Research on ultrasonic synergistic cleaning of copper electrode cathode titanium plate silicon carbide suspension

-

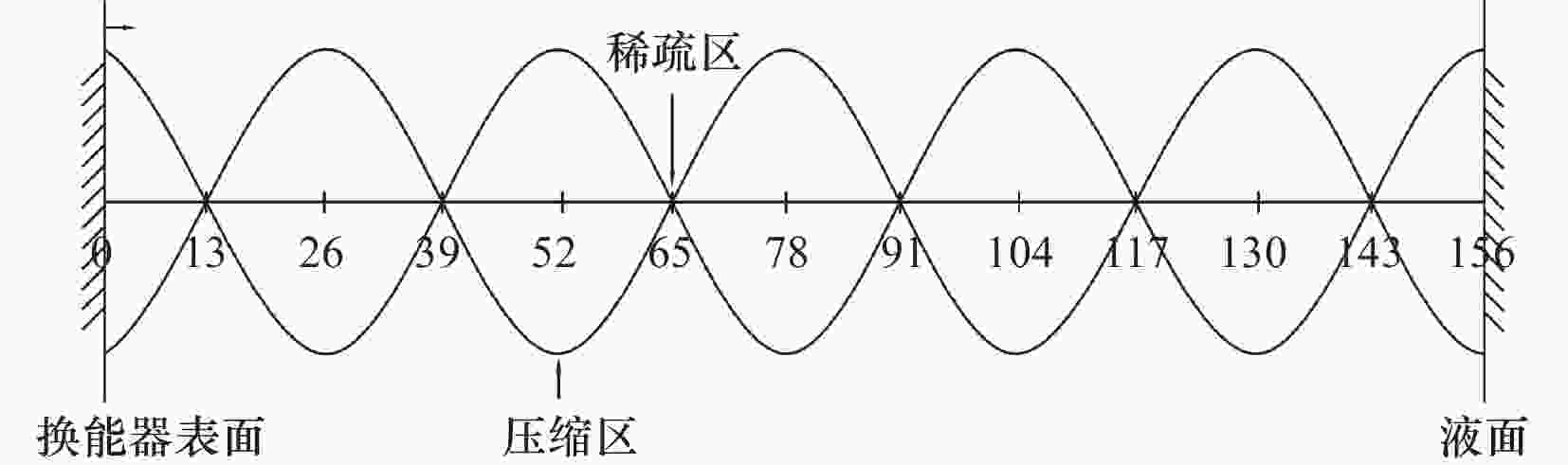

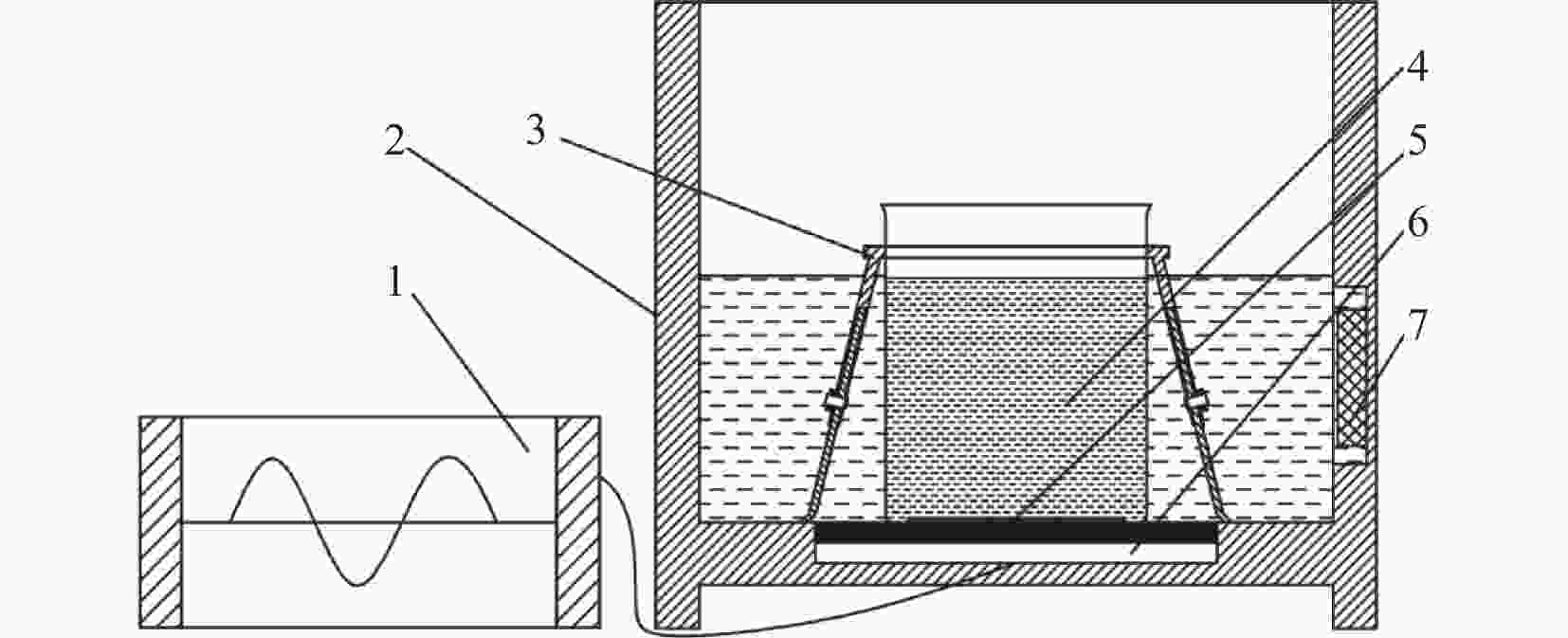

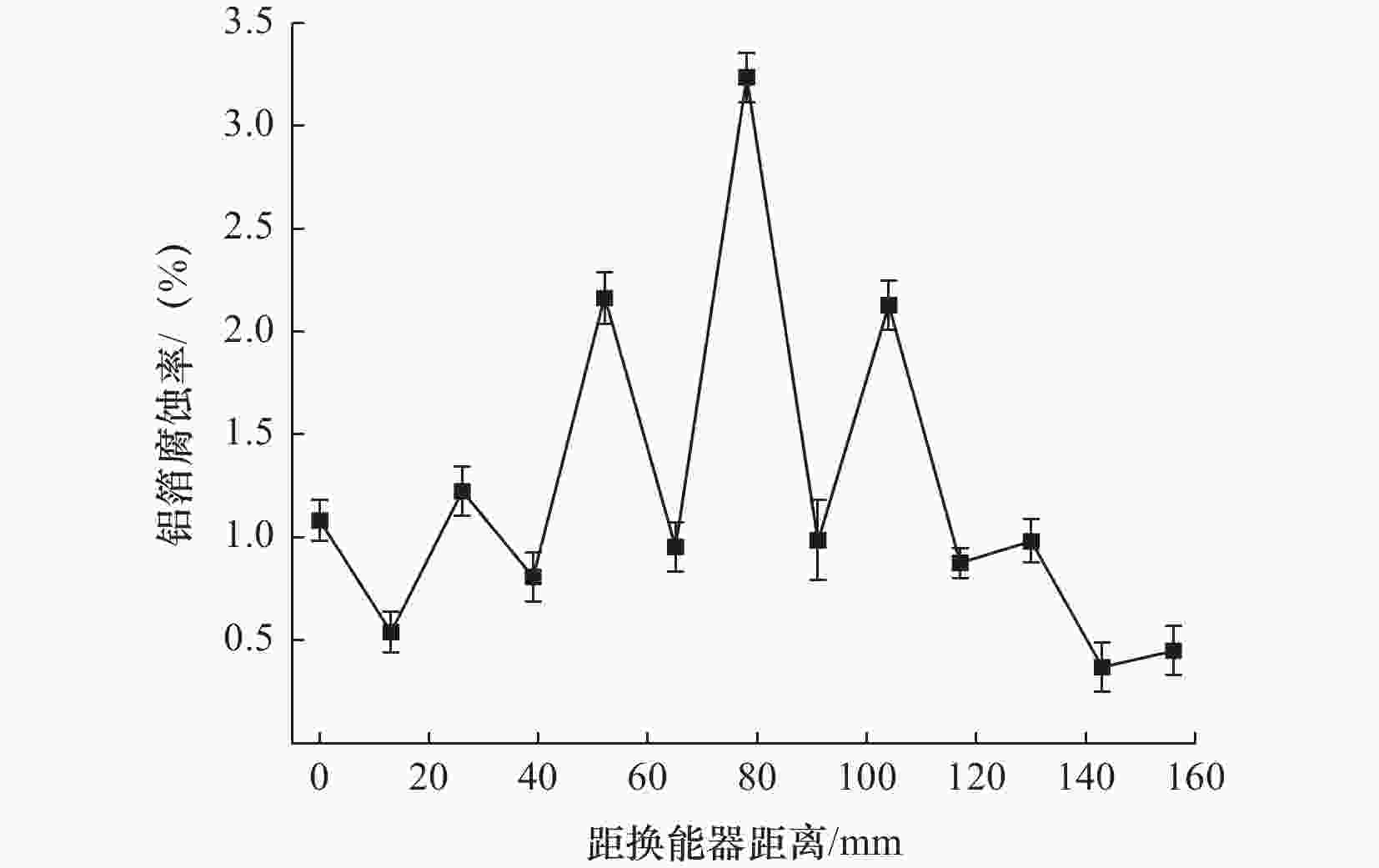

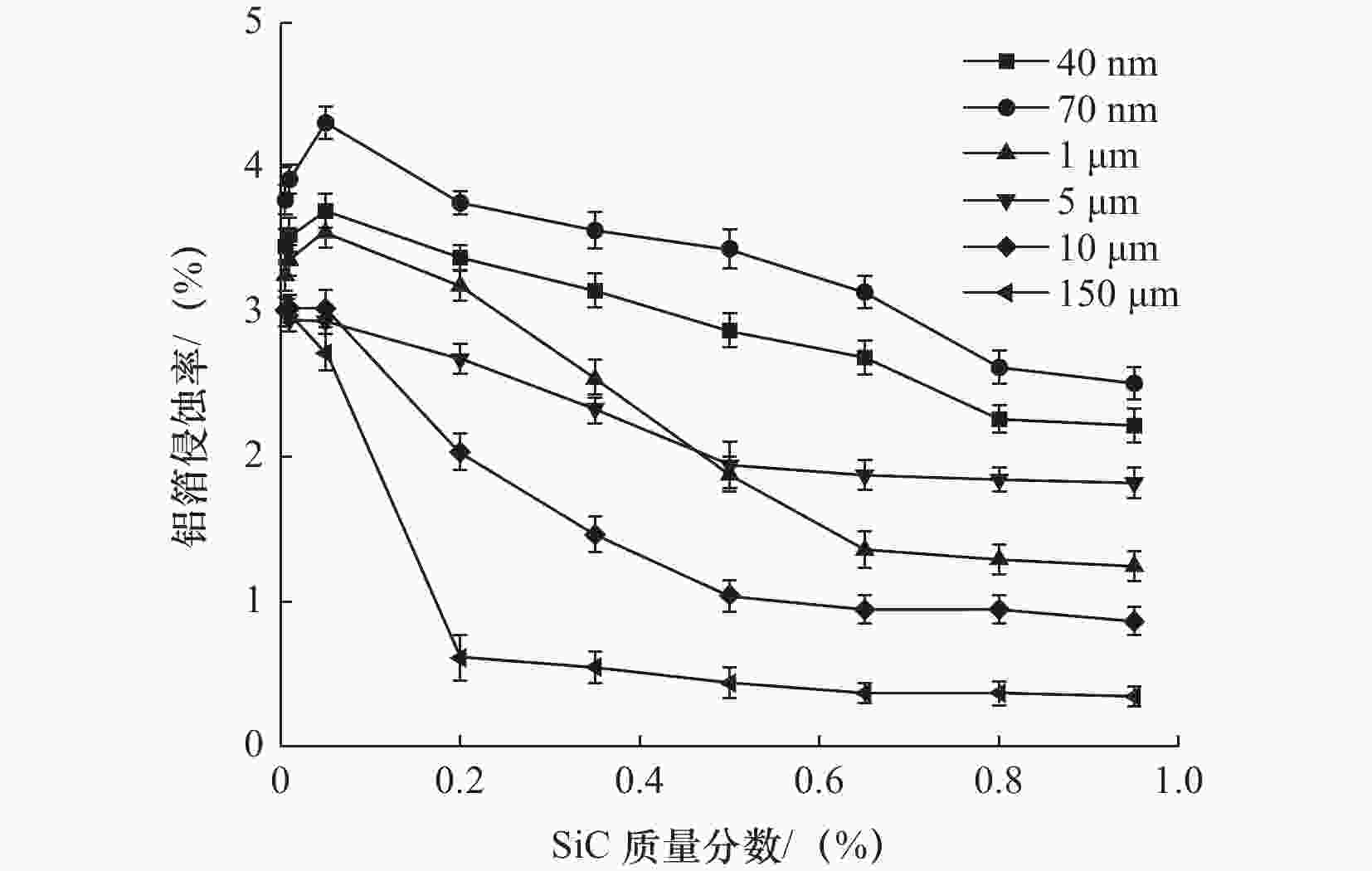

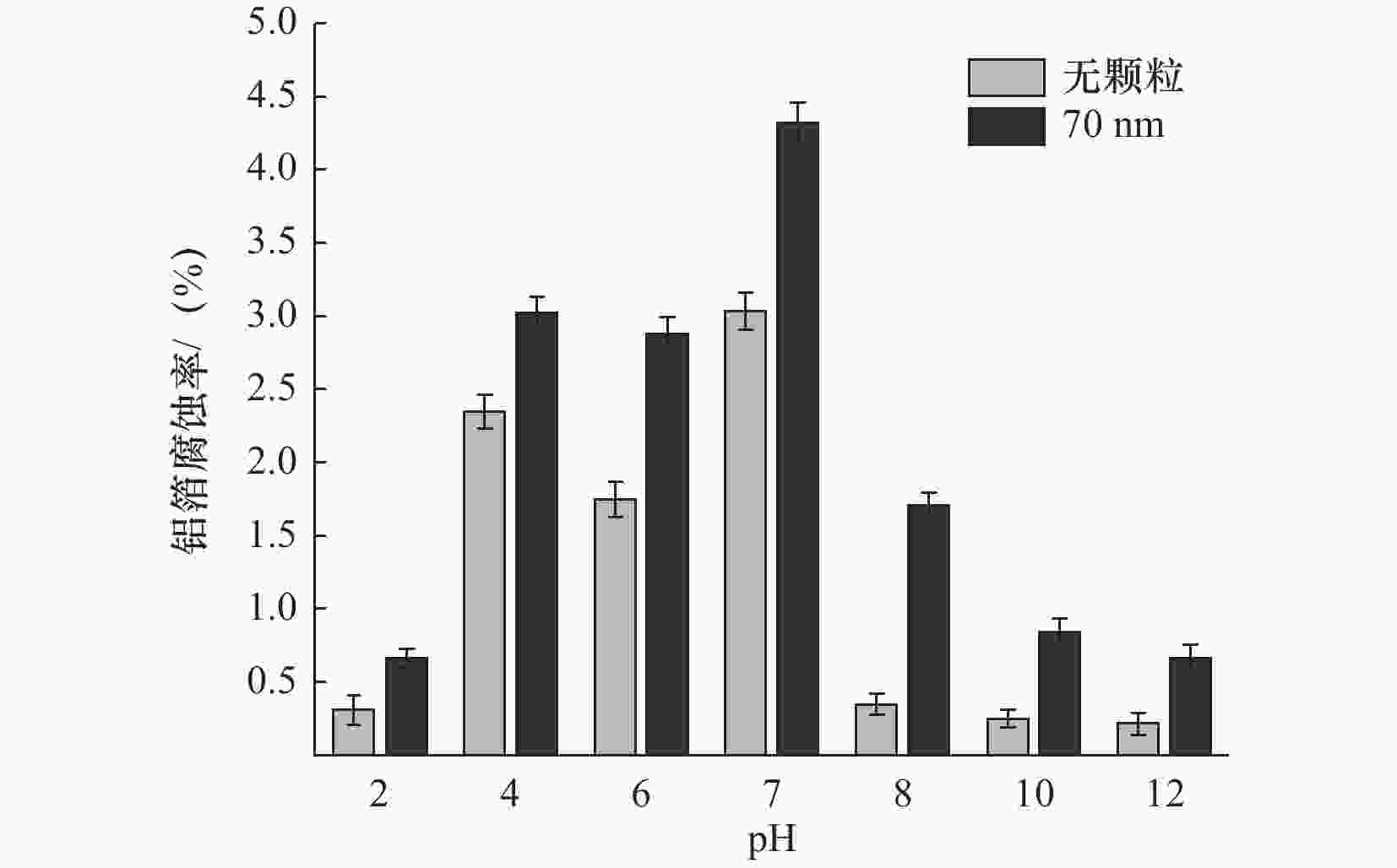

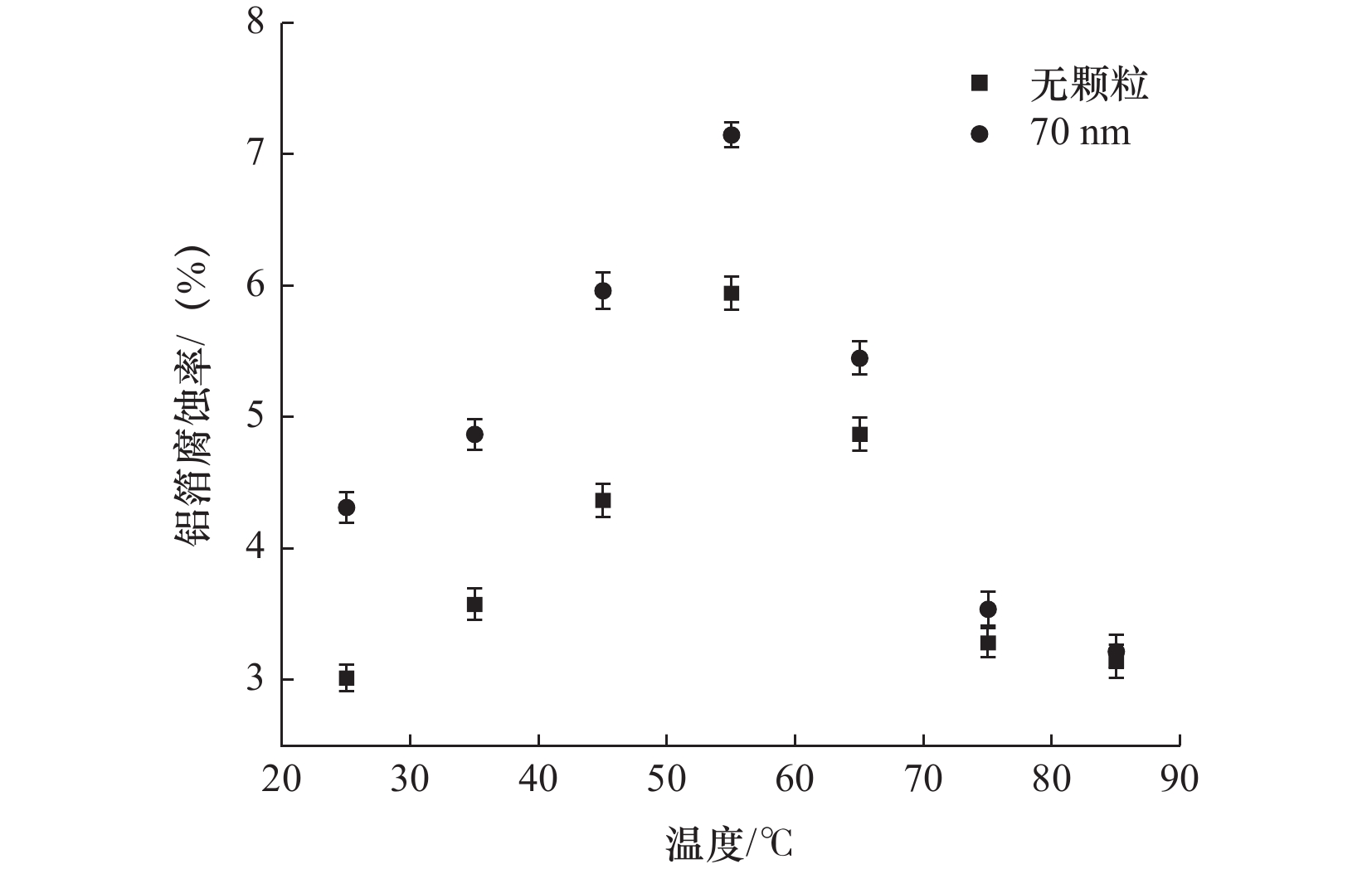

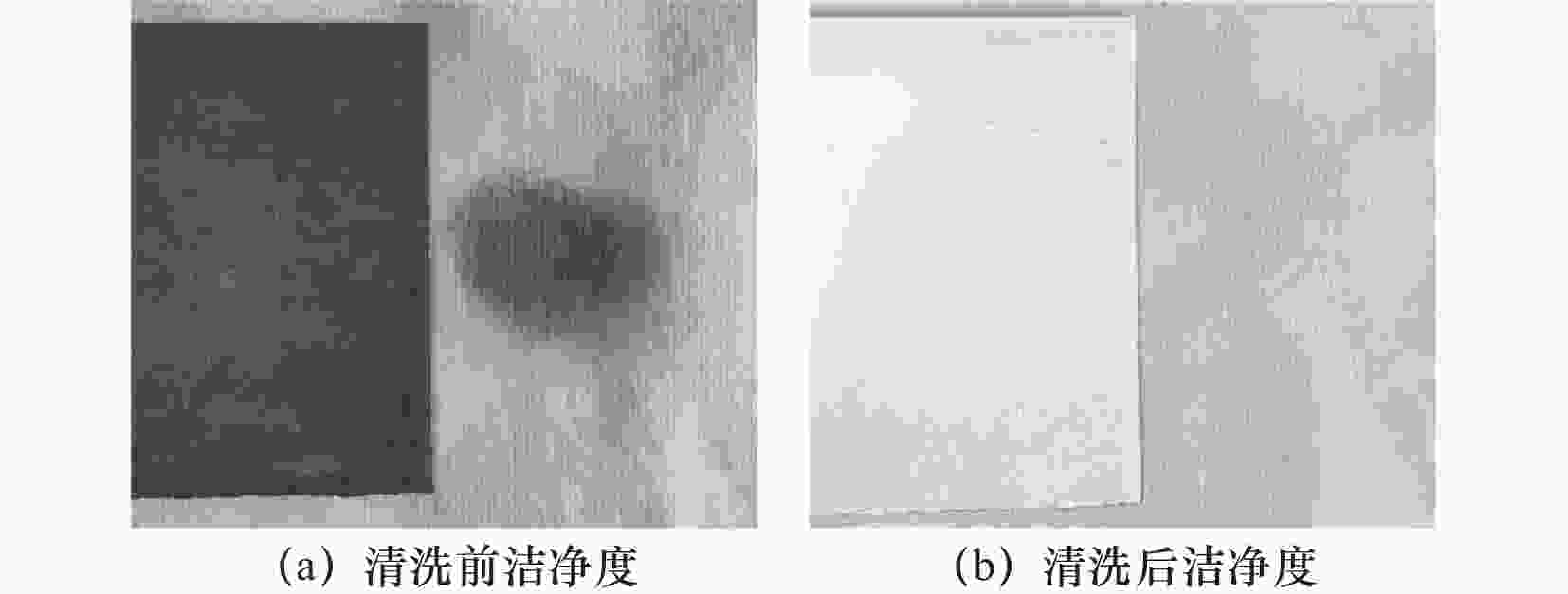

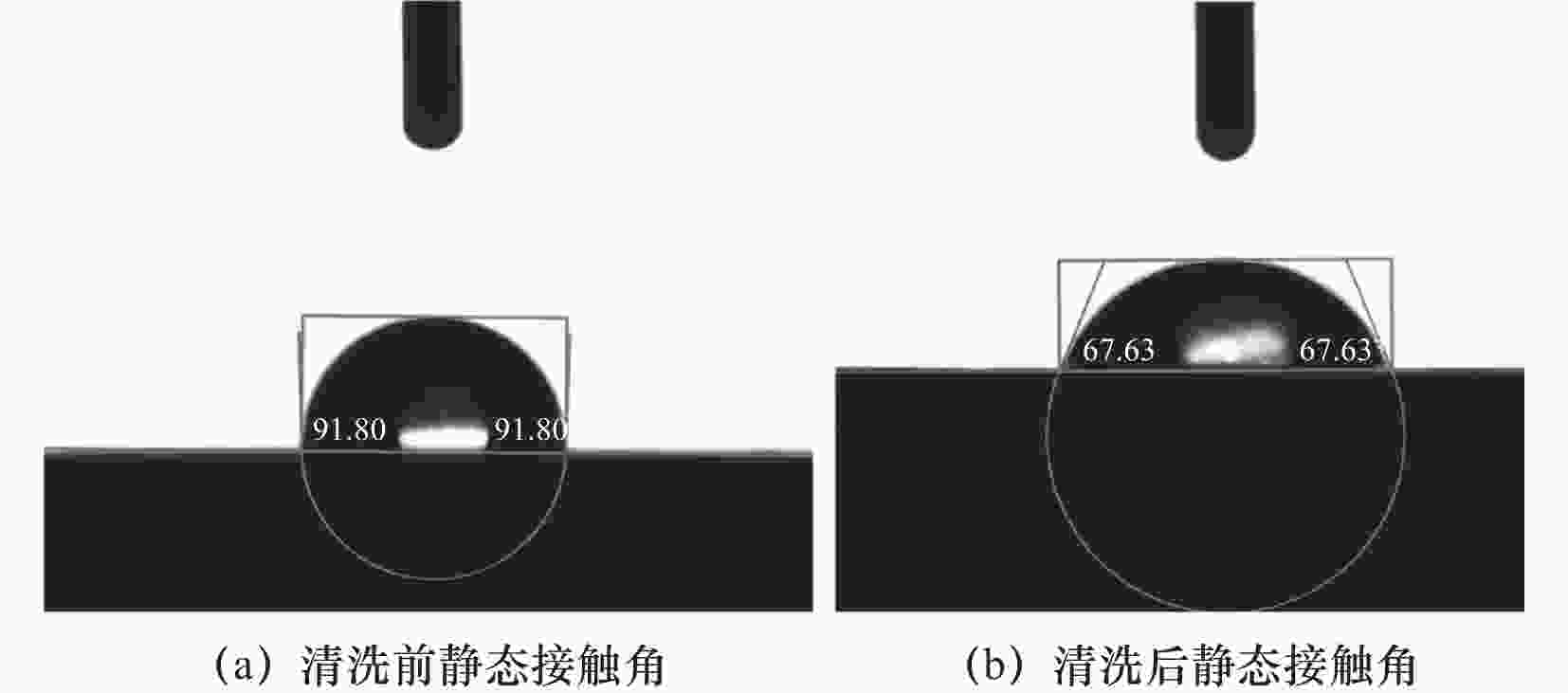

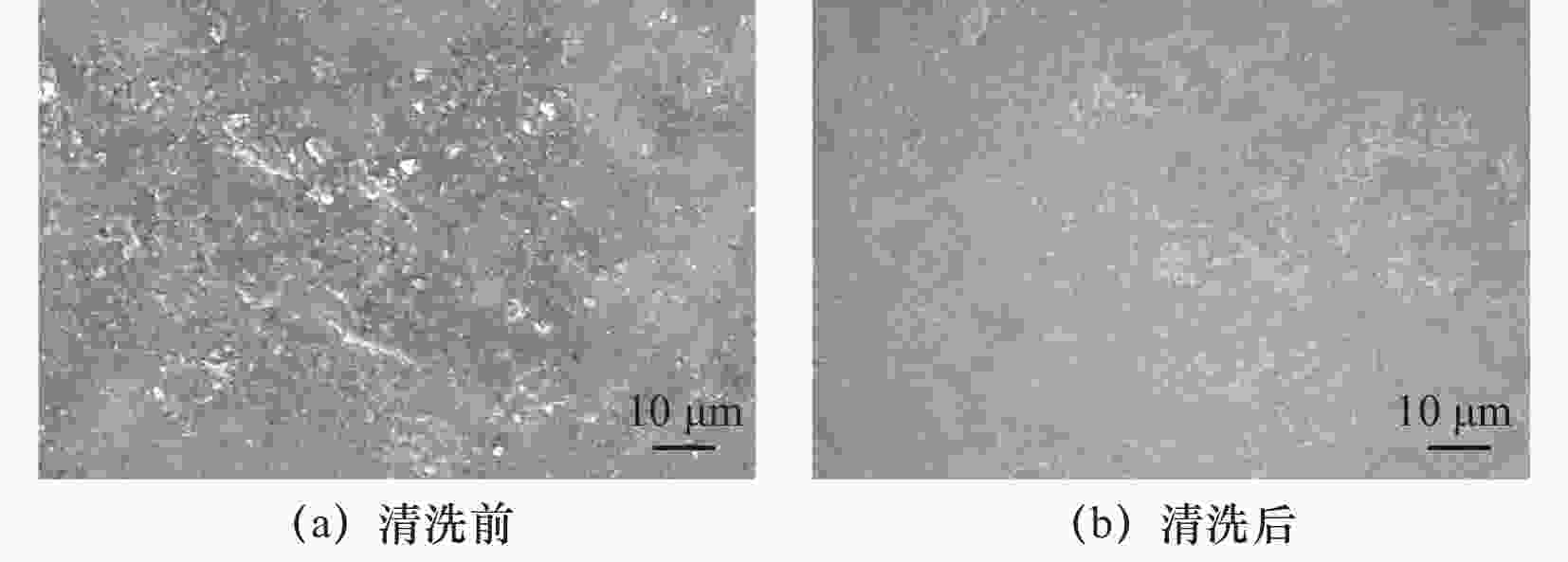

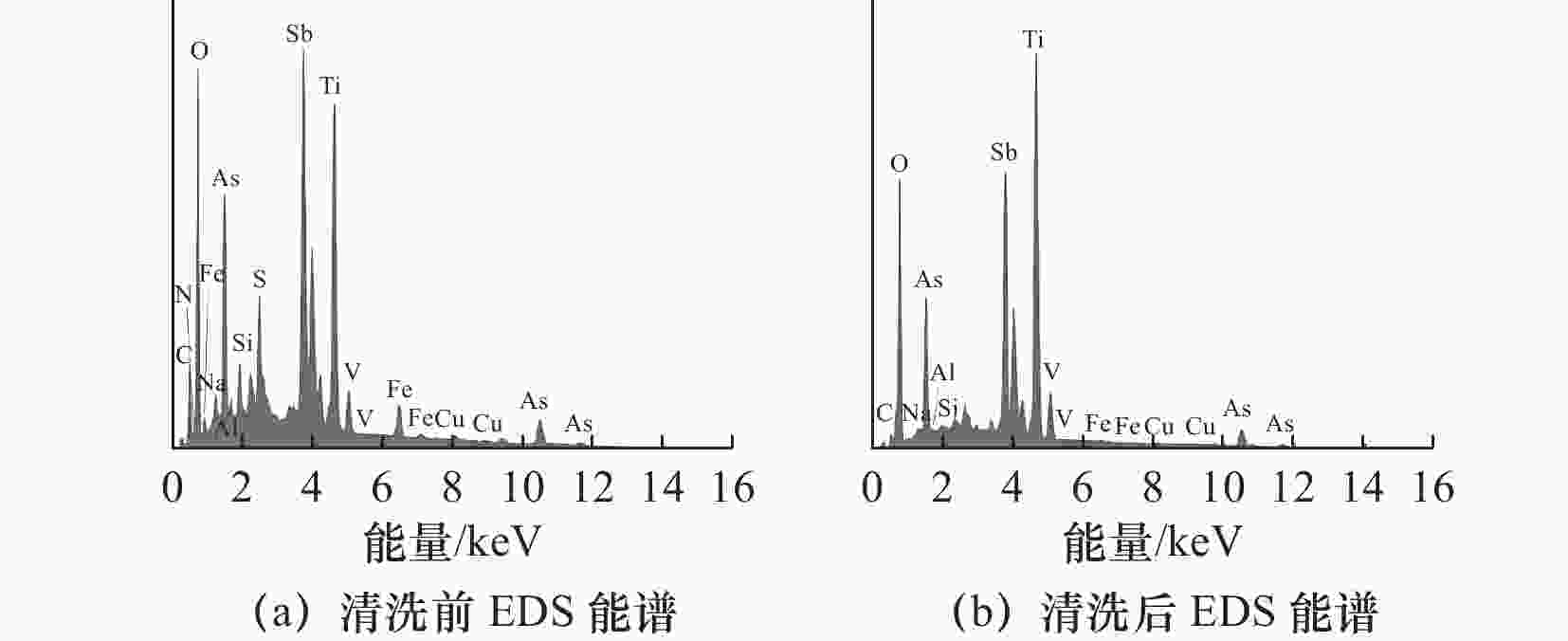

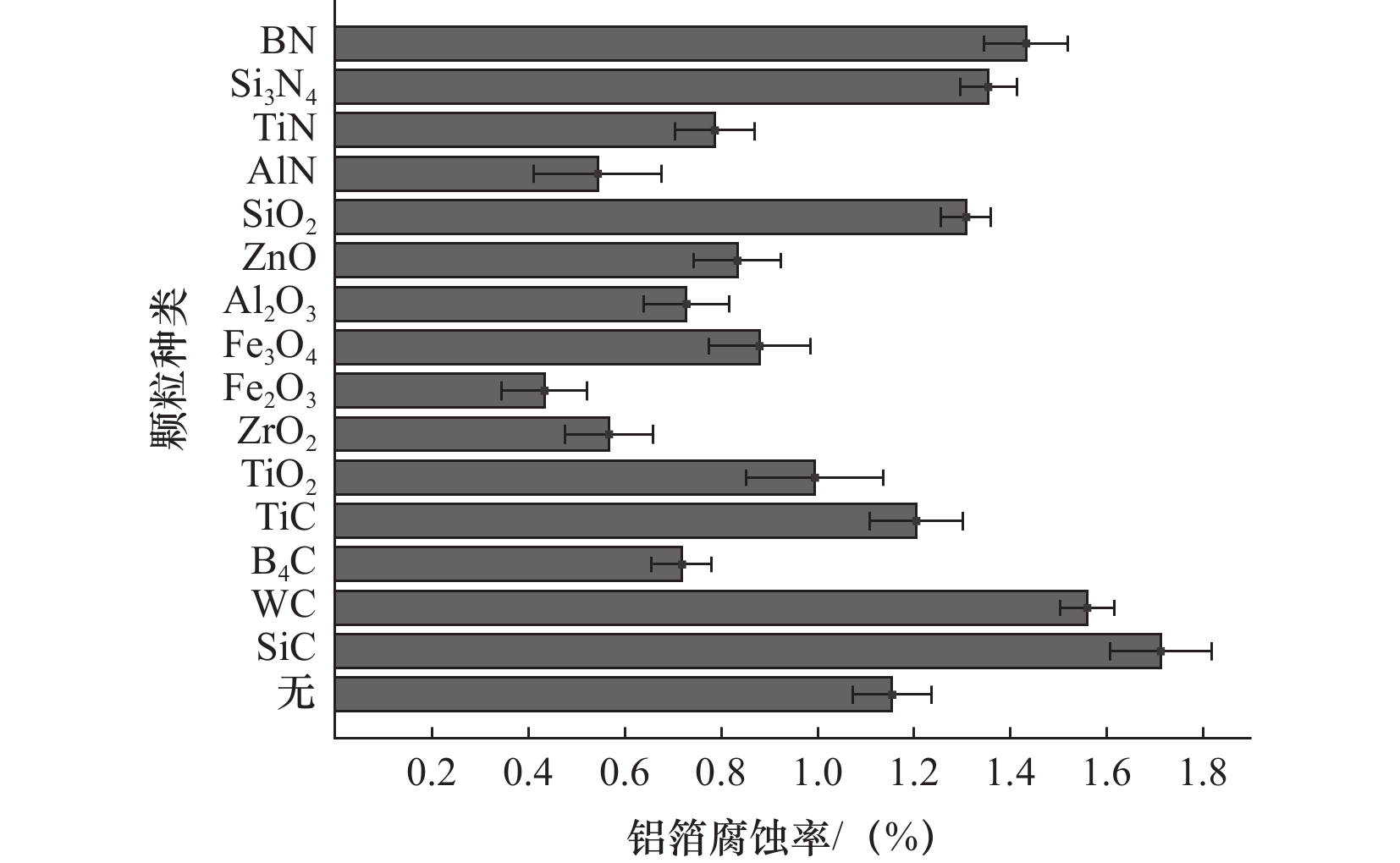

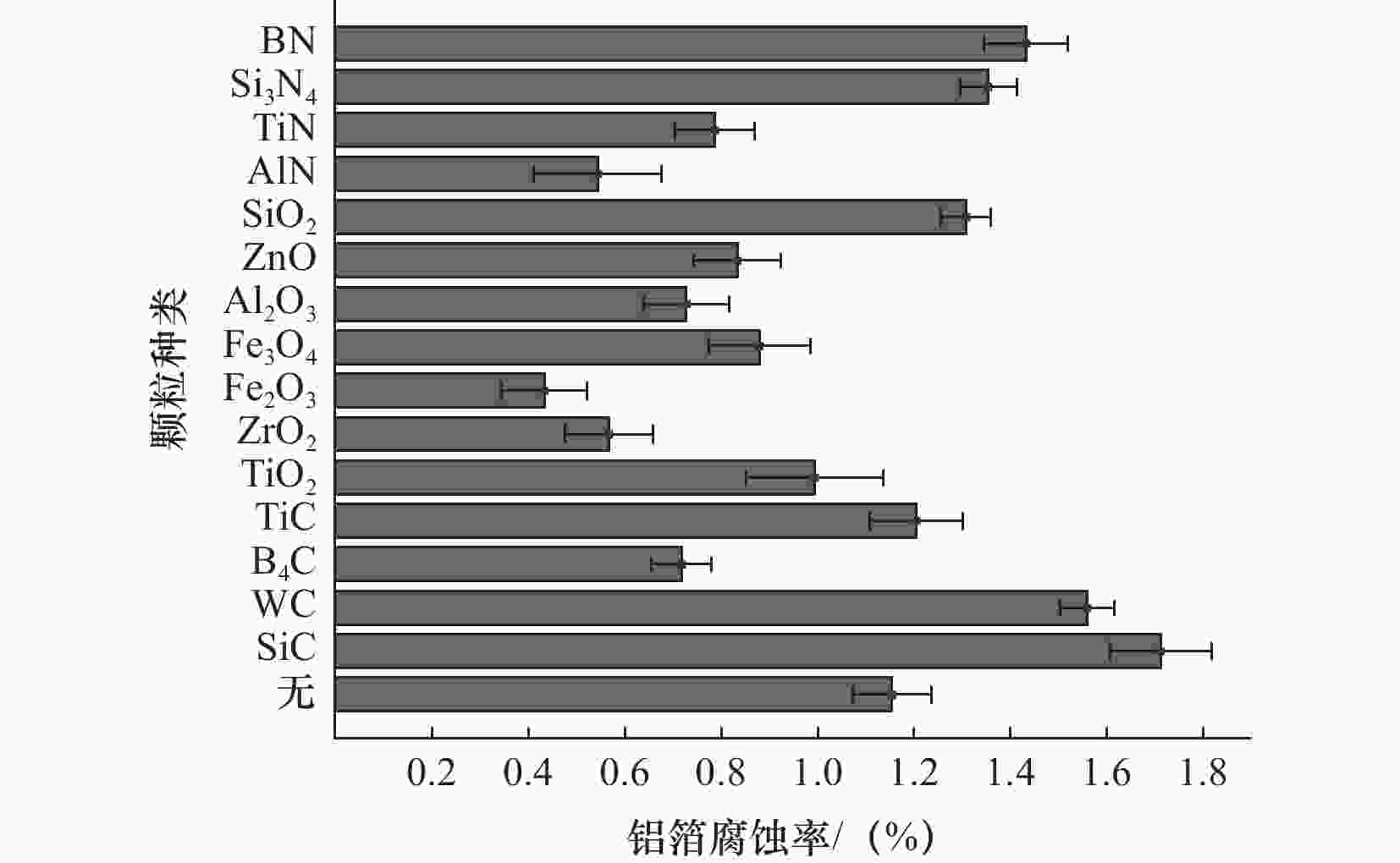

摘要: 铜电解阴极钛板作为铜电解工艺的重要组成部分,其表面质量对电解质量和效率及钛板本身使用寿命有显著影响。针对此问题,采用碳化硅悬浮液超声波协同清洗技术对钛板进行简单、高效、环保的表面处理。通过铝箔腐蚀法探究了最佳清洗参数,分析了清洗过程中的协同效应及其作用机理。通过SEM+EDS和接触角测量仪对钛板表面清洁度、微观形貌和湿润性进行表征和评价。结果表明:距离换能器78 mm、碳化硅颗粒质量分数为0.05%,粒径为70 nm、pH值为中性、温度为55 ℃时清洗效果最佳;碳化硅悬浮液作为清洗介质,其协同效应可以明显提高清洗效率,改善钛板表面质量;清洗前后的对比表明,协同清洗能够有效地去除钛板表面的污染物,提高表面洁净度和湿润性,恢复钛板表面微观形貌及金属光泽。研究为优化钛板清洗工艺提供参考依据。Abstract: The copper electroplating cathode titanium plate, being an essential constituent of the copper electroplating process, and its surface quality significantly impacts the electrolytic efficiency, quality, and lifespan of the titanium plates themselves. In response to this question, a simple, efficient, and environmentally friendly surface treatment for the titanium plate is employed, utilizing ultrasonic synergistic cleaning technology with a silicon carbide suspension. The optimal cleaning parameters were investigated through an aluminum foil corrosion method, and an analysis of the synergistic effects during the cleaning process and their underlying mechanisms was conducted. Surface cleanliness, micro-morphology and wettability of titanium plates were characterized and evaluated by SEM+EDS and contact angle measurement. The results showed that the best cleaning effect was achieved at a distance of 78 mm from the transducer, a silicon carbide particle mass fraction of 0.05%, a particle size of 70 nm, a neutral pH, and a temperature of 55°C. The synergistic effect of silicon carbide suspension as a cleaning medium can significantly increase the cleaning efficiency and improve the surface quality of titanium plates. Comparison before and after cleaning shows that synergistic cleaning can effectively remove the contaminants on the surface of titanium plate, improve the surface cleanliness and wettability, and restore the surface micro-morphology and metallic luster of titanium plate. The study provides a reference basis for optimizing the cleaning process of titanium plate.

-

表 1 钛板表面元素组成及占比

元素 清洗前 清洗后 质量百分比/

(%)原子数量百分比/

(%)质量百分比/

(%)原子数量百分比/

(%)C 13.29 29.67 2.84 7.25 N 1.48 2.83 — — O 27.06 45.36 33.82 64.93 Na 0.90 1.05 0.38 0.51 Al 0.33 0.32 0.04 0.04 Si 1.00 0.96 0.14 0.15 S 1.54 1.29 — — Ti 13.17 7.37 24.73 15.86 V 0.05 0.03 0.06 0.04 Fe 1.98 0.95 0.12 0.07 Cu 0.44 0.19 0.16 0.08 As 10.44 3.74 9.97 4.08 Sb 28.32 6.24 27.74 7.00 -

[1] 华宏全,黄太祥,徐瑞东,等. 浅谈不锈钢阴极在云铜的生产试验及应用[J]. 中国有色冶金,2007(5):45-48. doi: 10.3969/j.issn.1672-6103.2007.05.011 [2] 殷胜民. 电解锰阴极板超声波清洗机的研制[D]. 湘潭:湘潭大学,2012. [3] Kravchenko I N,Amelin S S,Kurmenev D V,et al. Formation of the working flux in an abrasive jet for steam cleaning[J]. Russian Engineering Research,2022,42(7):685-688. doi: 10.3103/S1068798X22070176 [4] Varshney P,Mohapatra S S. Durable and regenerable superhydrophobic coatings for brass surfaces with excellent self-cleaning and anti-fogging properties prepared by immersion technique[J]. Tribology International,2018,123(1):17-25. [5] GB/T 39293–2000《工业清洗术语和分类》[J]. 中国洗涤用品工业,2021(3):70-77. [6] Mat-Shayuti M,Tuan Ya T M Y S ,Abdullah M Z,et al. Progress in ultrasonic oil-contaminated sand cleaning:a fundamental review[J]. Environmental Science and Pollution Research International,2019,26(26):26419-26438. [7] 王振华. 超声波清洗技术[M]. 武汉:武汉理工大学出版社,2019. [8] 李璐,李家成,王佳豪,等. 超声波清洗技术在工业领域的应用研究进展[J]. 应用化工,2021,50(3):759-764. doi: 10.3969/j.issn.1671-3206.2021.03.041 [9] 黄志超,涂林鹏,刘举平,等. 超声波清洗技术及设备研究进展[J]. 华东交通大学学报,2020,37(3):1-9. [10] Sarasua Miranda J A,Ruiz-Rubio L,Aranzabe Basterrechea E,et al. Non-immersion ultrasonic cleaning:An efficient green process for large surfaces with low water consumption[J]. Processes,2021,9(4):585. doi: 10.3390/pr9040585 [11] 崔玉洪. 基于超声波清洗技术的喷涂清洗装置集成设计及应用实践[J]. 制造技术与机床,2019(12):82-84. [12] Ando K,Sugawara M,Sakota R. Particle removal in ultrasonic water flow cleaning role of cavitation bubbles as cleaning agents[J]. Solid State Phenomena,2021,314:218-221. doi: 10.4028/www.scientific.net/SSP.314.218 [13] Peng C,Zhang C Y ,Li Q F,et al. Erosion characteristics and failure mechanism of reservoir rocks under the synergistic effect of ultrasonic cavitation and micro-abrasives[J]. Advanced Powder Technology,2021,32(11):4391-4407. [14] Su K P ,Wu J H ,Xia D K. Classification of regimes determining ultrasonic cavitation erosion in solid particle suspensions[J]. Ultrasonics Sonochemistry,2020,68:105214. [15] LI S C. Cavitation enhancement of silt erosion—An envisaged micro model[J]. Wear,2005,260(9):1145-1150. [16] Su K P,Xia D K,Wu J H,et al. Particle size distribution effects on cavitation erosion in sediment suspensions[J]. Wear,2023:518-519. [17] Yuan B J,Jiang Y Z,Zhu L . Study on the processing methods of aluminum foil measurement signals for ultrasonic cleaning parameters[C]. Second International Conference on Digital Manufacturing & Automation,2011:1180-1183. [18] Fuchs F J. 19-Ultrasonic cleaning and washing of surfaces[J]. Power Ultrasonics,2015:577-609. [19] Chakraborty D,Chakraborty S. Microfluidic transport and micro-scale flow physics:An overview[J]. Microfluidics and Microfabrication,2010:1-85. [20] Mason T J. Ultrasonic cleaning:An historical perspective[J]. Ultrasonics - Sonochemistry,2016,29:519-523. doi: 10.1016/j.ultsonch.2015.05.004 [21] Aktij S A ,Taghipour A,Rahimpour A,et al. A critical review on ultrasonic-assisted fouling control and cleaning of fouled membranes[J]. Ultrasonics,2020,108:106228. [22] Fu Y Z,Zhu X J,Wang J Q,et al. Numerical study of the synergistic effect of cavitation and micro-abrasive particles[J]. Ultrasonics Sonochemistry,2022,89:106119. doi: 10.1016/j.ultsonch.2022.106119 [23] Romero R,Teran L A,Coronado J J,et al. Synergy between cavitation and solid particle erosion in an ultrasonic tribometer[J]. Wear,2019:428-429. [24] Luo J,Xu W L,Zhai Y W,et al. Experimental study on the mesoscale causes of the influence of viscosity on material erosion in a cavitation field[J]. Ultrasonics Sonochemistry,2019,59(C):104699. [25] Sakr M,Mohamed M M,Maraqa M A,et al. A critical review of the recent developments in micro–nano bubbles applications for domestic and industrial wastewater treatment[J]. Alexandria Engineering Journal,2022,61(8):6591-6612. doi: 10.1016/j.aej.2021.11.041 [26] Matin A ,Laoui T ,Falath W ,et al. Fouling control in reverse osmosis for water desalination & reuse:Current practices & emerging environment-friendly technologies[J]. The Science of the Total Environment,2021,765(15):142721. [27] Radziuk D,Möhwald H. Ultrasonically treated liquid interfaces for progress in cleaning and separation processes[J]. Physical Chemistry Chemical Physics,2016,18:21-46. [28] Bakthavatchalam B,Habib K,Saidur R,et al. Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement:A review on current and future perspective[J]. Journal of Molecular Liquids,2020,305:112787. doi: 10.1016/j.molliq.2020.112787 [29] Sarasua J A,Rubio L R,Aranzabe E,et al. Energetic study of ultrasonic wettability enhancement[J]. Ultrasonics Sonochemistry,2021,79:105768. doi: 10.1016/j.ultsonch.2021.105768 [30] Li M D,Bussonnière A,Xiang B L,et al. Effect of solid wettability on three-phase hydrodynamic cavitation[J]. Minerals Engineering,2022,180:107455. doi: 10.1016/j.mineng.2022.107455 -

下载:

下载: