Effect of micro-textures on the friction and wear characteristics of V-shaped sliding guideways

-

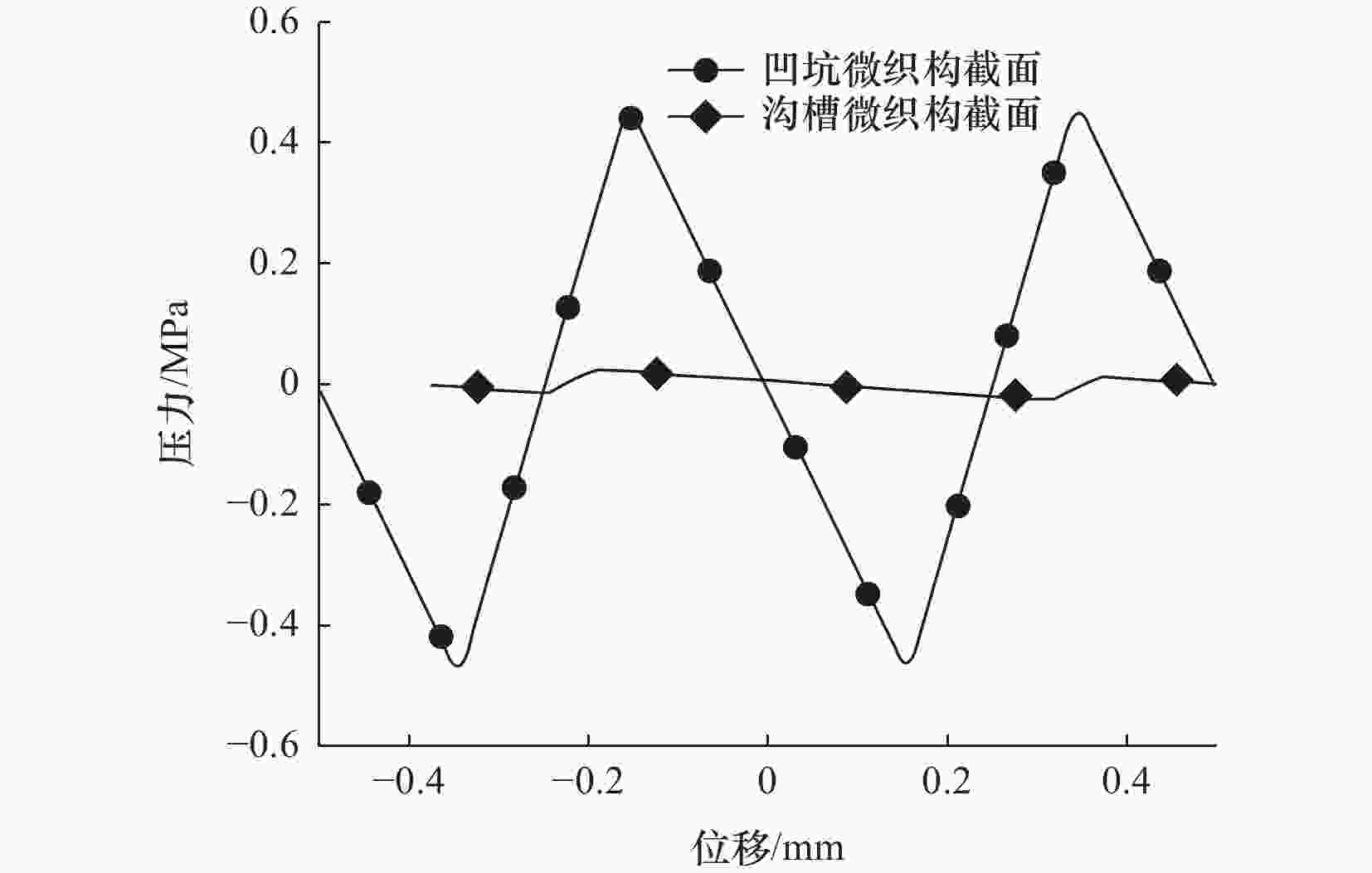

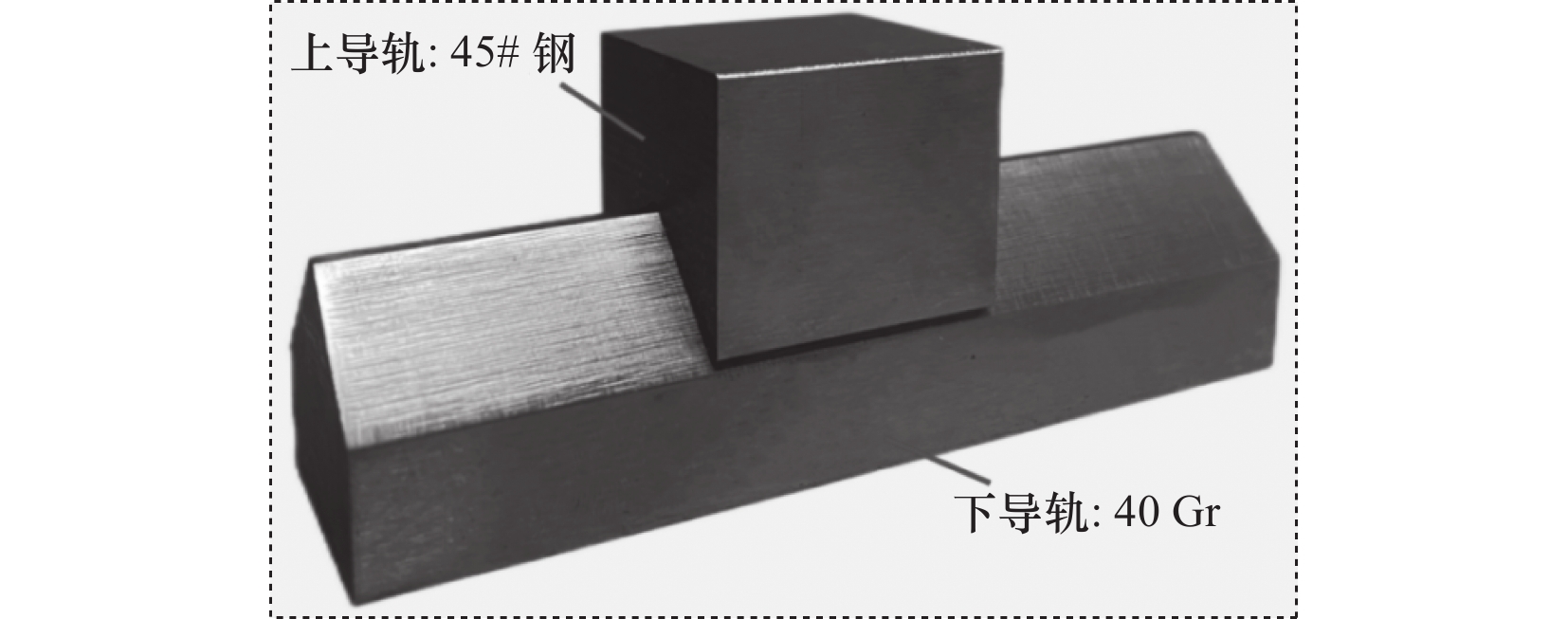

摘要: V型滑动导轨副具有低成本、良好的承载能力和导向性等优点,至今仍应用于很多机械设备中,但同时也存在着摩擦系数大、易磨损和低速稳定性差等缺点。为提高V型滑动导轨副的摩擦学性能,利用激光表面织构化技术分别在导轨的接触面上设计并制备直线和椭圆微织构。通过不同仿真软件对激光制备出的微织构是否产生流体动压效应进行验证,分析微织构对导轨接触面的接触应力的影响。利用自制往复滑动导轨试验平台在混合润滑条件下测试了不同类型织构化导轨副的摩擦磨损性能。结果表明,织构化导轨副均可以产生流体动压效应,且椭圆微织构可以产生更大的流体动压效应。此外,椭圆微织构仅位于下导轨表面可以较大程度降低其接触应力。因此,当椭圆微织构位于下导轨表面时减摩效果最好,具有最低的平均摩擦系数,与无织构导轨副相比下降了31.7%。Abstract: V-shaped sliding guideways are still used in many mechanical equipments due to their advantages of low cost, good load-bearing capacity, and good guidance. However, the guideways also have disadvantages such as high friction coefficient, high wear rate, and poor low-speed stability. To enhance the tribological performance of V-shaped sliding guideways, laser surface texturing technology was used to design and prepare linear and elliptical micro-textures on the contact surfaces of the guideways. Through different simulation software, it was verified that micro-textures can generate hydrodynamic action, and the influence of micro-textures on the contact stress of the guideway contact surface was analyzed. The friction and wear properties of different types of textured guideways were tested by a self-made reciprocating sliding guideway test platform under mixed lubrication condition. The results indicate that textured guideways can generate hydrodynamic action, and elliptical micro-textures can generate larger hydrodynamic action. In addition, the elliptical micro-textures located only on the surface of the lower guideway can significantly reduce its contact stress. Therefore, when the elliptical micro-textures are located on the surface of the lower guideway, the friction reduction effect is the best, with the lowest average friction coefficient, which is reduced by 31.7% compared to the guideways without textures.

-

Key words:

- V-shaped sliding guideways /

- micro-textures /

- hydrodynamic action /

- contact stress

-

表 1 导轨材料化学性质

材料 化学成分占比/(%) C Si Mn Cr S P 45#钢 0.42~0.50 0.17~0.37 0.50~0.80 ≤0.0035 ≤0.003 5 ≤0.003 5 40铬 0.38~0.43 0.17~0.37 0.50~0.80 0.80~1.00 ≤0.003 5 ≤0.003 5 表 2 润滑油参数

润滑油牌号 粘度指数 倾点/℃ 闪点/℃ 40 ℃运动粘度/(mm2$ / $s) L-G 46 46 −20 218 41.4~50.6 表 3 V型滑动导轨副表面接触应力的平均值

上导轨接触面接触

应力的平均值/MPa下导轨接触面接触

应力的平均值/MPaW-NS 2.137 0.206 U-ZS 2.125 — U-TS 1.808 — D-ZS — 0.128 D-TS — 0.012 UD-ZS 2.425 0.389 UD-TS 1.980 5.648×10−8 -

[1] Tarng Y S,Cheng H E. An investigation of stick-slip friction on the contouring accuracy of CNC machine tools[J]. Machine Tools and Manufacture,1995,35(4):565-576. doi: 10.1016/0890-6955(94)P4350-4 [2] Chen J S,Kuo Y H,Hsu W Y. The influence of friction on contouring accuracy of a Cartesian guided tripod machine tool[J]. Advanced Manufacturing Technology,2006,30:470-478. doi: 10.1007/s00170-005-0088-8 [3] Adawy A,Abdel-Fattah W I. An efficient biomimetic coating methodology for a prosthetic alloy[J]. Materials Science and Engineering:C,2013,33(3):1813-1818. [4] Yan X X,Cao W,Li H H. Biomedical alloys and physical surface modifications:a mini-review[J]. Materials,2021,15(1):66. doi: 10.3390/ma15010066 [5] Obilor A F,Pacella M,Wilson A,et al. Micro-texturing of polymer surfaces using lasers:A review[J]. Advanced Manufacturing Technology,2022,120(1-2):103-135. doi: 10.1007/s00170-022-08731-1 [6] Patel D,Jain V K,Ramkumar J. Micro texturing on metallic surfaces:State of the art[J]. Mechanical Engineers,Part B:2018,232(6):941-964. [7] Koshy P,Tovey J. Performance of electrical discharge textured cutting tools[J]. CIRP Annals,2011,60(1):153-156. doi: 10.1016/j.cirp.2011.03.104 [8] Bhattacharyya B,Mitra S,Boro A K. Electrochemical machining:new possibilities for micromachining[J]. Robotics and Computer-Integrated Manufacturing,2002,18(3-4):283-289. doi: 10.1016/S0736-5845(02)00019-4 [9] Meijer J. Laser beam machining (LBM),state of the art and new opportunities[J]. Materials Processing Technology,2004,149(1-3):2-17. doi: 10.1016/j.jmatprotec.2004.02.003 [10] Zhou X W,Wang X Z . Application of the laser processing technology in industry[J]. Journal of Zhongzhou University,2005. [11] Marian V G,Gabriel D,Knoll G,et al. Theoretical and experimental analysis of a laser textured thrust bearing[J]. Tribology Letters,2011,44:335-343. doi: 10.1007/s11249-011-9857-8 [12] Sinanoğlu C,Nair F,Karamış M B. Effects of shaft surface texture on journal bearing pressure distribution[J]. Materials Processing Technology,2005,168(2):344-353. doi: 10.1016/j.jmatprotec.2005.02.252 [13] Fowell M T,Medina S,Olver A V,et al. Parametric study of texturing in convergent bearings[J]. Tribology International,2012,52:7-16. doi: 10.1016/j.triboint.2012.02.013 [14] Ge D L,Deng J X,Duan R X,et al. Effect of micro-textures on cutting fluid lubrication of cemented carbide tools[J]. Advanced Manufacturing Technology,2019,103:3887-3899. doi: 10.1007/s00170-019-03763-6 [15] Enomoto T,Sugihara T. Improving anti-adhesive properties of cutting tool surfaces by nano-/micro-textures[J]. CIRP Annals,2010,59(1):597-600. doi: 10.1016/j.cirp.2010.03.130 [16] Ryk G,Etsion I. Testing piston rings with partial laser surface texturing for friction reduction[J]. Wear,2006,261(7-8):792-796. doi: 10.1016/j.wear.2006.01.031 [17] Nakano M ,Korenaga A ,Korenaga A ,et al. Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions[J]. Tribology Letters,2007,28(2):131-137. [18] Pang Z B,Zhou H,Xie G F,et al. Effect of bionic coupling units׳ forms on wear resistance of gray cast iron under dry linear reciprocating sliding condition[J]. Optics & Laser Technology,2015,70:89-93. [19] Wang H ,Xie X ,Hua X J ,et al. The effect of laser surface texturing to inhibit stick-slip phenomenon in sliding contact[J]. Advances in Mechanical Engineering,2019,11(9):1-10. [20] Zhang H F ,Zhou T ,Zhou H ,et al. Effects of different bionic units coupling on the sliding wear of gray cast iron[J]. Surface and Coatings Technology,2017,309:96-105. [21] Groper D,Wang L,Harvey T J. Hydrodynamic lubrication of textured surfaces:A review of modeling techniques and key findings[J]. Tribology International,2016,94:509-529. doi: 10.1016/j.triboint.2015.10.009 [22] Hamilton D B,Walowit J A,Allen C M. A theory of lubrication by microirregularities[J]. Journal of Basic Engineering,1966,88(1):177. doi: 10.1115/1.3645799 [23] Wang X,Kato K,Adachi K,et al. The effect of laser texturing of SiC surface on the critical load for the transition of water lubrication mode from hydrodynamic to mixed[J]. Tribology International,2001,34(10):703-711. doi: 10.1016/S0301-679X(01)00063-9 [24] Checo H M,Jaramillo A,Jai M,et al. Texture-induced cavitation bubbles and friction reduction in the Elrod–Adams model[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology,2015,229(4):478-492. [25] Nie X,Meletis E I,Jiang J C,et al. Abrasive wear/corrosion properties and TEM analysis of Al2O3 coatings fabricated using plasma electrolysis[J]. Surface and Coatings Technology,2002,149(2-3):245-251. doi: 10.1016/S0257-8972(01)01453-0 [26] Trezona R I,Allsopp D N,Hutchings I M. Transitions between two-body and three-body abrasive wear:Influence of test conditions in the microscale abrasive wear test[J]. Wear,1999,225:205-214. -

下载:

下载: