Research progress of diamond wire saw electrical discharge composite sawing of hard-brittle semiconductors

-

摘要: 太阳能光伏产业和电子工业的迅速发展对使用的晶体硅等硬脆半导体材料的切割提出了更高的要求。为了进一步提高硬脆半导体的切割加工质量和生产效率、降低生产成本,金刚石线锯电火花复合切割技术开始被应用到硬脆半导体的切割中。文章从加工原理、工艺性能和影响因素等方面综述了金刚石线锯电火花复合切割硬脆半导体材料的研究现状,并对后续的发展和研究方向进行了展望。

-

关键词:

- 金刚石线锯电火花复合切割 /

- 硬脆半导体 /

- 加工机理

Abstract: The rapid development of the solar photovoltaic and the electronics industry has put forward higher requirements for the cutting of hard-brittle semiconductor materials such as crystalline silicon. To further improve the cutting quality and production efficiency of hard and brittle semiconductors and reduce the production cost, diamond wire saw electrical discharge composite sawing has been applied to hard and brittle semiconductor cutting. In this paper, the research progress of this composite sawing technology of hard and brittle semiconductor materials is reviewed from the processing principle, process performance and influencing factors, and the future development and research direction are prospected. -

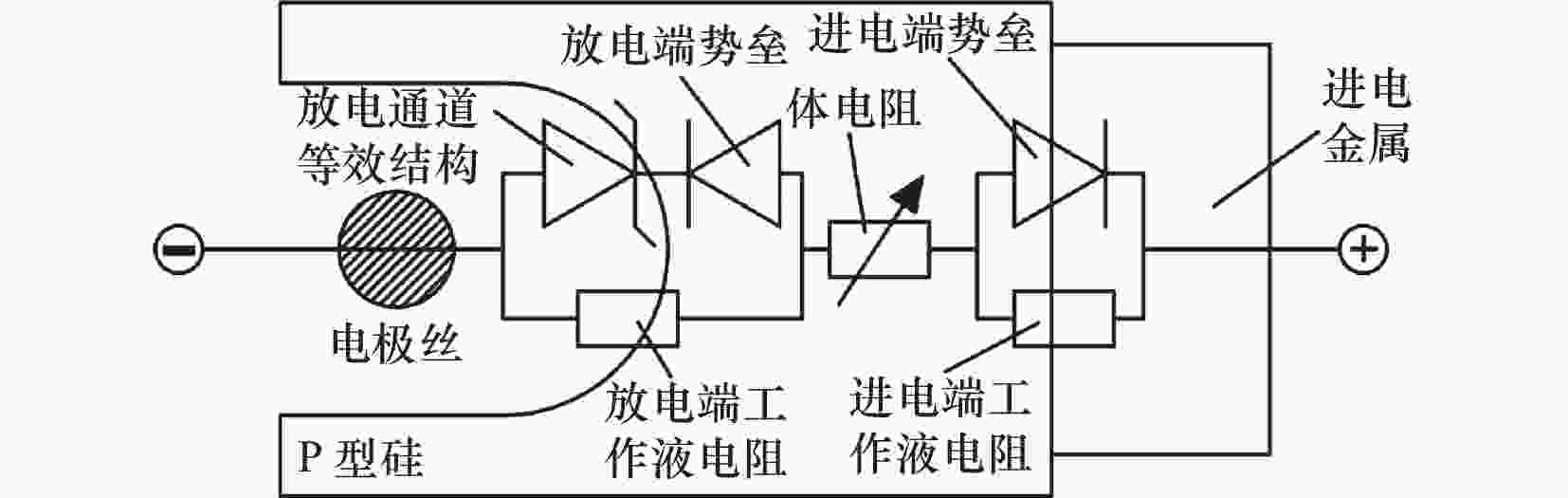

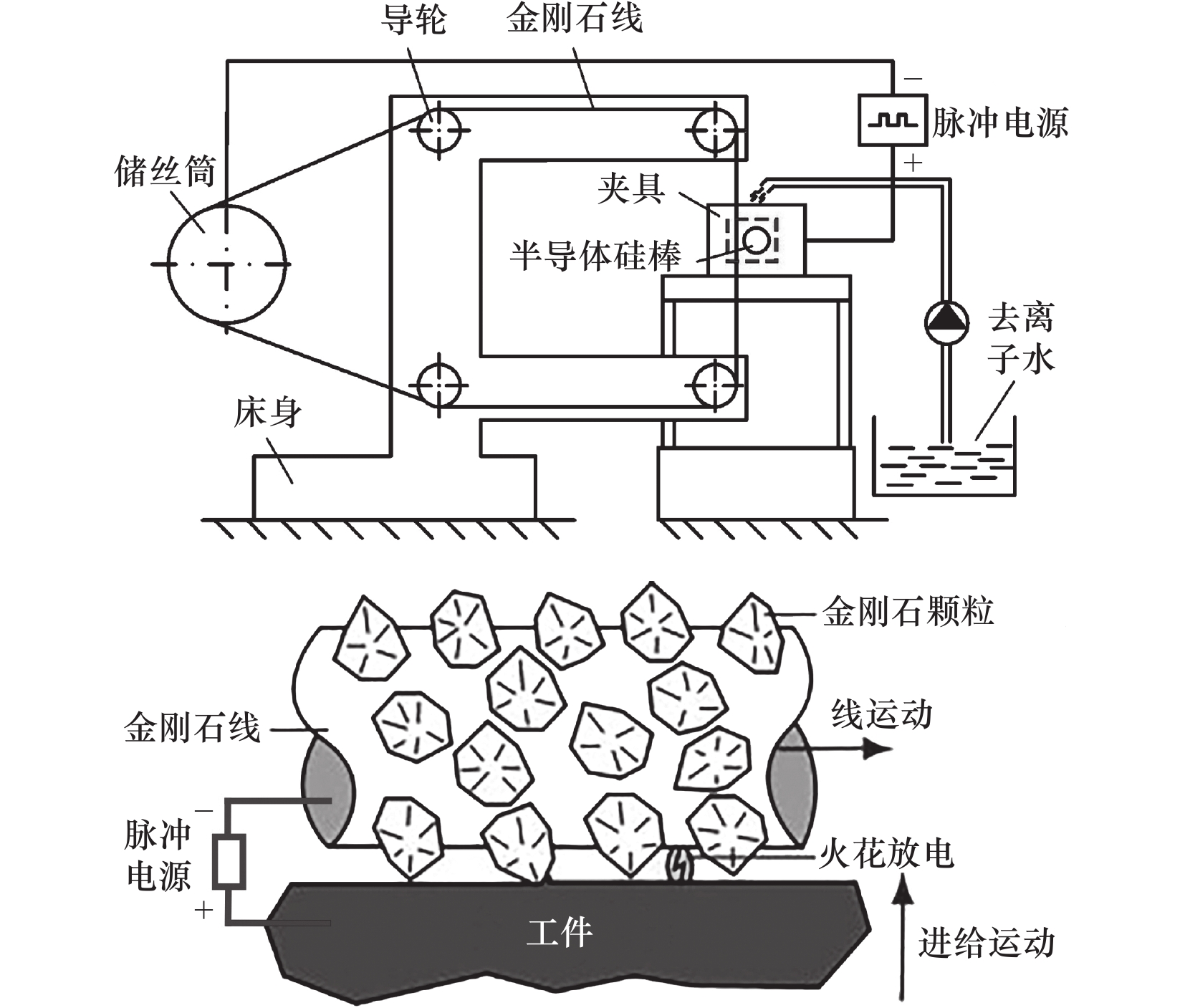

图 2 P型晶体硅正极性放电等效电路[9]

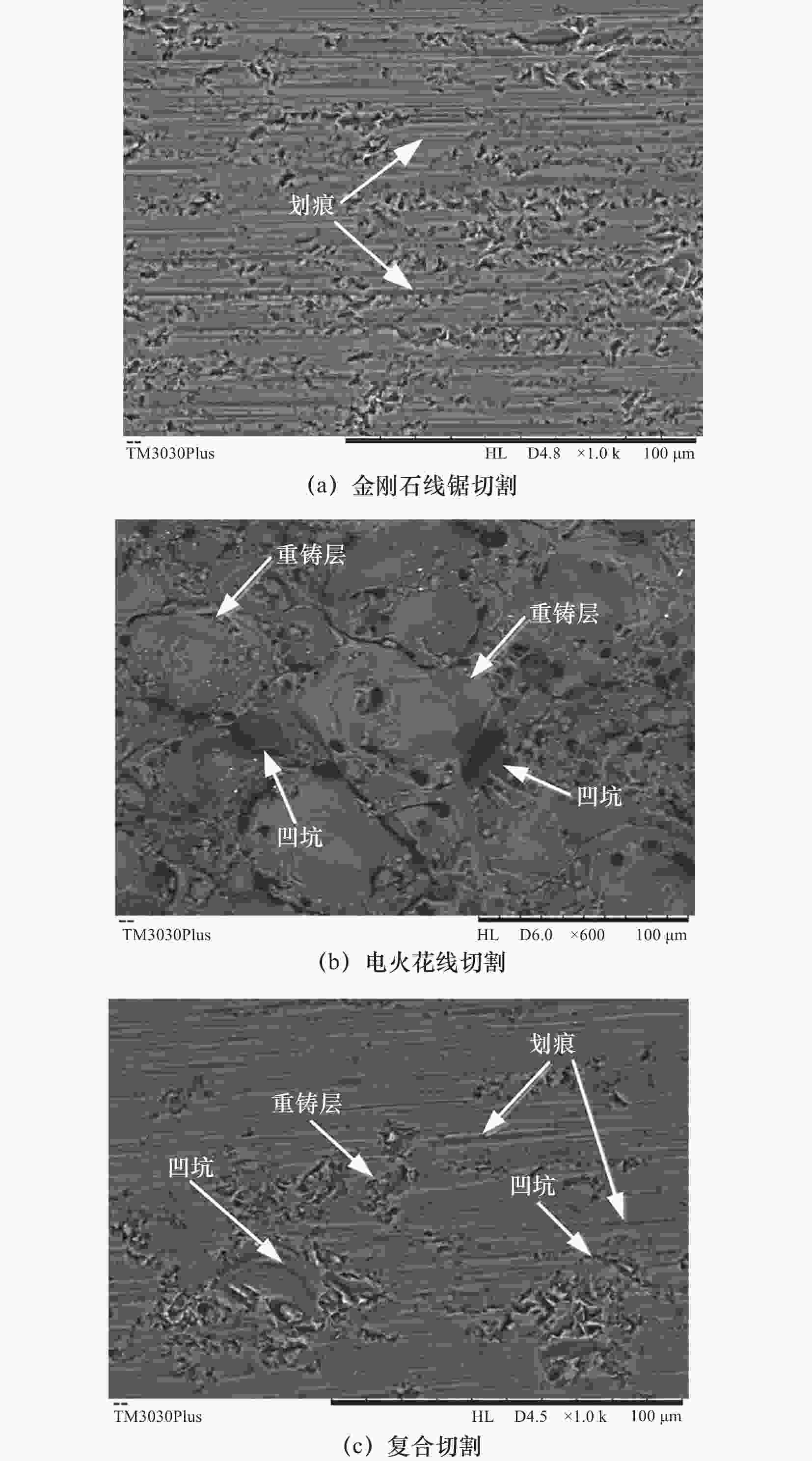

图 3 复合切割加工状态[8]

图 4 连续脉冲信号单个脉冲周期内单颗金刚石磨粒去除材料示意图[19]

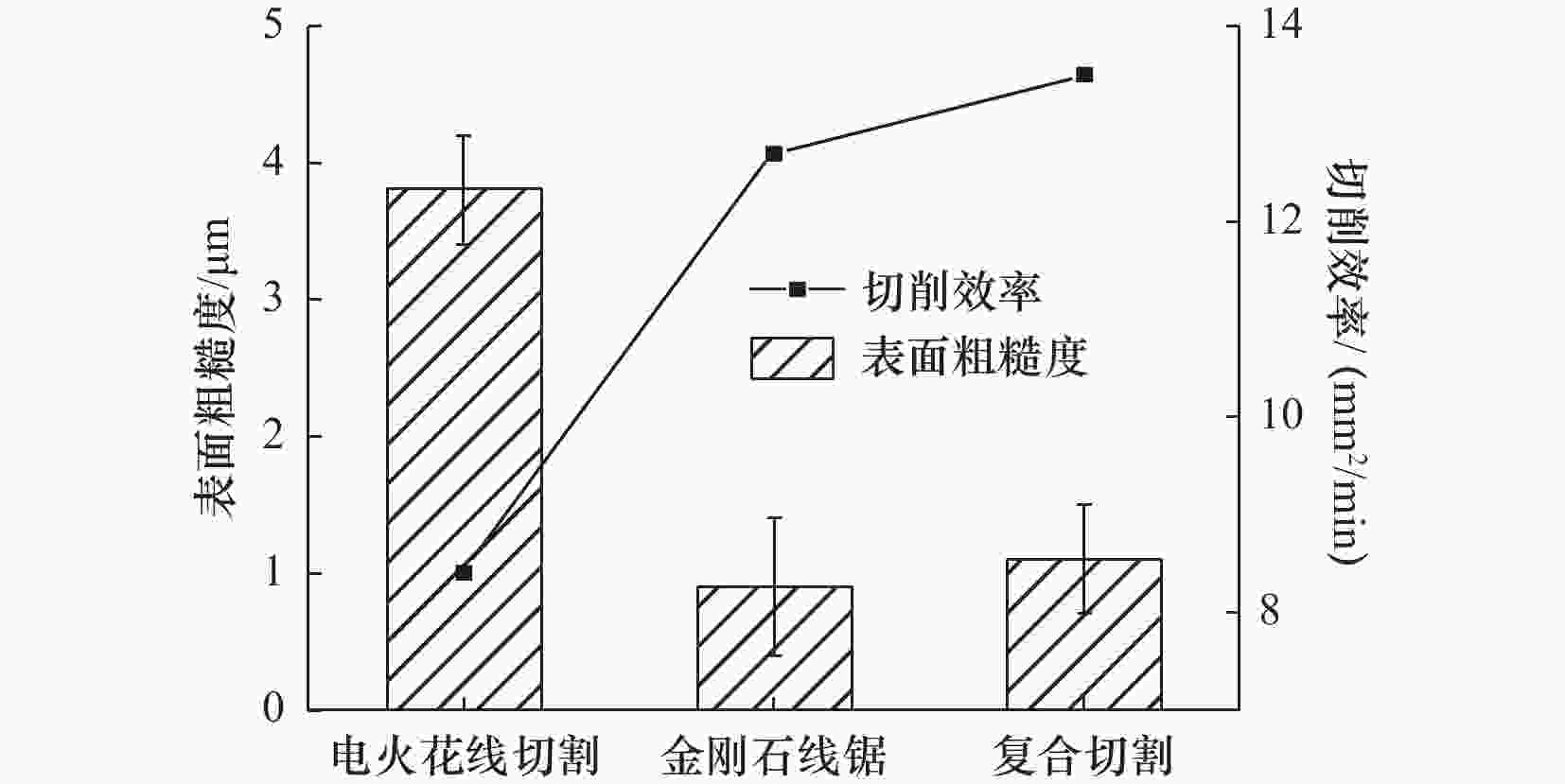

图 5 3种加工方法的切削效率与表面粗糙度对比[10]

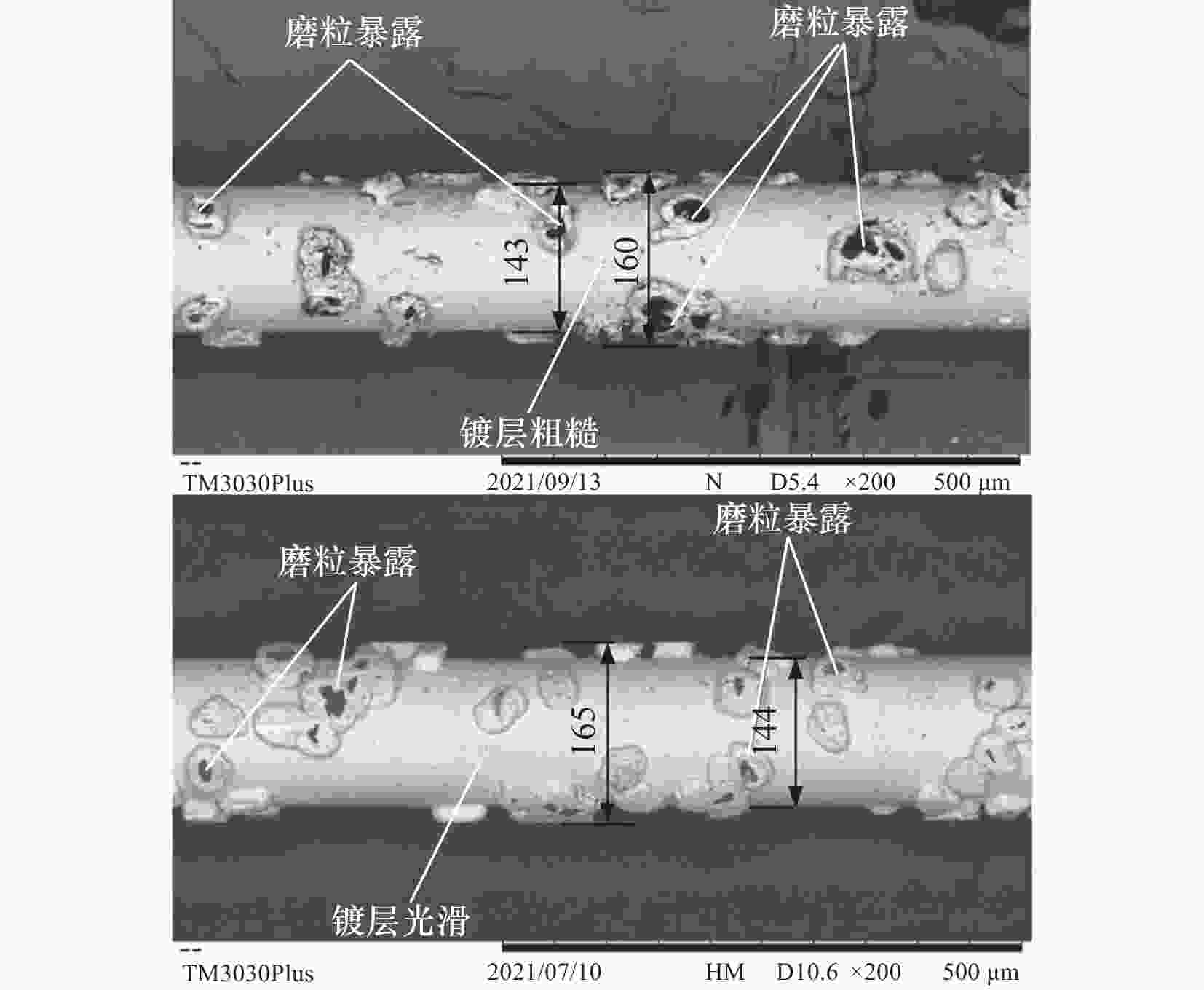

图 7 复合切割(上)与金刚石线锯切割(下)在相同锯切量下的线材磨损[16]

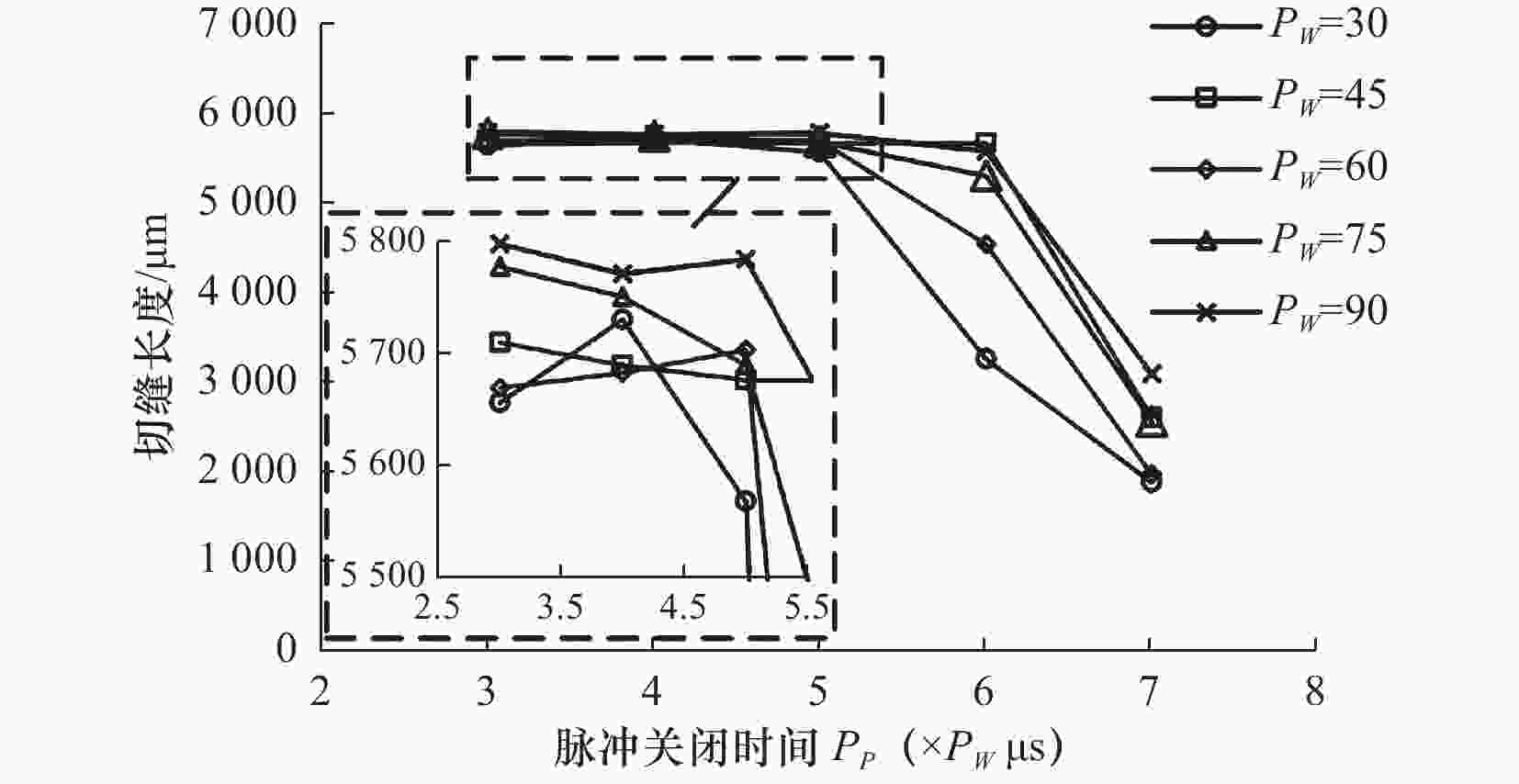

图 8 脉冲开启时间PW和脉冲关闭时间PP对切缝长度的影响[17]

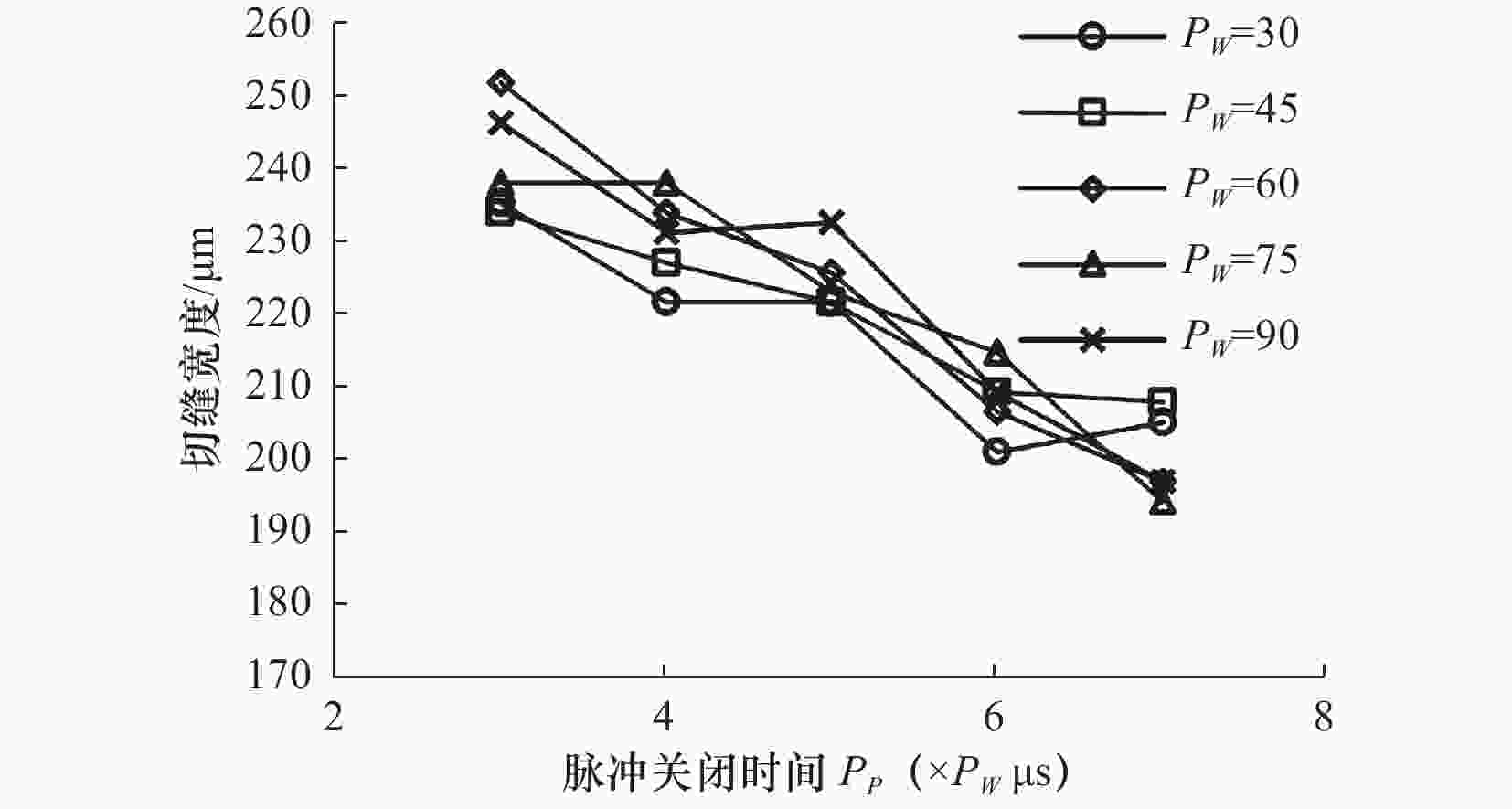

图 9 脉冲开启时间PW和脉冲关闭时间PP对切缝宽度的影响[17]

图 10 进给速度对表面损伤层厚度的影响[17]

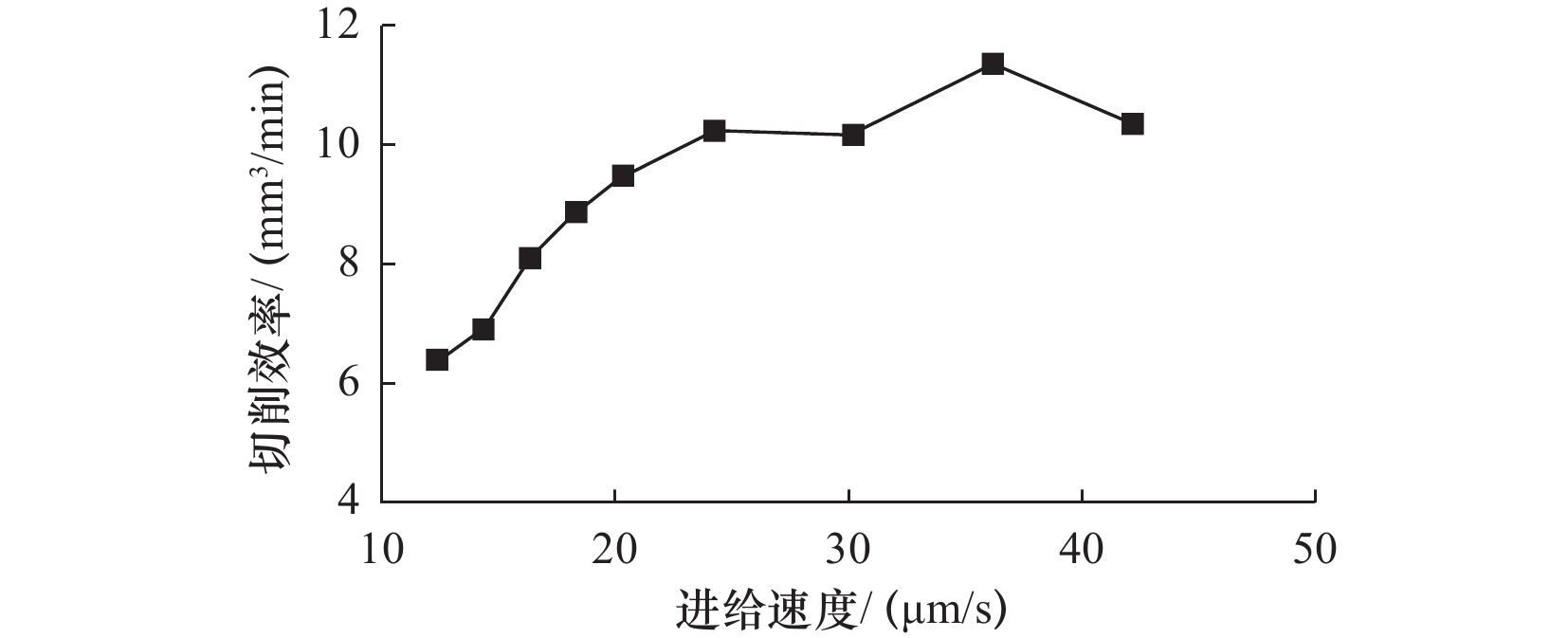

图 11 进给速度对切削效率的影响[17]

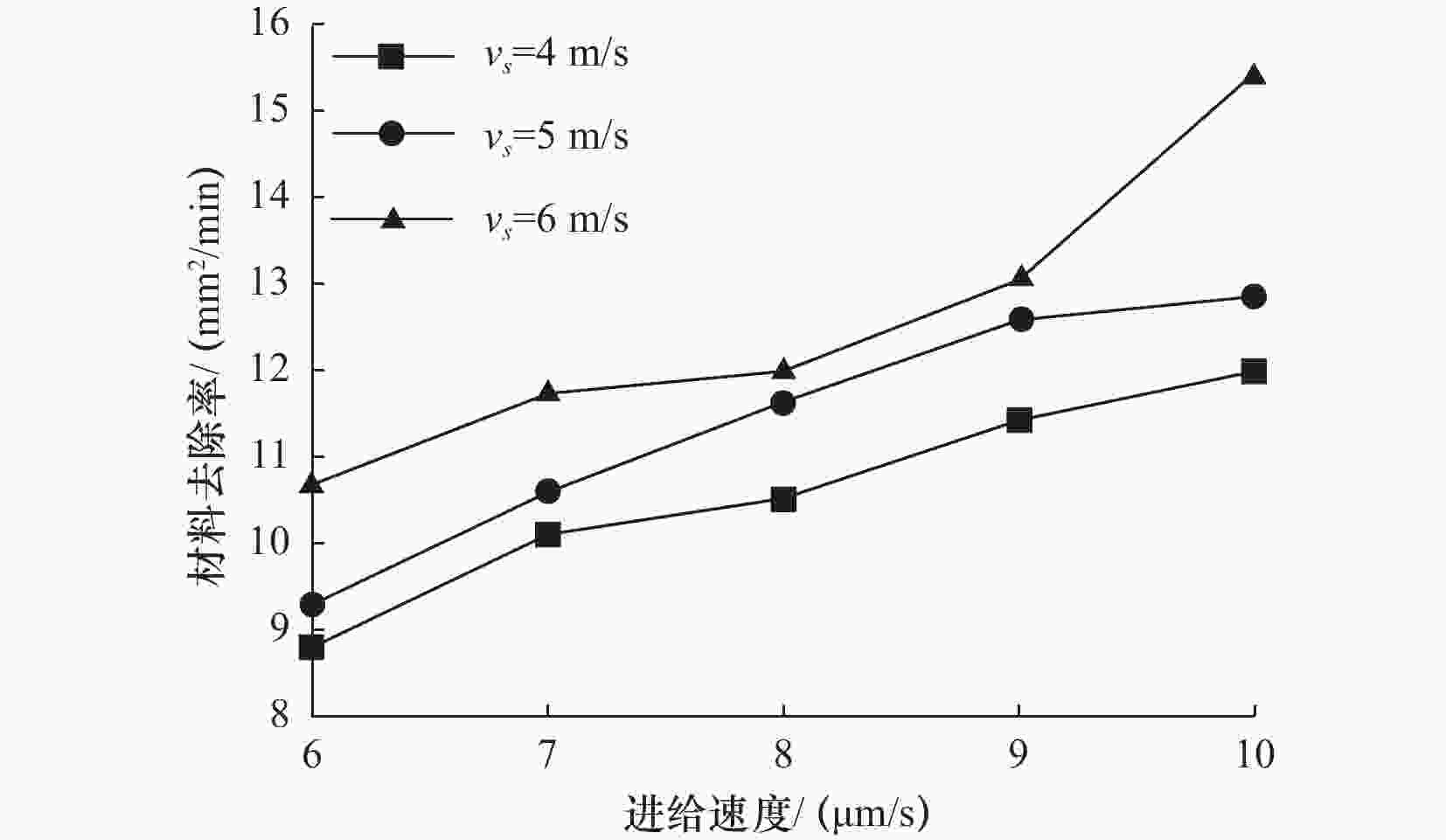

图 12 进给速度与线锯速度对材料去除率的影响[19]

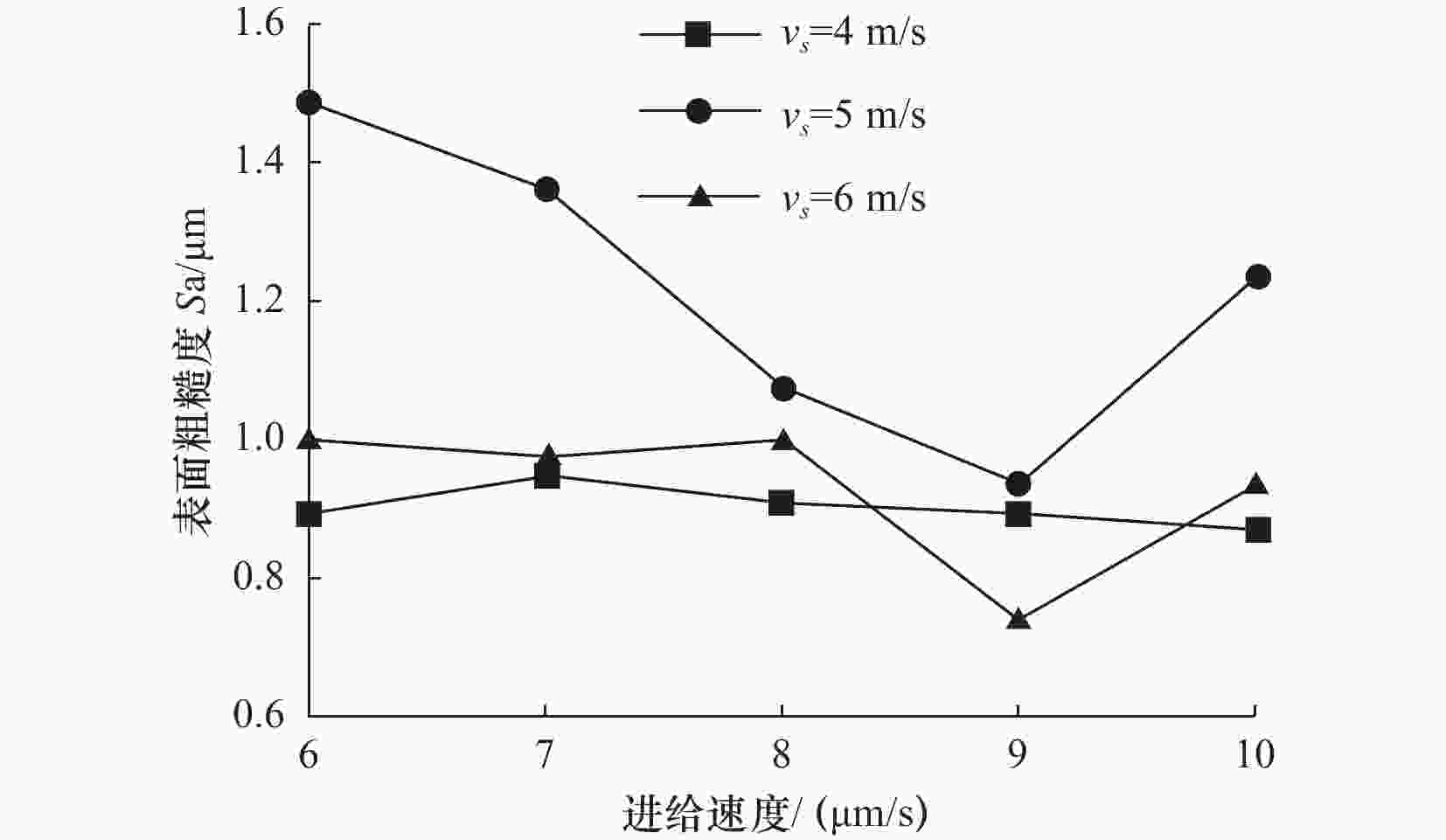

图 13 进给速度与线锯速度对表面粗糙度的影响[19]

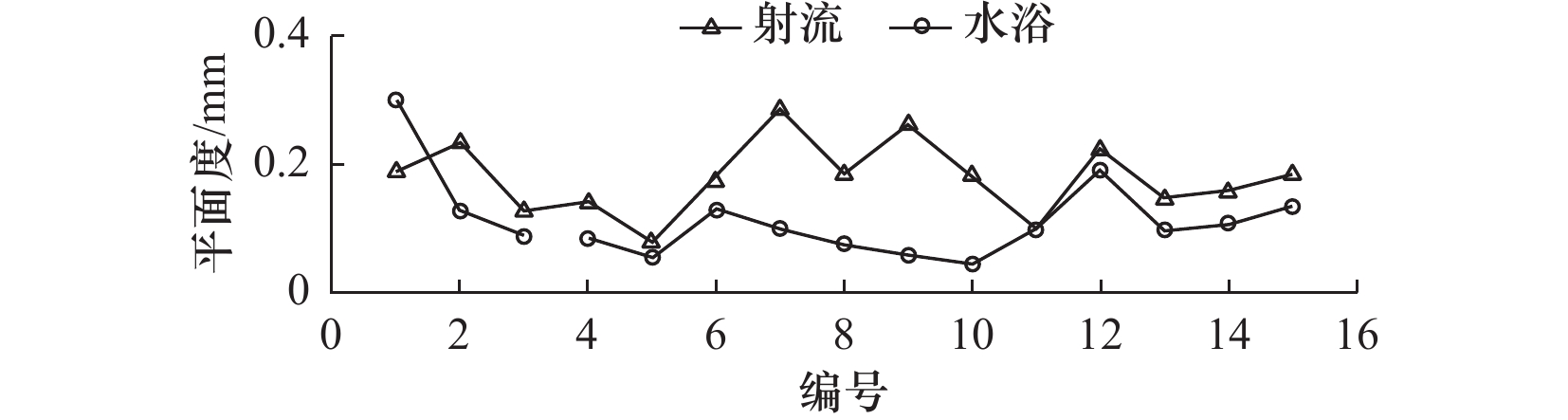

图 14 不同冷却下复合切割的加工精度(平面度)[16]

-

[1] Yu X G,Wang P,Li X Q,et al. Thin czochralski silicon solar cells based on diamond wire sawing technology[J]. Solar Energy Materials and Solar Cells,2012,98:337-342. doi: 10.1016/j.solmat.2011.11.028 [2] 李升,高玉飞. 电镀金刚石线表面磨粒密度对锯切性能影响分析[J]. 制造技术与机床,2020(6):104-107. doi: 10.19287/j.cnki.1005-2402.2020.06.018 [3] 鲍官培,汪炜,曹祥威. 金刚石线锯电解磨削切割多晶硅片的试验研究[J]. 电加工与模具,2016(6):41-48. doi: 10.3969/j.issn.1009-279X.2016.06.009 [4] Bao G P,Wang W,Zhang L. Mechanism of material removal in abrasive electrochemical multi-wire sawing of multi-crystalline silicon ingots into wafers[J]. The International Journal of Advanced Manufacturing Technology,2017,91:383-388. doi: 10.1007/s00170-016-9718-6 [5] Bao G P,Huang C,Zhang Y J,et al. Experimental study on surface integrity of solar cell silicon wafers sliced by electrochemical multi-wire saw[J]. Micromachines,2022,13(9):1469-1479. doi: 10.3390/mi13091469 [6] 袁日灿,单翔,金亦富. 超声辅助金刚石线锯切割硬脆材料的研究[J]. 机械工程与自动化,2018(1):136-137,140. doi: 10.3969/j.issn.1672-6413.2018.01.058 [7] 李德蔺. 超声辅助金刚石线锯切割单晶硅复合加工机理及试验研究[D]. 上海:上海理工大学,2019. [8] Zhou W W,Liu Z D,Zhang B,et al. Experimental research on semiconductor shaping by abrasive-spark hybrid machining[J]. The International Journal of Advanced Manufacturing Technology,2018,94:2209-2216. doi: 10.1007/s00170-017-1013-7 [9] 周威威. 金刚石线锯电火花复合形状切割工艺及弯丝控制研究[D]. 南京:南京航天航空大学,2018. [10] Wu X Y,Li S J. Experimental investigations of a hybrid machining combining wire electrical discharge machining (WEDM) and fixed abrasive wire saw[J]. The International Journal of Advanced Manufacturing Technology,2018,95:2613-2623. doi: 10.1007/s00170-017-1357-z [11] Wang J,Sun L,Jia Z X. Research on electrochemical discharge-assisted diamond wire cutting of insulating ceramics[J]. The International Journal of Advanced Manufacturing Technology,2017,93:3043-3051. doi: 10.1007/s00170-017-0751-x [12] Furutani K,Tomoto M. Performance of wire-sawing of glass assisted by electro-chemical discharge[J]. Key Engineering Materials,2012,523-524:299-304. doi: 10.4028/www.scientific.net/KEM.523-524.299 [13] Wang J,Fu C,Jia Z X. Cutting of hard and brittle insulating materials using spark discharge-assisted diamond wire sawing[J]. Journal of Materials Processing Technology,2018,252:225-232. doi: 10.1016/j.jmatprotec.2017.09.027 [14] Qiu J. Fundamental research on machining performance of diamond wire sawing and diamond wire electrical discharge sawing quartz glass[J]. Ceramics International,2022,48:24332-24345. doi: 10.1016/j.ceramint.2022.04.327 [15] Wang J,Jia Z X,Guo Y B. Shape-cutting of quartz glass by spark discharge-assisted diamond wire sawing[J]. Journal of Manufacturing Processes,2018,34:131-139. doi: 10.1016/j.jmapro.2018.06.001 [16] Qiu J,Li X F,Lv J Z,et al. Surface flatness and roughness of diamond wire electrical discharge sawing mono-crystalline silicon with improved bath cooling[J]. The International Journal of Advanced Manufacturing Technology,2022,120:6251-6267. doi: 10.1007/s00170-022-09155-7 [17] Qiu J,Ge R P. High-performance electrical discharge sawing of hard and brittle monocrystalline silicon by electroplated diamond wire[J]. The International Journal of Advanced Manufacturing Technology,2022,120:2031-2046. doi: 10.1007/s00170-022-08871-4 [18] Qiu J,Lv J Z. Machining accuracy and force characteristic of diamond wire sawing and diamond wire electrical discharge sawing during rip sawing and cross sawing[J]. The International Journal of Advanced Manufacturing Technology,2023,126:697-707. [19] 贾祯,李淑娟,麻高领,等. 单晶硅的磨削辅助电火花线切割机理研究[J]. 中国机械工程,2022,33(20):2459-2167. [20] Menzies I,Koshy P. Assessment of abrasion-assisted material removal in wire EDM[J]. CIRP Annals-Manufacturing Technology,2008,57:195-198. doi: 10.1016/j.cirp.2008.03.135 [21] Pan H J,Liu Z D,Qiu M B,et al. Study on the high efficiency mechanism in WEDM of semiconductor in micro contact condition[J]. Journal of Synthetic Crystals,2013,42(7):1336-1342. -

下载:

下载: