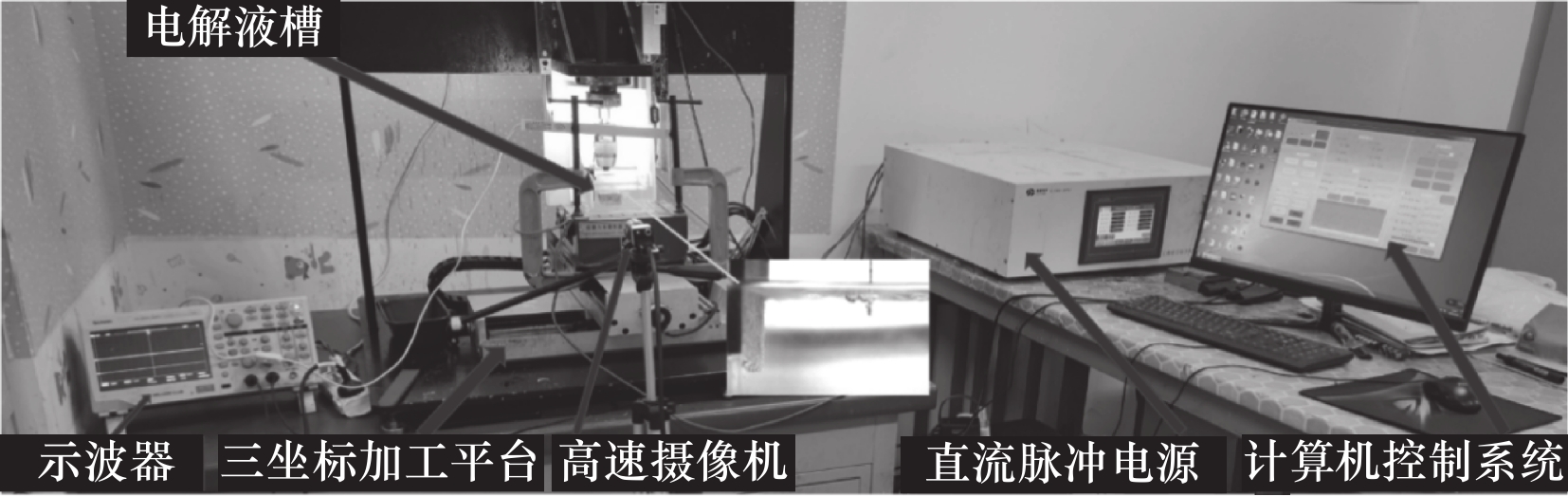

表 1 电化学放电加工各实验装置及材料参数

名称 参数 工件材料 光学玻璃、石英玻璃(h=1 mm) 工具电极 碳化钨(D=300 μm) 辅助阳极 石墨(50 mm×40 mm×4 mm) 电极间距/cm 3.5 电解液 NaOH 电解液浓度/(mol/L) 1 电解液水平/mm 5 表 2 考虑水平变化的工艺参数

因素 水平一 水平二 水平三 A:电压/V 50 55 60 B:频率/kHz 20 25 30 C:占空比/(%) 60 70 80 表 3 气膜厚度的方差分析

来源 自由度 Adj SS Adj MS F 值 P 值 模型 18 45 985.8 2 554.8 71.11 0.000 线性 6 33 495.8 55 826 155.39 0.000 A 2 31 108.1 15 554.0 432.95 0.000 B 2 7.2 3.6 0.10 0.906 C 2 2 380.5 1 190.3 33.13 0.000 2 因子交互作用 12 12 490.0 1 040.8 28.97 0.000 A*B 4 295.9 74.0 2.06 0.179 A*C 4 11 187.3 2 796.8 77.85 0.000 B*C 4 1 006.8 251.7 7.01 0.010 误差 8 287.4 35.9 合计 26 46 273.2 表 4 已确认的工艺参数组合

因素 最佳工艺参数组合 极端工艺参数组合 电压/V 50 60 频率/kHz 20 25 占空比/(%) 80 60 表 5 实验结果汇总

因素 石英玻璃 光学玻璃 最佳 极端 最佳 极端 径向过切/μm 69 150 100 169 圆度误差/μm 7 21 3 17.5 深径比 0.596 0.400 0.598 0.458 -

[1] Tölke R, Bieberle-Hütter A, Evans A, et al. Processing of foturan glass ceramic substrates for micro-solid oxide fuel cells[J]. Journal of the European Ceramic Society,2012,32(12):3229-3238. doi: 10.1016/j.jeurceramsoc.2012.04.006 [2] Ziaie B,Baldi A,Ming L,et al. Hard and soft micromachining for BioMEMS:review of techniques and examples of applications in microfluidics and drug delivery[J]. Advanced Drug Delivery Reviews,2004,56(2):145-172. doi: 10.1016/j.addr.2003.09.001 [3] Arab J,Mishra D K,Kannojia H K,et al. Fabrication of multiple through-holes in non-conductive materials by electrochemical discharge machining for RF MEMS packaging[J]. Journal of Materials Processing Technology,2019,271:542-553. doi: 10.1016/j.jmatprotec.2019.04.032 [4] Stjernström M,Roeraade J. Method for fabrication of microfluidic systems in glass[J]. Journal of Micromechanics and Microengineering,1998,8(1):33. doi: 10.1088/0960-1317/8/1/006 [5] Perveen A, Molardi C. Machining of glass materials: An overview[J]. Advanced Manufacturing Technologies: Modern Machining, Advanced Joining, Sustainable Manufacturing, 2017: 23-47. [6] Ahmed N,Darwish S,Alahmari A M. Laser ablation and laser-hybrid ablation processes:a review[J]. Materials and Manufacturing Processes,2016,31(9):1121-1142. doi: 10.1080/10426914.2015.1048359 [7] Sharma A,Jain V,Gupta D. Comparative analysis of chipping mechanics of float glass during rotary ultrasonic drilling and conventional drilling:For multi-shaped tools[J]. Machining Science and Technology,2019,23(4):547-568. doi: 10.1080/10910344.2019.1575402 [8] Huu Loc P,Shiou F J,Yu Z R,et al. Investigation of optimal air-driving fluid jet polishing parameters for the surface finish of N-BK7 optical glass[J]. Journal of Manufacturing Science and Engineering,2013,135(1):011015. doi: 10.1115/1.4023368 [9] Wang Z,Li H N,Yu T B,et al. Analytical model of dynamic and overlapped footprints in abrasive air jet polishing of optical glass[J]. International Journal of Machine Tools and Manufacture,2019,141:59-77. doi: 10.1016/j.ijmachtools.2019.03.005 [10] Kumar S,Dvivedi A. On effect of tool rotation on performance of rotary tool micro-ultrasonic machining[J]. Materials and Manufacturing Processes,2019,34(5):475-486. doi: 10.1080/10426914.2018.1512130 [11] Foucault M L. Experiments with the light of the voltaic arc[J]. Journal of the Franklin Institute,1849,48(1):50-52. [12] Kurafuji H,Suda H. Electrical discharge drilling of glass[J]. Ann. CIRP,1968,16:415-419. [13] Wüthrich R,Bleuler H. A model for electrode effects using percolation theory[J]. Electrochimica Acta,2004,49(9-10):1547-1554. doi: 10.1016/j.electacta.2003.11.014 [14] Wüthrich R,Hof L A,Lal A,et al. Physical principles and miniaturization of spark assisted chemical engraving (SACE)[J]. Journal of Micromechanics and Microengineering,2005,15(10):S268. doi: 10.1088/0960-1317/15/10/S03 [15] Cheng C P,Wu K L,Mai C C,et al. Study of gas film quality in electrochemical discharge machining[J]. International Journal of Machine Tools and Manufacture,2010,50(8):689-697. doi: 10.1016/j.ijmachtools.2010.04.012 [16] Kolhekar K R,Sundaram M. Study of gas film characterization and its effect in electrochemical discharge machining[J]. Precision Engineering,2018,53:203-211. doi: 10.1016/j.precisioneng.2018.04.002 [17] Singh T,Dvivedi A. Impact of gas film thickness on the performance of RM-ECDM process during machining of glass[J]. Materials and Manufacturing Processes,2022,37(6):652-663. doi: 10.1080/10426914.2021.1945092 [18] Goud M,Sharma A K,Jawalkar C. A review on material removal mechanism in electrochemical discharge machining (ECDM) and possibilities to enhance the material removal rate[J]. Precision Engineering,2016,45:1-17. doi: 10.1016/j.precisioneng.2016.01.007 [19] Wei C,Xu K,Ni J,et al. A finite element based model for electrochemical discharge machining in discharge regime[J]. The International Journal of Advanced Manufacturing Technology,2011,54:987-995. doi: 10.1007/s00170-010-3000-0 [20] Kolhekar K,Sundaram M. A multiphase simulation study of electrochemical discharge machining of glass[J]. The International Journal of Advanced Manufacturing Technology,2019,105:1597-1608. doi: 10.1007/s00170-019-04318-5 [21] Leyva-Bravo J,Chiñas-Sanchez P,Hernandez-Rodriguez A,et al. Electrochemical discharge machining modeling through different soft computing approaches[J]. The International Journal of Advanced Manufacturing Technology,2020,106:3587-3596. doi: 10.1007/s00170-019-04766-z -

下载:

下载: