| [1] |

Pan C R,Zhou M C,Qiao Y,et al. Scheduling cluster tools in semiconductor manufacturing:Recent advances and challenges[J]. IEEE Transactions on Automation Science and Engineering,2018,15(2):586-601. doi: 10.1109/TASE.2016.2642997

|

| [2] |

袁凤连,黄波,王际鹏,等. 基于Petri网的组合设备建模与调度综述[J]. 自动化学报,2023,49(5):929-948. doi: 10.16383/j.aas.c210951

|

| [3] |

Zhu Q H,Wu N Q,Qiao Y,et al. Petri net-based optimal one-wafer scheduling of single-arm multi-cluster tools in semiconductor manufacturing[J]. IEEE Transactions on Semiconductor Manufacturing,2013,26(4):578-591. doi: 10.1109/TSM.2013.2278378

|

| [4] |

Zhu Q H,Wu N Q,Qiao Y,et al. Scheduling of single-arm multi-cluster tools with wafer residency time constraints in semiconductor manufacturing[J]. IEEE Transactions on Semiconductor Manufacturing,2015,28(1):117-125. doi: 10.1109/TSM.2014.2375880

|

| [5] |

Zhu Q H,Wu N Q,Qiao Y,et al. Optimal scheduling of complex multi-cluster tools based on timed resource-oriented Petri nets[J]. IEEE Access,2016,4:2096-2109. doi: 10.1109/ACCESS.2016.2549546

|

| [6] |

Yang F J,Wu N Q,Qiao Y,et al. Petri net-based efficient determination of optimal schedules for transport-dominant single-arm multi-cluster tools[J]. IEEE Access,2018,6:355-365. doi: 10.1109/ACCESS.2017.2763778

|

| [7] |

Bao T P,Wang H G. Cyclic scheduling of multi-cluster tools based on mixed integer programming[J]. IEEE Transactions on Semiconductor Manufacturing,2017,30(4):515-525. doi: 10.1109/TSM.2017.2733559

|

| [8] |

Yan Y Y,Wang H G,Tao Q H,et al. Noncyclic scheduling of multi-cluster tools with residency constraints based on Pareto optimization[J]. IEEE Transactions on Semiconductor Manufacturing,2020,33(3):476-486. doi: 10.1109/TSM.2020.2998734

|

| [9] |

Zhu Q H,Qiao Y,Wu N Q. Optimal integrated schedule of entire process of dual-blade multi-cluster tools from start-up to close-down[J]. IEEE/CAA Journal of Automatica Sinica,2019,6(2):553-565. doi: 10.1109/JAS.2019.1911411

|

| [10] |

Yang F J,Wu N Q,Qiao Y,et al. Wafer sojourn time fluctuation analysis for time-constrained dual-arm multi-cluster tools with activity time variation[J]. International Journal of Computer Integrated Manufacturing,2020,34(7-8):734-751.

|

| [11] |

Zhu Q H,Wang G H,Hou Y,et al. Optimally scheduling dual-arm multi-cluster tools to process two wafer types[J]. IEEE Robotics and Automation Letters,2022,7(3):5920-5927. doi: 10.1109/LRA.2022.3157031

|

| [12] |

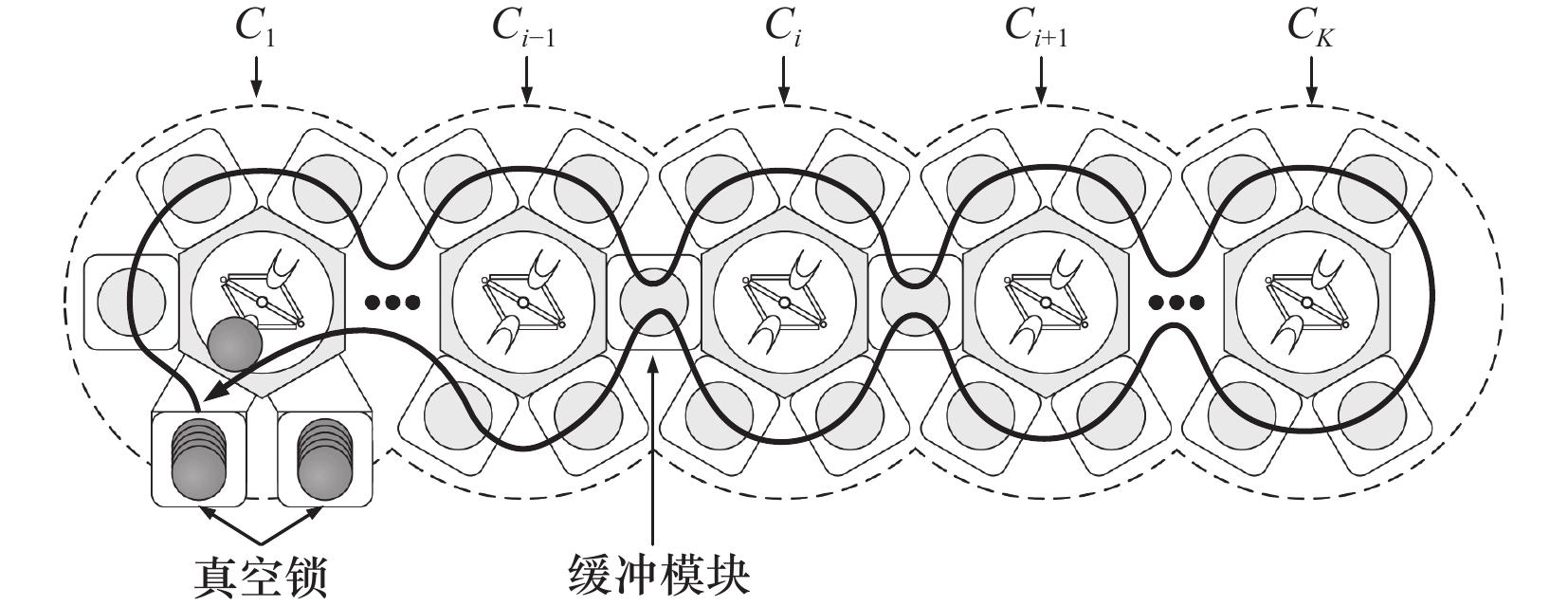

Yang F J,Wu N Q,Qiao Y,et al. Optimal one-wafer cyclic scheduling of single-arm multicluster tools with two-space buffering modules[J]. IEEE Transactions on Systems,Man,Cybernetics-Systems,2014,44(12):1584-1597.

|

| [13] |

李文涛,白丽平,伍乃骐,等. 具有2-空间缓冲模块的多组合设备的优化调度[J]. 系统工程理论与实践,2016,36(9):2408-2415. doi: 10.12011/1000-6788(2016)09-2408-08

|

| [14] |

黄鹏,白丽平,朱清华. 缓冲区容量为2的单臂树形多组合设备的建模与调度[J]. 系统工程理论与实践,2018,38(12):3244-3252. doi: 10.12011/1000-6788(2018)12-3244-09

|

| [15] |

Bai L P,Wu N Q,Li Z W,et al. Optimal one-wafer cyclic scheduling and buffer space configuration for single-arm multicluster tools with linear topology[J]. IEEE Transactions on Systems,Man,Cybernetics-Systems,2016,46(10):1456-1467.

|

| [16] |

Yang F J,Wu N Q,Qiao Y,et al. Petri net-based optimal one-wafer cyclic scheduling of hybrid multi-cluster tools in wafer fabrication[J]. IEEE Transactions on Semiconductor Manufacturing,2014,27(2):192-203. doi: 10.1109/TSM.2014.2312192

|

| [17] |

Yang F J,Wu N Q,Qiao Y,et al. Petri net-based polynomially complex approach to optimal one-wafer cyclic scheduling of hybrid multi-cluster tools in semiconductor manufacturing[J]. IEEE Transactions on Systems,Man,Cybernetics-Systems,2014,44(12):1598-1610.

|

| [18] |

Yang F J,Wu N Q,Qiao Y,et al. Optimal one-wafer cyclic scheduling of time-constrained hybrid multicluster tools via Petri nets[J]. IEEE Transactions on Systems,Man,Cybernetics-Systems,2017,47(11):2920-2932.

|

| [19] |

Yang F J,Wu N Q,Qiao Y,et al. Optimal one-wafer cyclic scheduling of hybrid multirobot cluster tools with tree topology[J]. IEEE Transactions on Systems,Man,Cybernetics-Systems,2018,48(2):289-298.

|

| [20] |

Yang F J,Wu N Q,Qiao Y,et al. Polynomial approach to optimal one-wafer cyclic scheduling of treelike hybrid multi-cluster tools via Petri nets[J]. IEEE/CAA Journal of Automatica Sinica,2018,5(1):270-280. doi: 10.1109/JAS.2017.7510772

|

下载:

下载: