Polar pixel layout method for obtaining the profile of the spiral groove end section of end mill

-

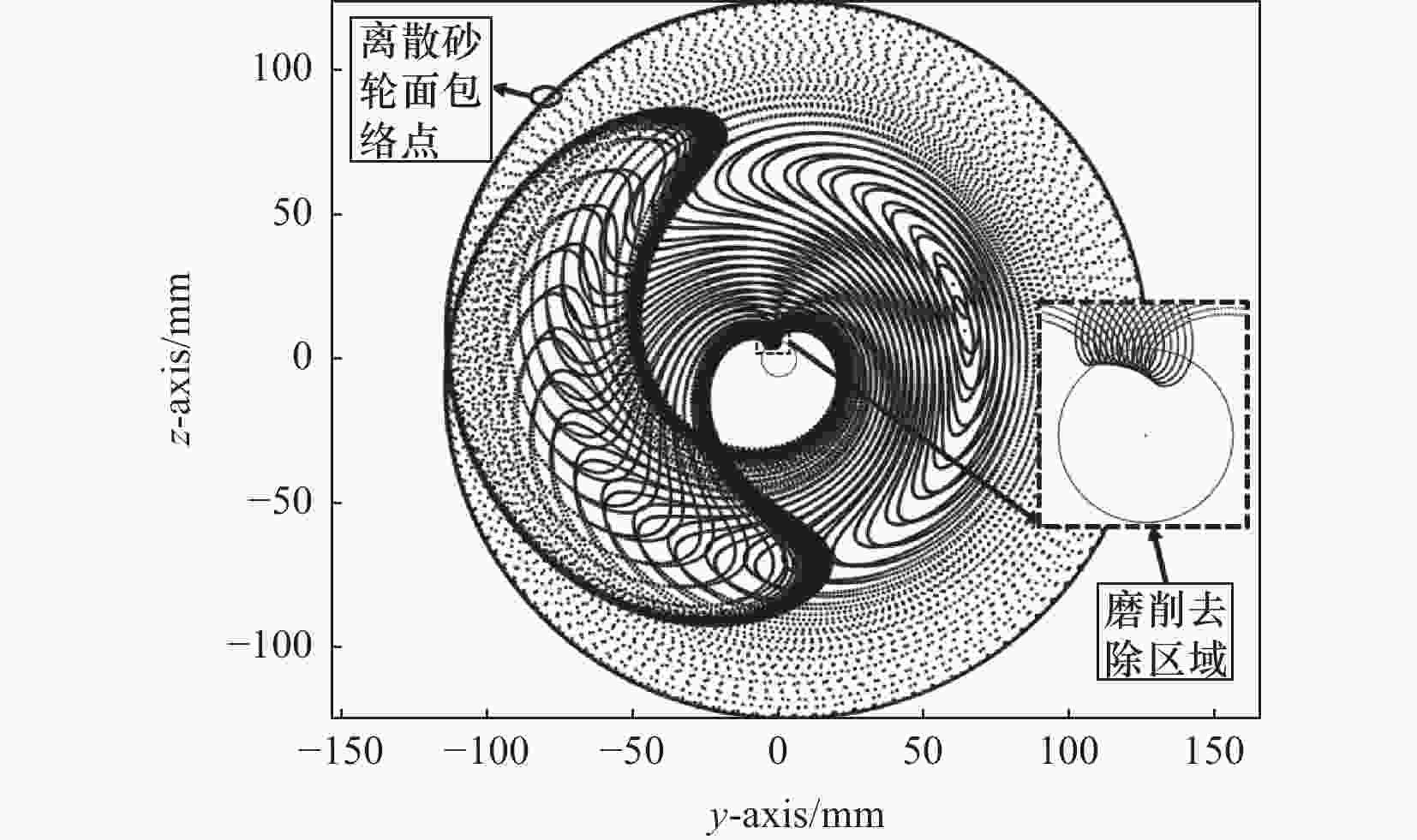

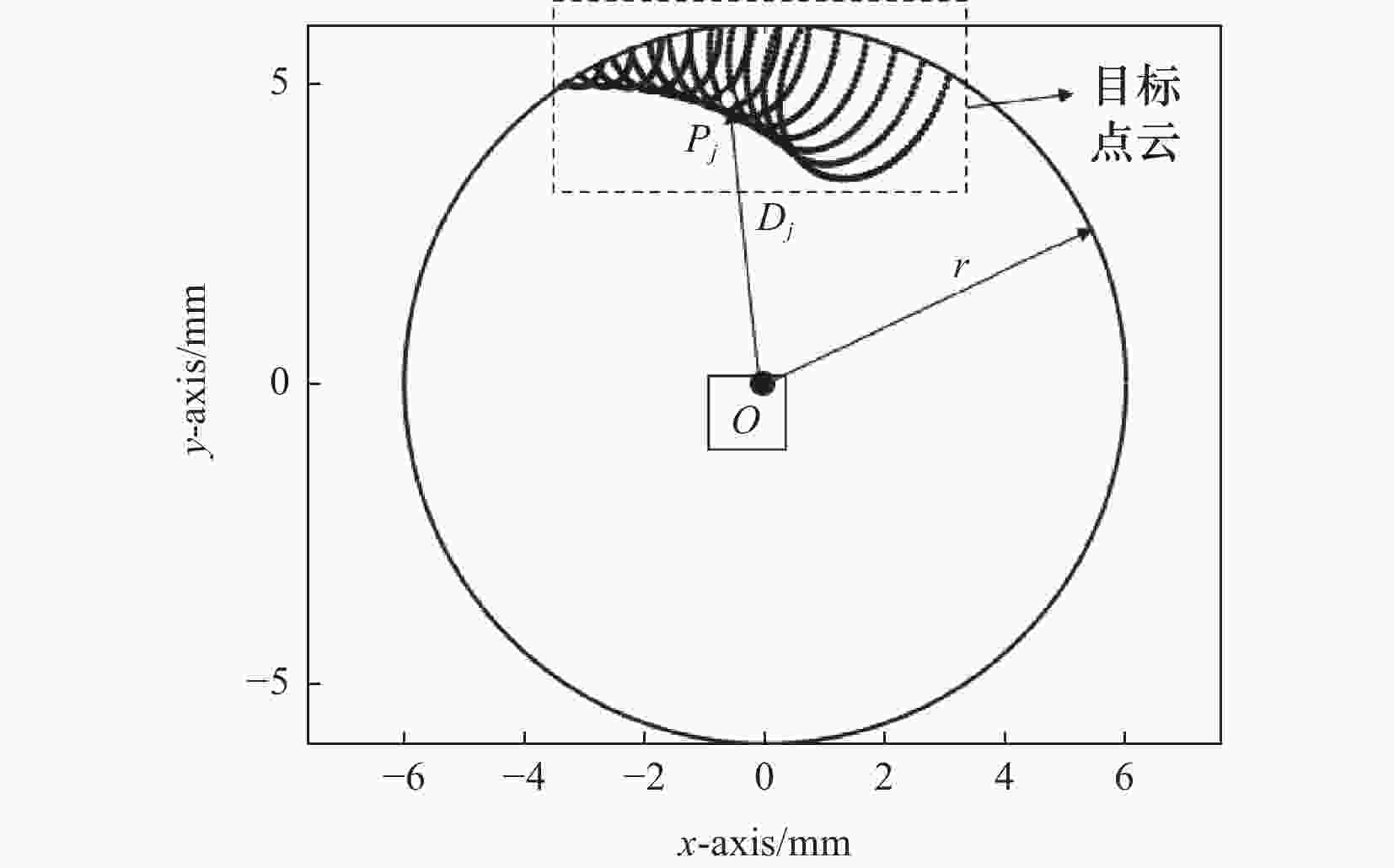

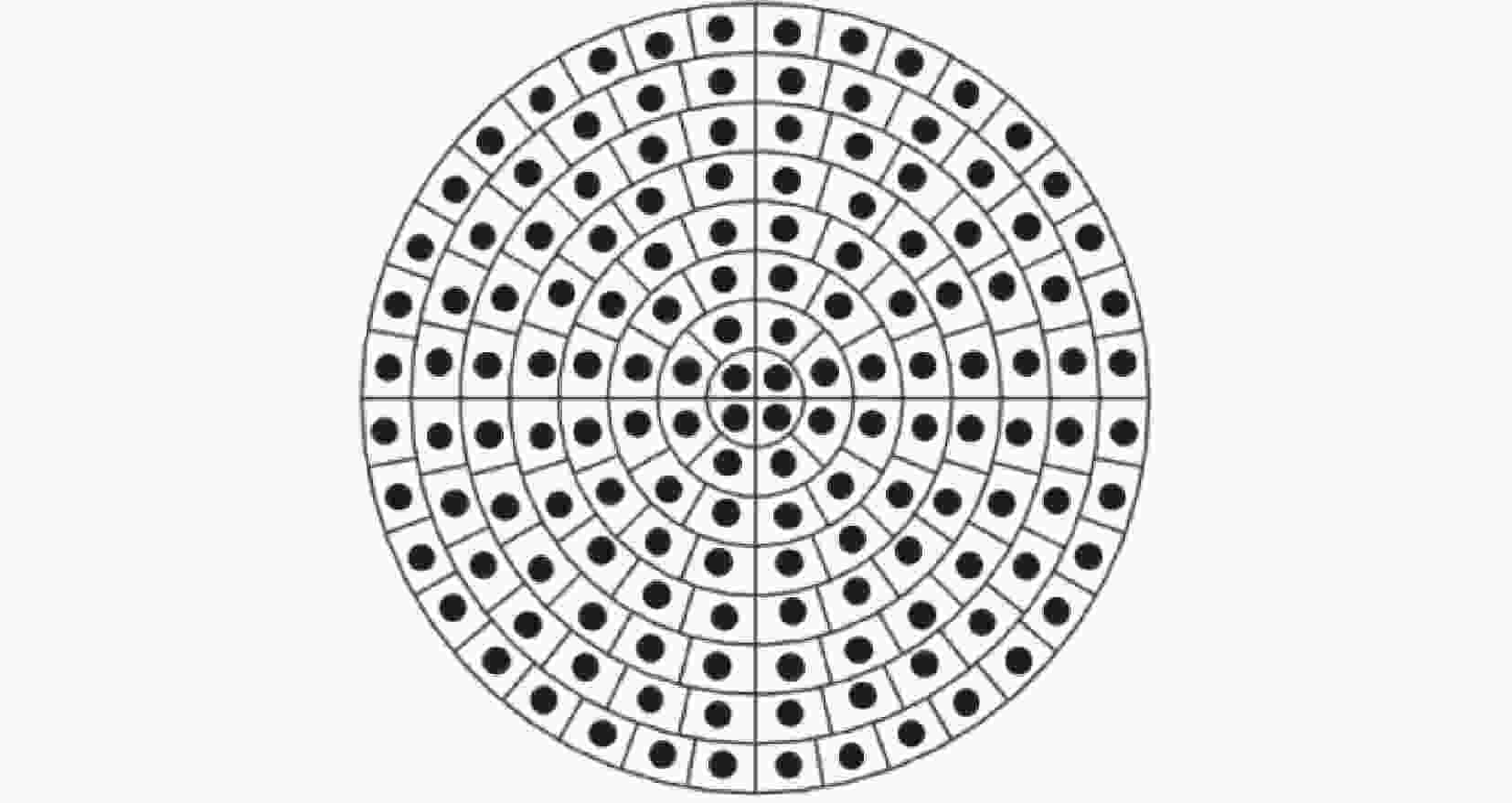

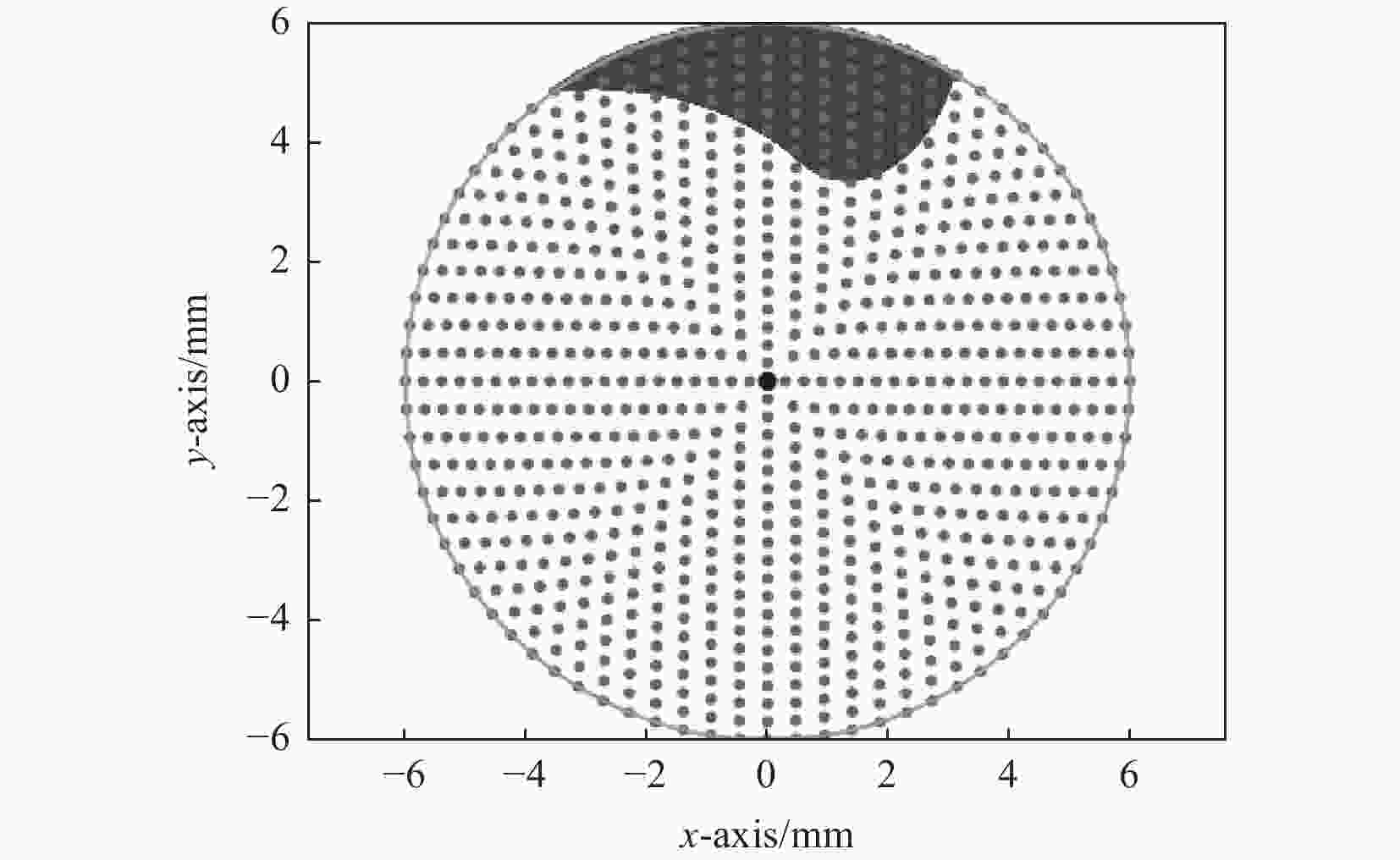

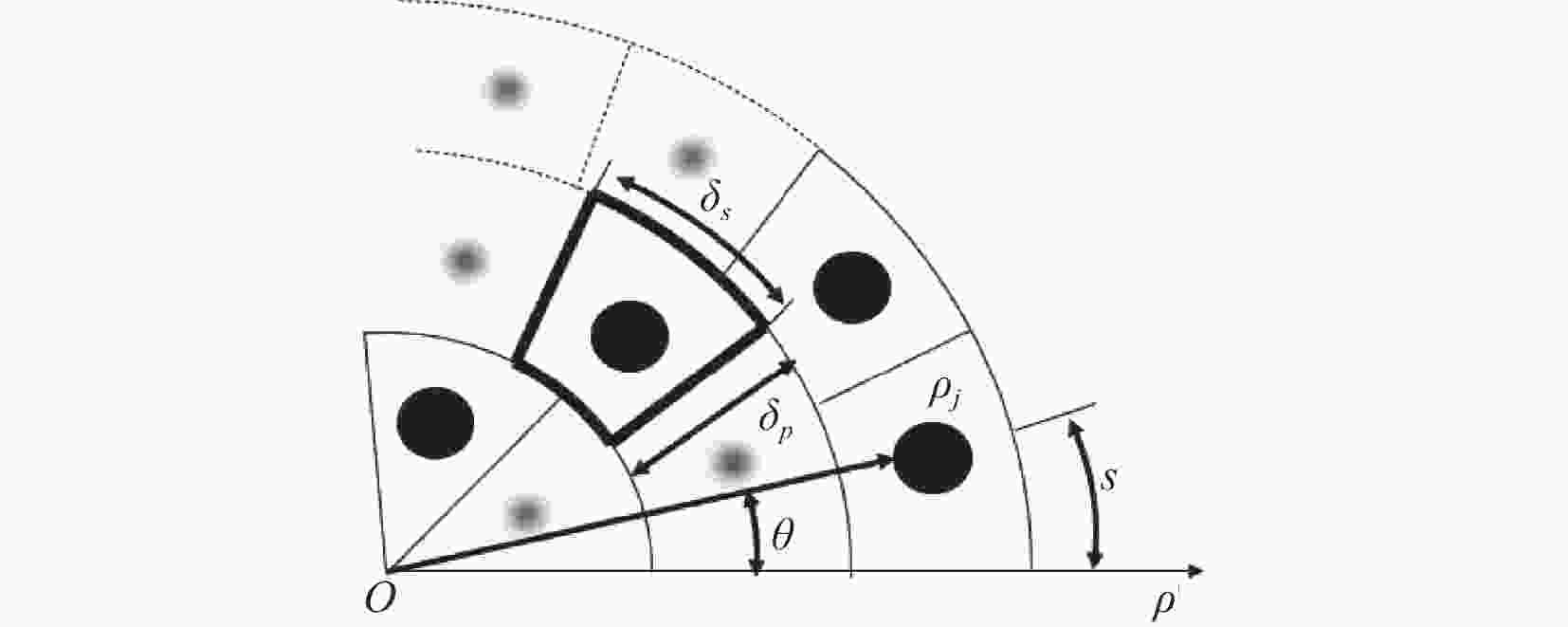

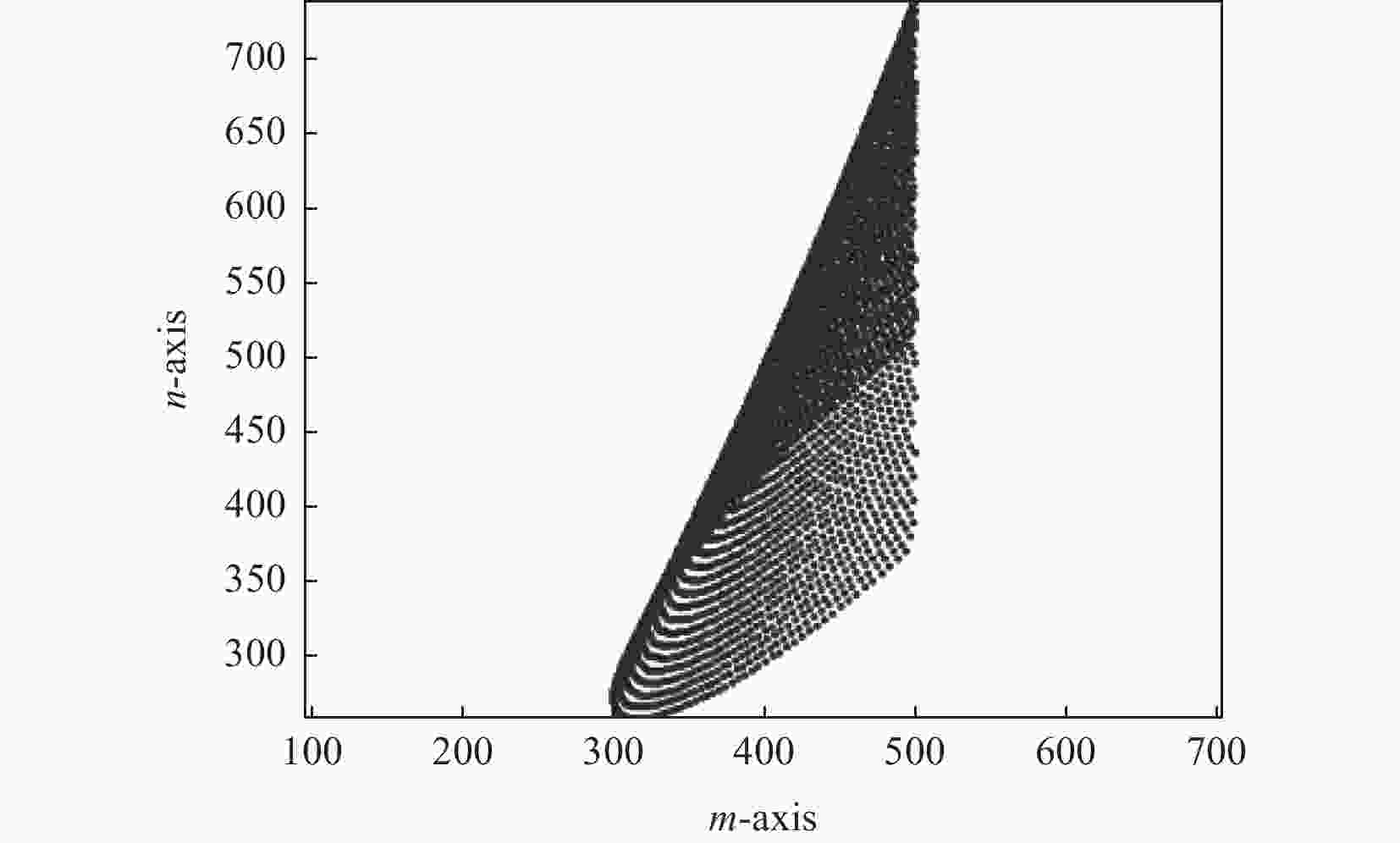

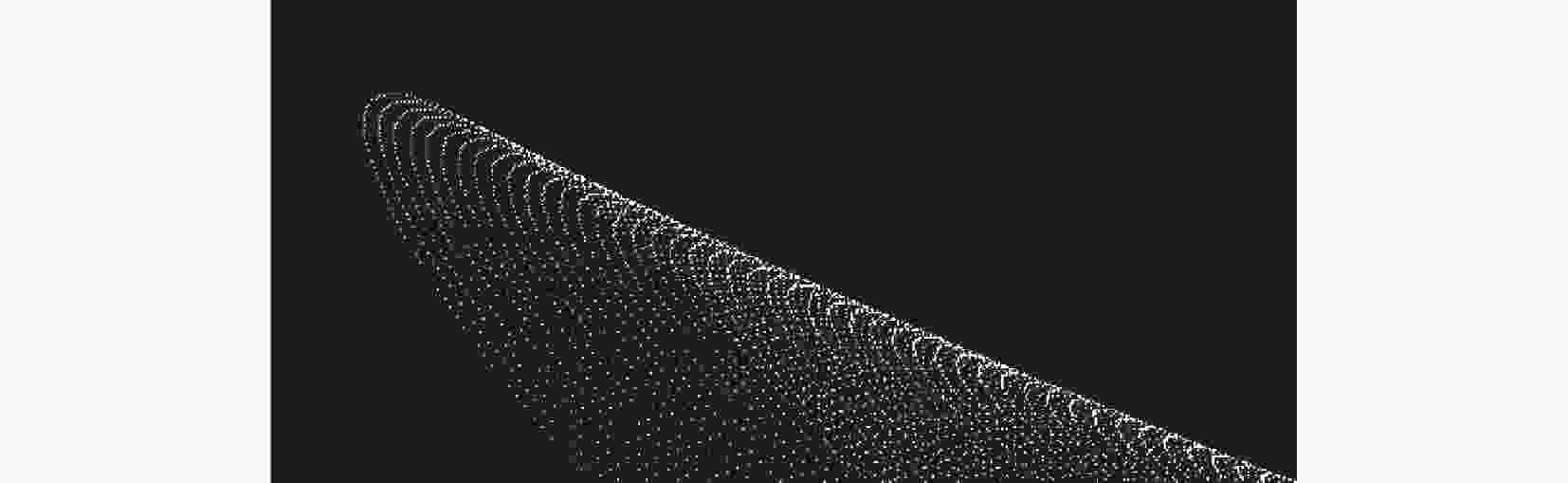

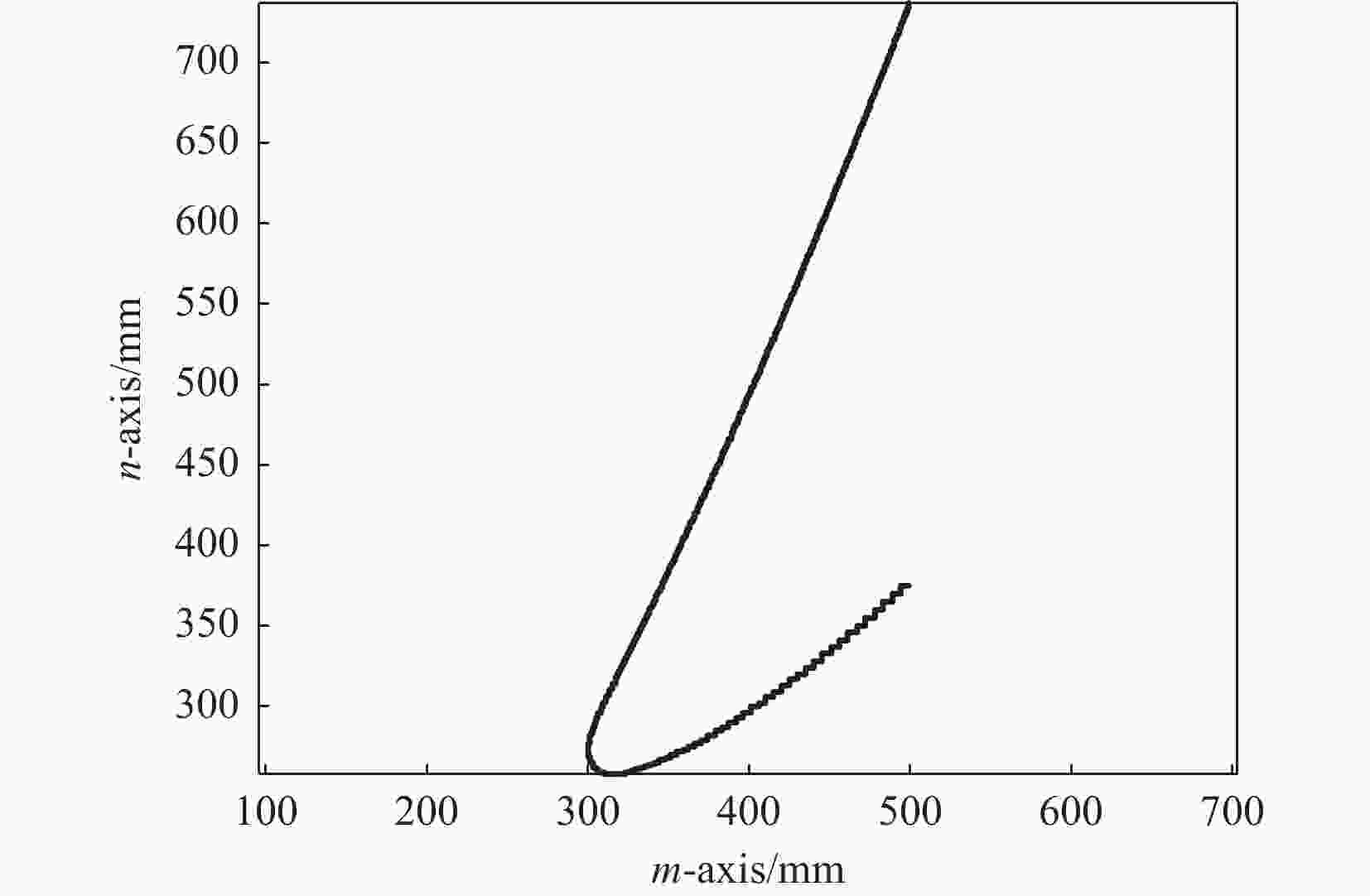

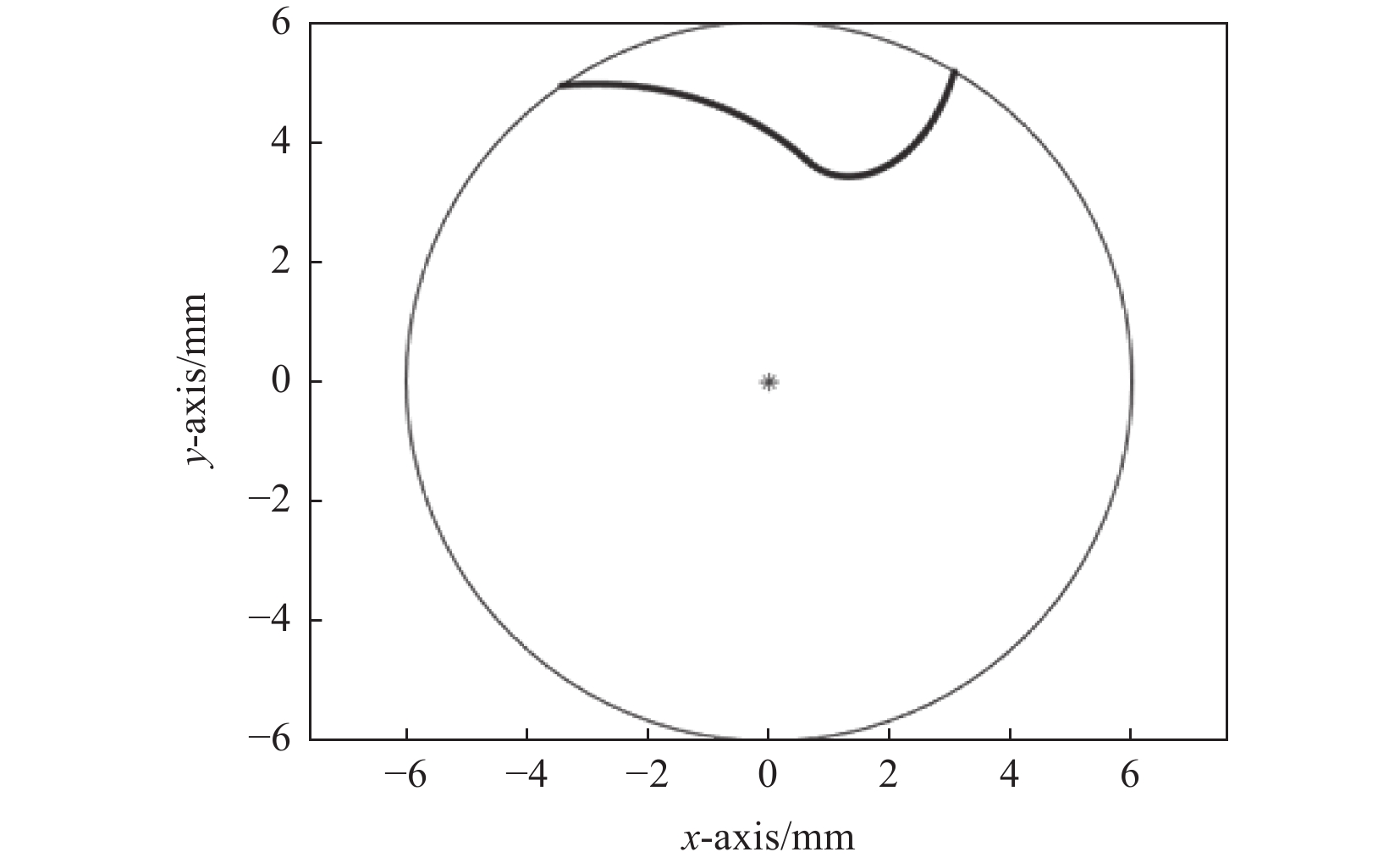

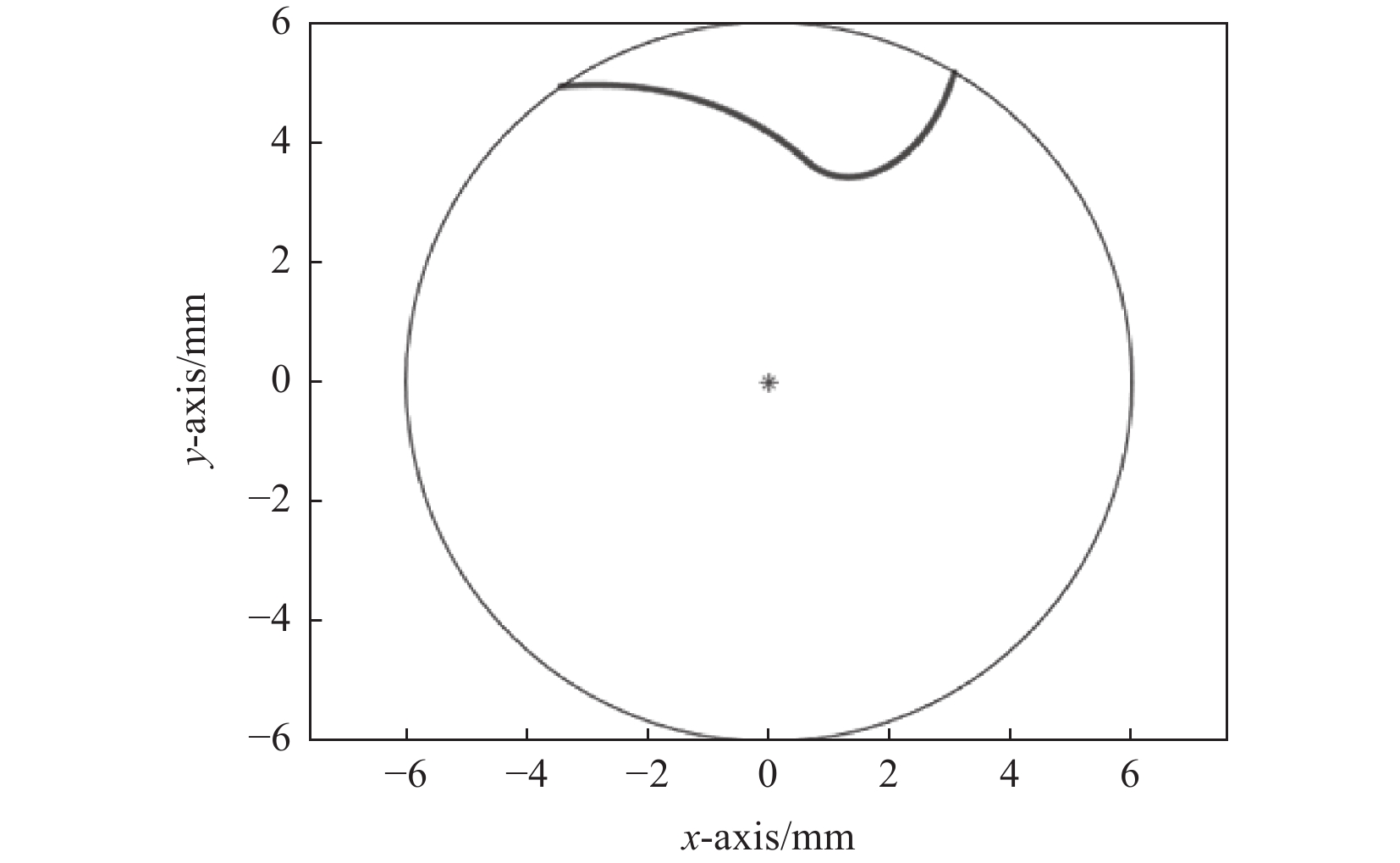

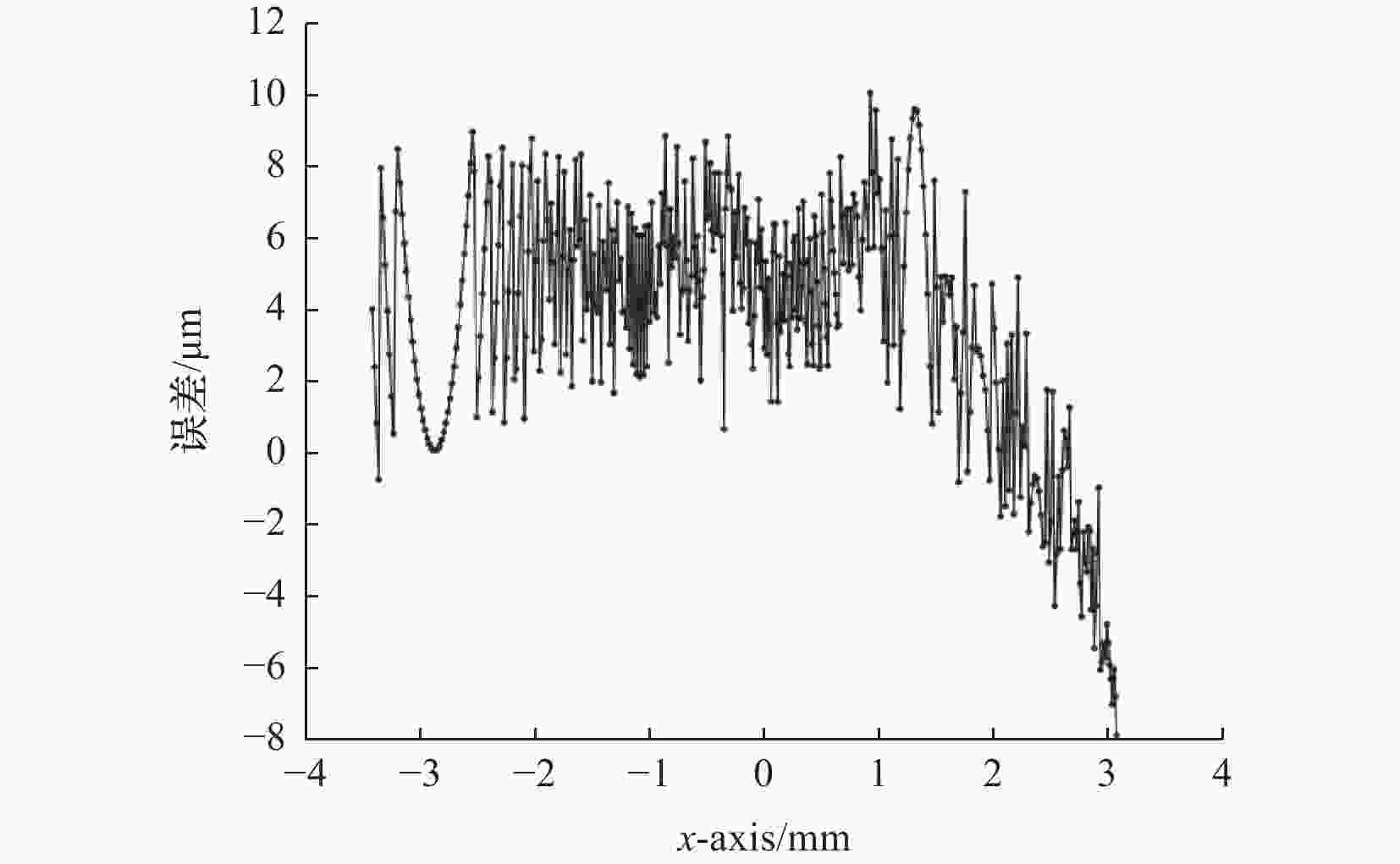

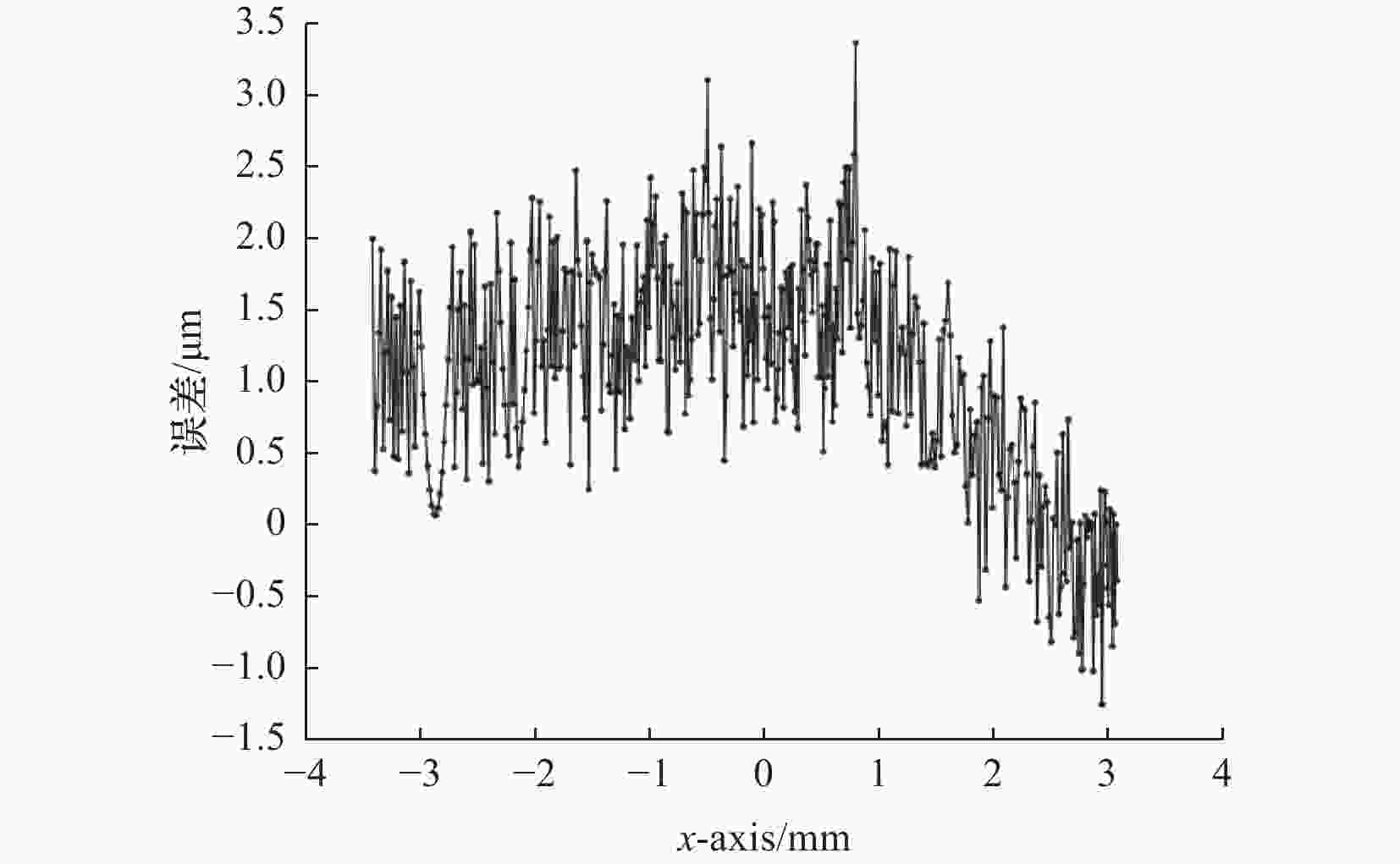

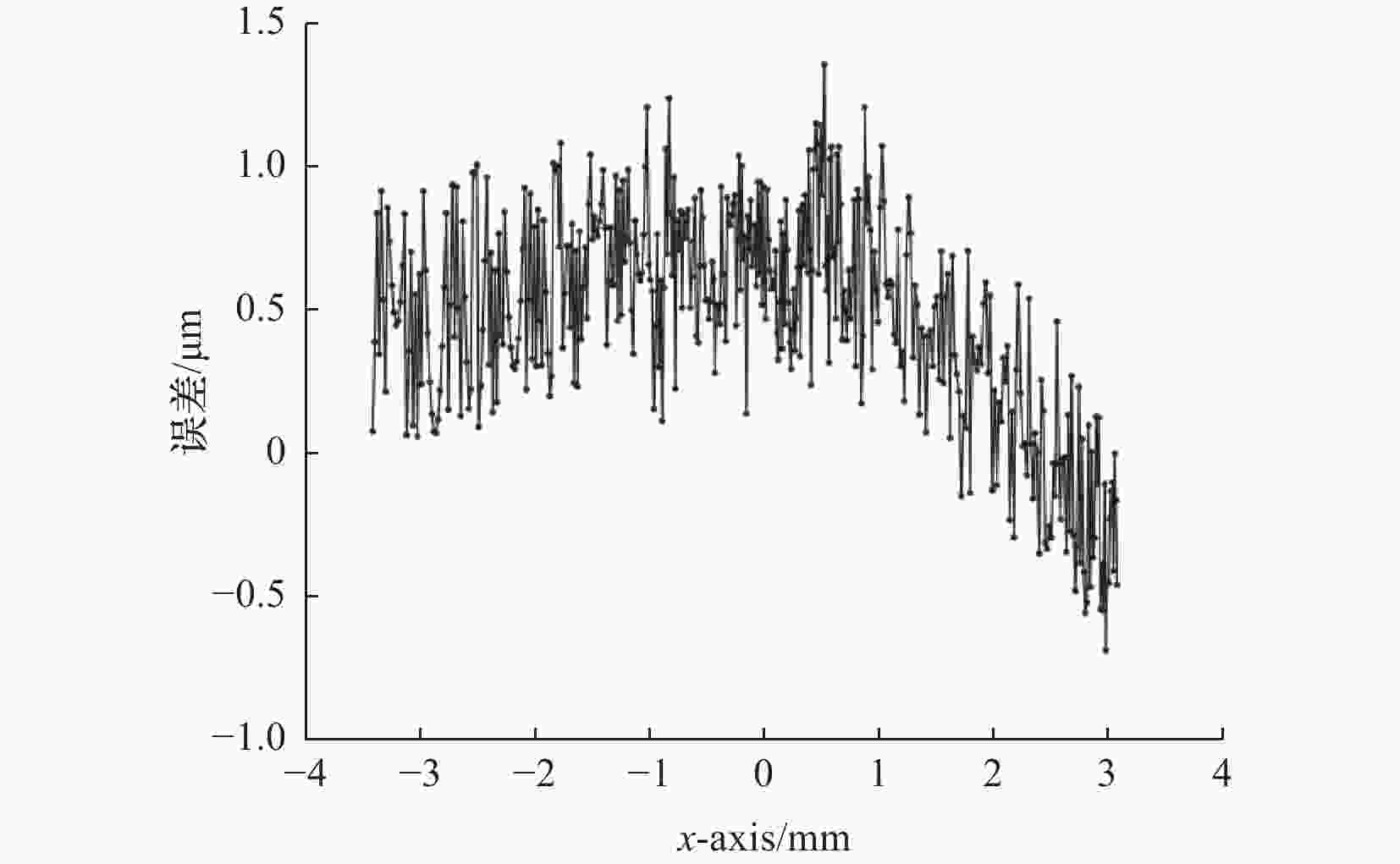

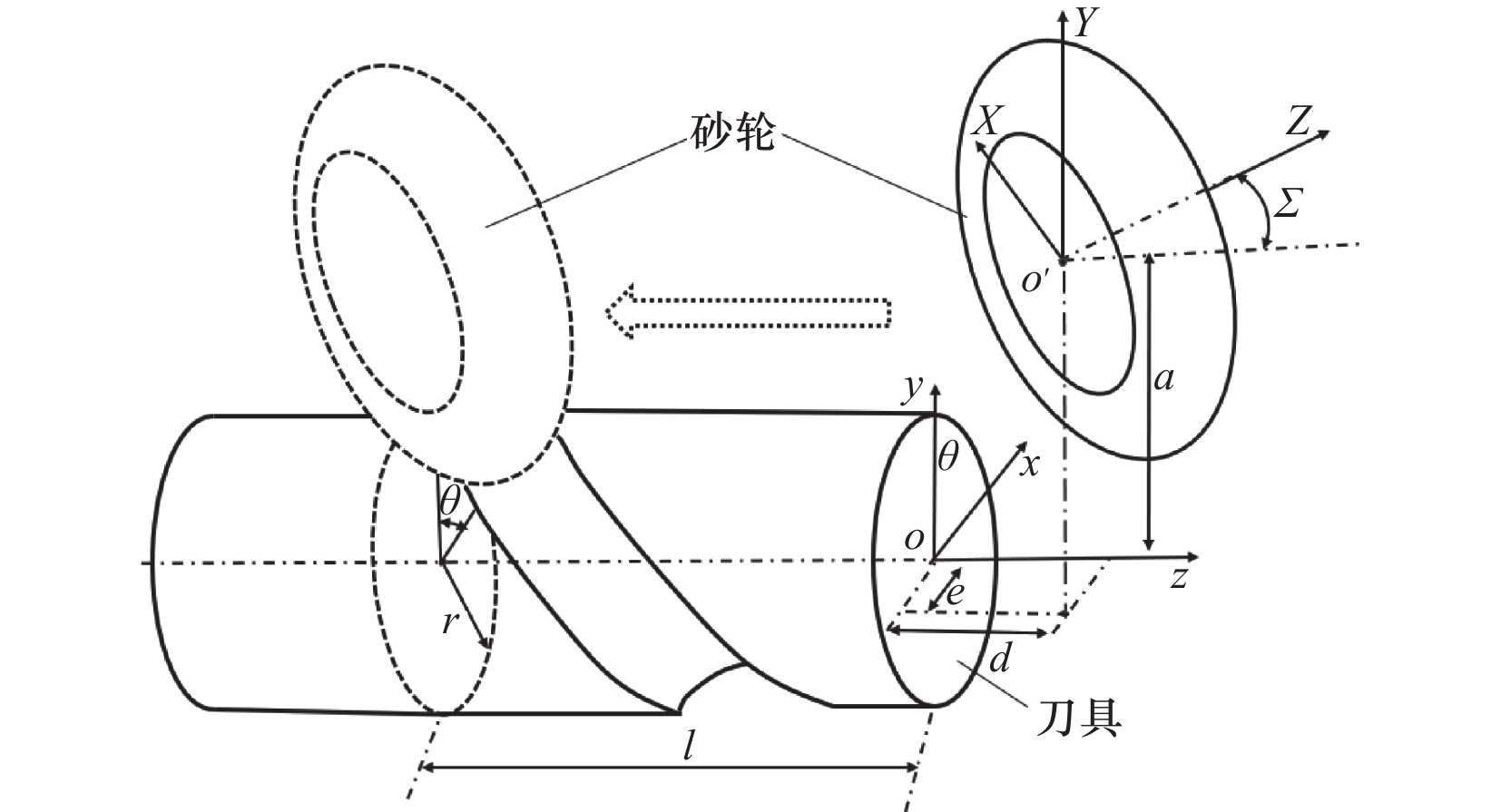

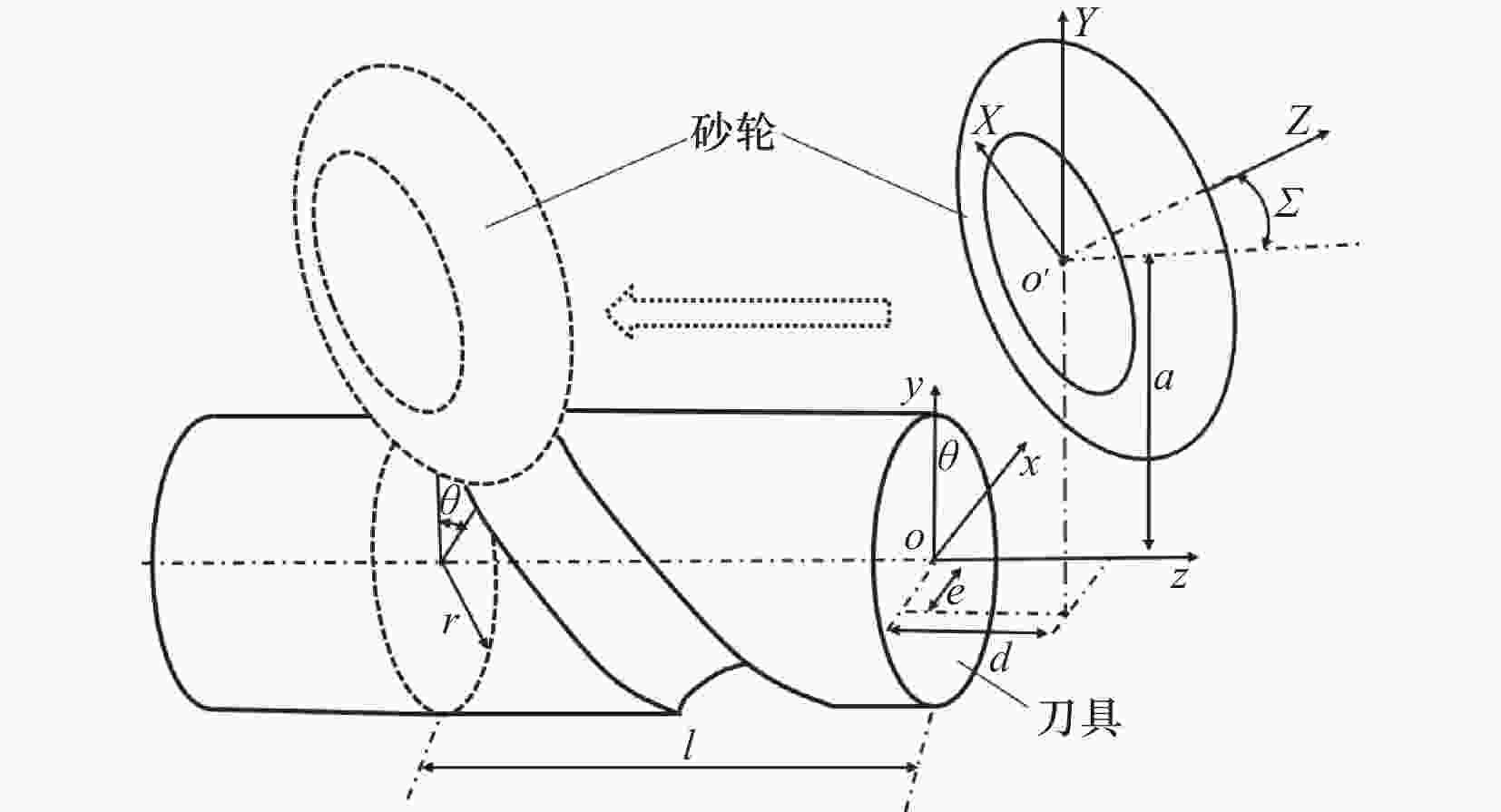

摘要: 立铣刀螺旋槽端截面廓形是刀具设计、加工与性能分析的重要因素。文章以砂轮螺旋运动结合极坐标变换和数学形态学,提出了一种获取整体式立铣刀螺旋槽端截面廓形的新方法,简称极坐标像素平铺(PPM)法。该方法直接通过点云极坐标二值图像结合提取数学形态学的膨胀和腐蚀算法操作提取截形边界,无需求解接触线方程,能稳定获得高精度立铣刀螺旋槽端截面廓形。最后将PPM法计算结果与解析法计算结果进行比较,结果显示两者比较误差均在许可范围内,从而验证了PPM法的正确性和有效性。Abstract: The profile of the end section of the flute is an important factor in tool design, machining and performance analysis. In this paper, a new method, polar pixel layout method (PPM), is proposed to obtain the profile of the flute end section of an end mill by combining the spiral motion of the grinding wheel with polar coordinate transformation and mathematical morphology. PPM extracts the section profile directly through the polar coordinate binary image of the point cloud combined with the erosion and dilation algorithm of mathematical morphology. It does not need to solve the contact line equation, nor do Boolean operations. PPM can stably obtain the high-precision profile of the flute of the end mill. Finally, PPM calculation results are compared with the analytical method. These comparison errors are within the allowable range, thus verifying the correctness and effectiveness of PPM.

-

Key words:

- spiral movement /

- mathematical morphology /

- integral end mill /

- end section /

- polar coordinates

-

表 1 刀具参数表

参数 数值 刀具外径r/mm 6 螺旋角β/(°) 30 刃数 4 表 2 砂轮参数表

参数 数值 中心距a/mm 63.738 偏心距e/mm 9.884 砂轮摆角Σ/(°) 32 表 3 安装参数表

参数 数值 中心距a/mm 63.738 偏心距e/mm 9.884 砂轮摆角Σ/(°) 32 -

[1] Wang L , Li J , Chen Z C , et al. An efficient approach to calculating the moment of inertia of solid end-mill flutes[C]. International Conference on Innovative Design & Manufacturing. IEEE, 2014. [2] Li G C,Zhou H G,Jing X W,et al. Modeling of integral cutting tool grooves using envelope theory and numerical methods[J]. The International Journal of Advanced Manufacturing Technology,2018,98:579-591. doi: 10.1007/s00170-018-2181-9 [3] Li G C,Dai L,Zhou H,et al. An approach to calculate grinding wheel path for complex end mill groove grinding based on an optimization algorithm[J]. Journal of Manufacturing Processes,2020,53:99-109. doi: 10.1016/j.jmapro.2020.02.011 [4] Beju L , Dan P B , Mutiu N C , et al. Modeling, simulation and manufacturing of drill flutes[J]. The International Journal of Advanced Manufacturing Technology, 2016, 83(9-12): 2111-2127. [5] Li G. A new algorithm to solve the grinding wheel profile for end mill groove machining[J]. International Journal of Advanced Manufacturing Technology,2017,90:775-784. doi: 10.1007/s00170-016-9408-4 [6] Kang S K,Ehmann K F,Lin C. A CAD approach to helical groove machining:I. mathematical model and model solution[J]. International Journal of Machine Tools and Manufacture,1996,36(1):141-153. doi: 10.1016/0890-6955(95)92631-8 [7] Kang S K,Ehmann K F,Lin C. A CAD approach to helical groove machining. Part 2:Numerical evaluation and sensitivity analysis[J]. International Journal of Machine Tools and Manufacture,1997,37(1):101-117. doi: 10.1016/0890-6955(95)00039-9 [8] Dogrusadik A. Equation of the cross-sectional profile of a groove produced by helical milling with a ball-end mill[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2022,44(7):1-8. [9] Rababah M. A practical and optimal approach to CNC programming for five-axis grinding of the end-mill flutes[D]. Montreal: Concordia University, 2011. [10] Habibi M,Chen Z C. A generic and efficient approach to determining locations and orientations of complex standard and worn wheels for cutter flute grinding using characteristics of virtual grinding curves[J]. Journal of Manufacturing Science and Engineering,2017,139(4):041018. doi: 10.1115/1.4035421 [11] Chen Z,Liu X L,He G H,et al. An iteration-based algorithm for two-pass flute grinding of slide round milling tools[J]. The International Journal of Advanced Manufacturing Technology,2020,111:2533-2543. doi: 10.1007/s00170-020-06278-7 [12] Shen C Q,Xiao Y M,Xiong SL. Grinding wheel parametric design for machining arbitrary grooves on the helical rake face of the tool[J]. International Journal of Precision Engineering and Manufacturing-Green Technology,2022,9(4):997-1008. doi: 10.1007/s40684-021-00372-1 [13] Kim J H,Park J W,Ko T J. End mill design and machining via cutting simulation[J]. Computer-Aided Design,2008,40(3):324-333. doi: 10.1016/j.cad.2007.11.005 [14] Pei Q, Li Z, Cui X, et al. A practical method of modelling and simulation for ball end mill CNC grinding[C]. IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2019, 688(3): 033035. [15] Li G C,Sun J,Li J F. Process modeling of end mill groove machining based on Boolean method[J]. The International Journal of Advanced Manufacturing Technology,2014,75:959-966. doi: 10.1007/s00170-014-6187-7 [16] Tost D,Puig A,Pérez-vidal L. Boolean operations for 3D simulation of CNC machining of drilling tools[J]. Computer-Aided Design,2004,36(4):315-323. doi: 10.1016/S0010-4485(03)00104-0 [17] Trung Thanh Pham, Sung Lim Ko .A manufacturing model of an end mill using a five-axis CNC grinding machine[J]. International Journal of Advanced Manufacturing Technology, 2010, 48: 461-472. [18] Li G C,Sun J,Li J F. Modeling and analysis of helical groove grinding in end mill machining[J]. Journal of Materials Processing Technology,2014,214(12):3067-3076. doi: 10.1016/j.jmatprotec.2014.07.009 [19] Wu Y R,Fong Z H,Zhang Z X. Simulation of a cylindrical form grinding process by the radial-ray shooting (RRS) method[J]. Mechanism and Machine Theory,2010,45(2):261-272. doi: 10.1016/j.mechmachtheory.2009.09.005 [20] Shen Z H,Yao B,Teng W B,et al. Generating grinding profile between screw rotor and forming tool by digital graphic scanning (DGS) method[J]. International Journal of Precision Engineering and Manufacturing,2016,17(1):35-41. doi: 10.1007/s12541-016-0005-0 [21] Xin Y,Pawlak M,Liao S. Accurate computation of zernike moments in polar coordinates[J]. IEEE Transactions on Image Processing A Publication of the IEEE Signal Processing Society,2007,16:581. doi: 10.1109/TIP.2006.888346 [22] Dougherty E. Mathematical morphology in image processing[M]. CRC Press, 2018. [23] Šostak A, Uljane I, Eklund P. Fuzzy relational mathematical morphology: erosion and dilation[C]. International Conference on Information Processing and Management of Uncertainty in Knowledge-Based Systems. Springer, Cham, 2020: 712-725. [24] Jos Roerdink. Mathematical morphology in image processing[M]. Florida: CRC Press, 2018. -

下载:

下载: