| [1] |

Terziyan V,Gryshko S,Golovianko M. Patented intelligence:Cloning human decision models for Industry 4.0[J]. Journal of Manufacturing Systems,2018,48:204-217. doi: 10.1016/j.jmsy.2018.04.019

|

| [2] |

Huang Z,Kim J,Sadri A,et al. Industry 4.0:Development of a multi-agent system for dynamic value stream mapping in SMEs[J]. Journal of Manufacturing Systems,2019,52:1-12. doi: 10.1016/j.jmsy.2019.05.001

|

| [3] |

Mittal S,Khan M A,Romero D,et al. A critical review of smart manufacturing & Industry 4.0 maturity models:Implications for small and medium-sized enterprises (SMEs)[J]. Journal of Manufacturing Systems,2018,49:194-214. doi: 10.1016/j.jmsy.2018.10.005

|

| [4] |

Sahal R,Breslin J G,Ali M I. Big data and stream processing platforms for Industry 4.0 requirements mapping for a predictive maintenance use case[J]. Journal of Manufacturing Systems,2020,54:138-51. doi: 10.1016/j.jmsy.2019.11.004

|

| [5] |

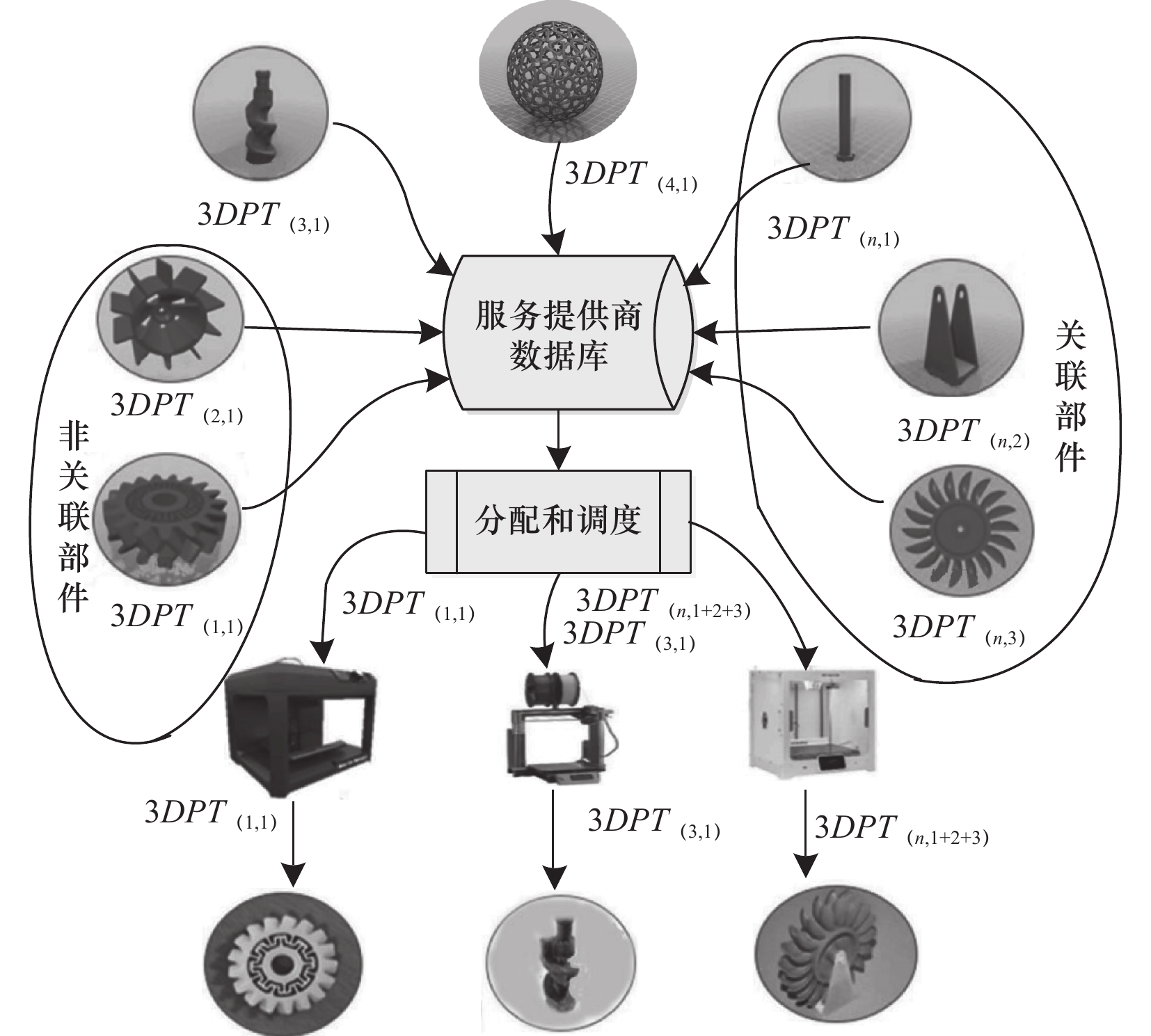

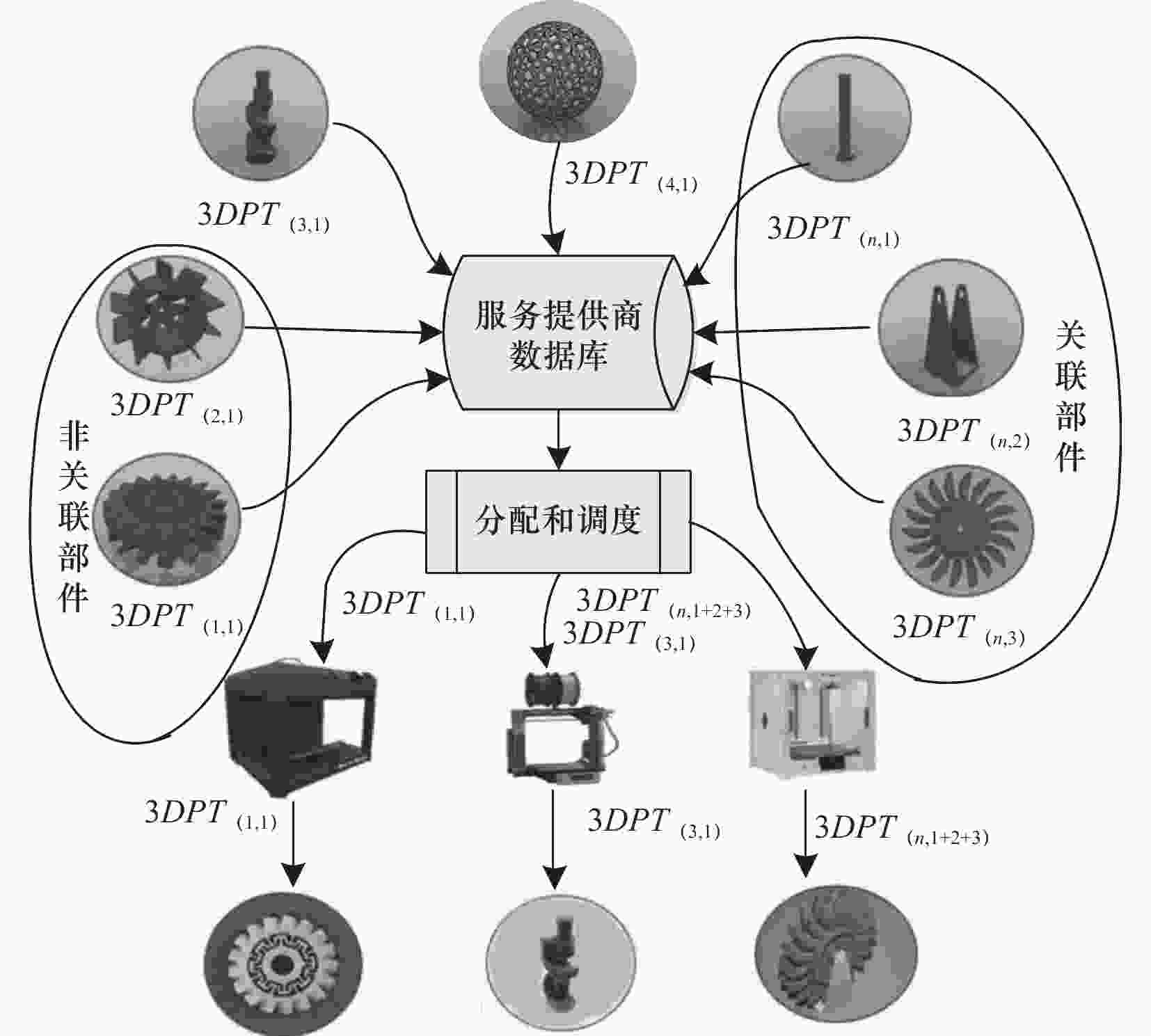

Chen T C T,Lin Y C. A three-dimensional-printing-based agile and ubiquitous additive manufacturing system[J]. Robotics and Computer-Integrated Manufacturing,2019,55:88-95. doi: 10.1016/j.rcim.2018.07.008

|

| [6] |

Chen T,Wang Y C. An advanced IoT system for assisting ubiquitous manufacturing with 3D printing[J]. International Journal of Advanced Manufacturing Technology,2019,103:1721-1733. doi: 10.1007/s00170-019-03691-5

|

| [7] |

Wang Y,Lin Y,Zhong R Y,et al. IoT-enabled cloud-based additive manufacturing platform to support rapid product development[J]. International Journal of Production Research,2019,57:3975-3991. doi: 10.1080/00207543.2018.1516905

|

| [8] |

赵军富,李建军,王猛. 基于物联网实时监控生产车间的能源效率研究[J]. 制造技术与机床,2021(4):20-23.

|

| [9] |

Ngo T D,Kashani A,Imbalzano G,et al. Additive manufacturing (3D printing):A review of materials,methods,applications and challenges[J]. Composites Part B-Engineering,2018,143:172-96. doi: 10.1016/j.compositesb.2018.02.012

|

| [10] |

Mai J G,Zhang L,Tao F,et al. Customized production based on distributed 3D printing services in cloud manufacturing[J]. The International Journal of Advanced Manufacturing Technology,2016,84:71-83. doi: 10.1007/s00170-015-7871-y

|

| [11] |

赵军富,李建军. 基于物联网数字工厂与智能工厂的整合研究[J]. 制造技术与机床,2020(4):20-25.

|

| [12] |

Lu B H,Li D C,Tian X Y. Development trends in additive manufacturing and 3D printing[J]. Engineering,2015,1(1):85-89. doi: 10.15302/J-ENG-2015012

|

| [13] |

Guo L,Qiu J X. Combination of cloud manufacturing and 3D printing:Research progress and prospect[J]. International Journal of Advanced Manufacturing Technology,2018,96:1929-1942. doi: 10.1007/s00170-018-1717-3

|

| [14] |

Knofius N,van der Heijden M C,Zijm W H M. Moving to additive manufacturing for spare parts supply[J]. Computers in Industry,2019,113:134.

|

| [15] |

Li B H,Zhang L,Wang S L,et al. Cloud manufacturing:A new service-oriented networked manufacturing model[J]. Computer Integrated Manufacturing System,2010,16:1-7.

|

| [16] |

Zhang L,Luo Y L,Tao F,et al. Cloud manufacturing:A new manufacturing paradigm[J]. Enterprise Modelling and Information Systems Architectures,2014,8(2):167-187. doi: 10.1080/17517575.2012.683812

|

| [17] |

Wang S L,Guo L,Kang L,et al. Research on selection strategy of machining equipment in cloud manufacturing[J]. International Journal of Advanced Manufacturing Technology,2014,71:1549-1563. doi: 10.1007/s00170-013-5578-5

|

| [18] |

Liu Y K,Xu X,Zhang L,et al. Workload-based multi-task scheduling in cloud manufacturing[J]. Robot and Computer Integrated Manufacturint,2017,45:3-20. doi: 10.1016/j.rcim.2016.09.008

|

| [19] |

Wang L,Guo S S,Li X X,et al. Distributed manufacturing resource selection strategy in cloud manufacturing[J]. International Journal of Advanced Manufacturing Technology,2018,94:3375-3388. doi: 10.1007/s00170-016-9866-8

|

| [20] |

Cheng Y,Tao F,Liu Y,et al. Energy-aware resource service scheduling based on utility evaluation in cloud manufacturing system[J]. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture Manufacture,2013,227:1901-1915. doi: 10.1177/0954405413492966

|

| [21] |

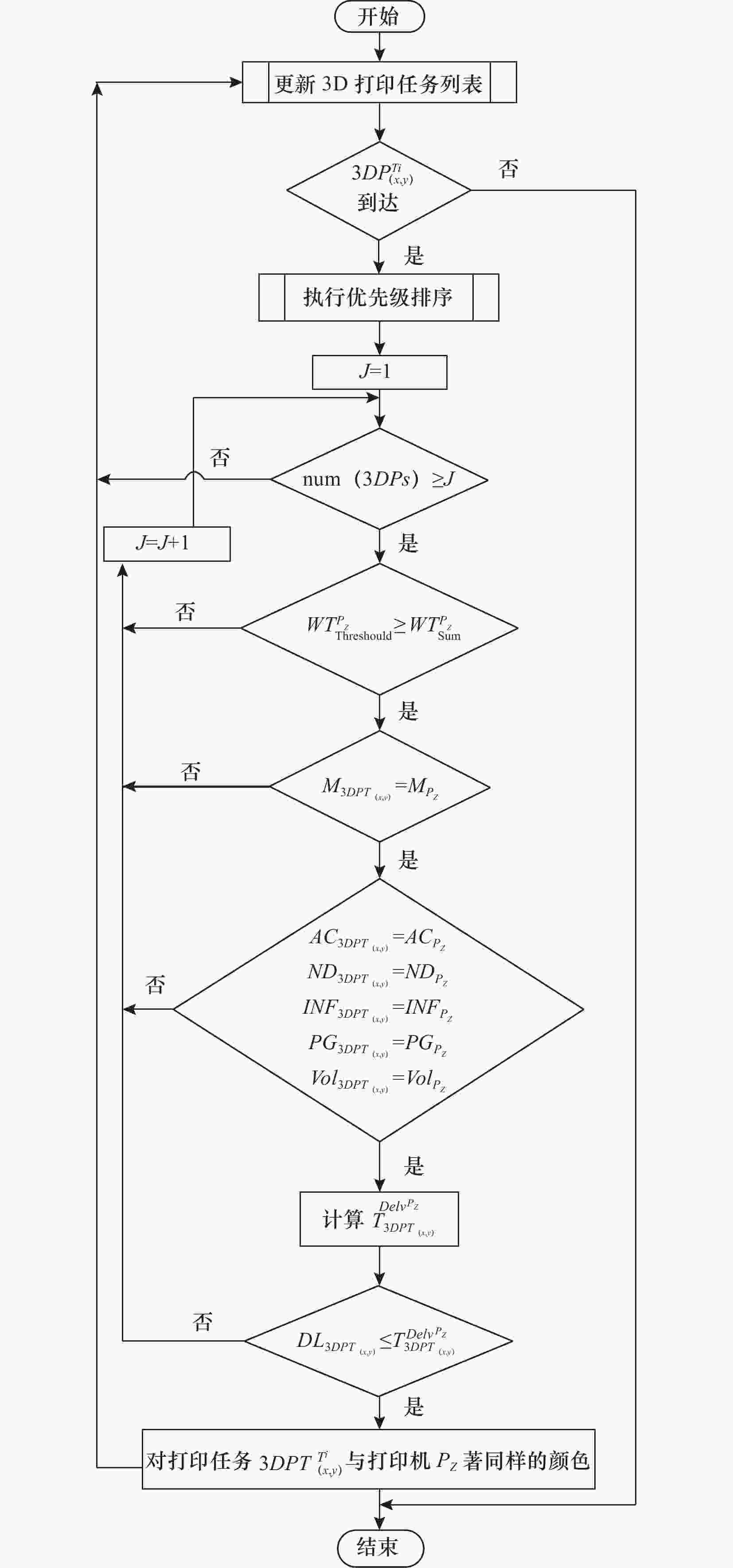

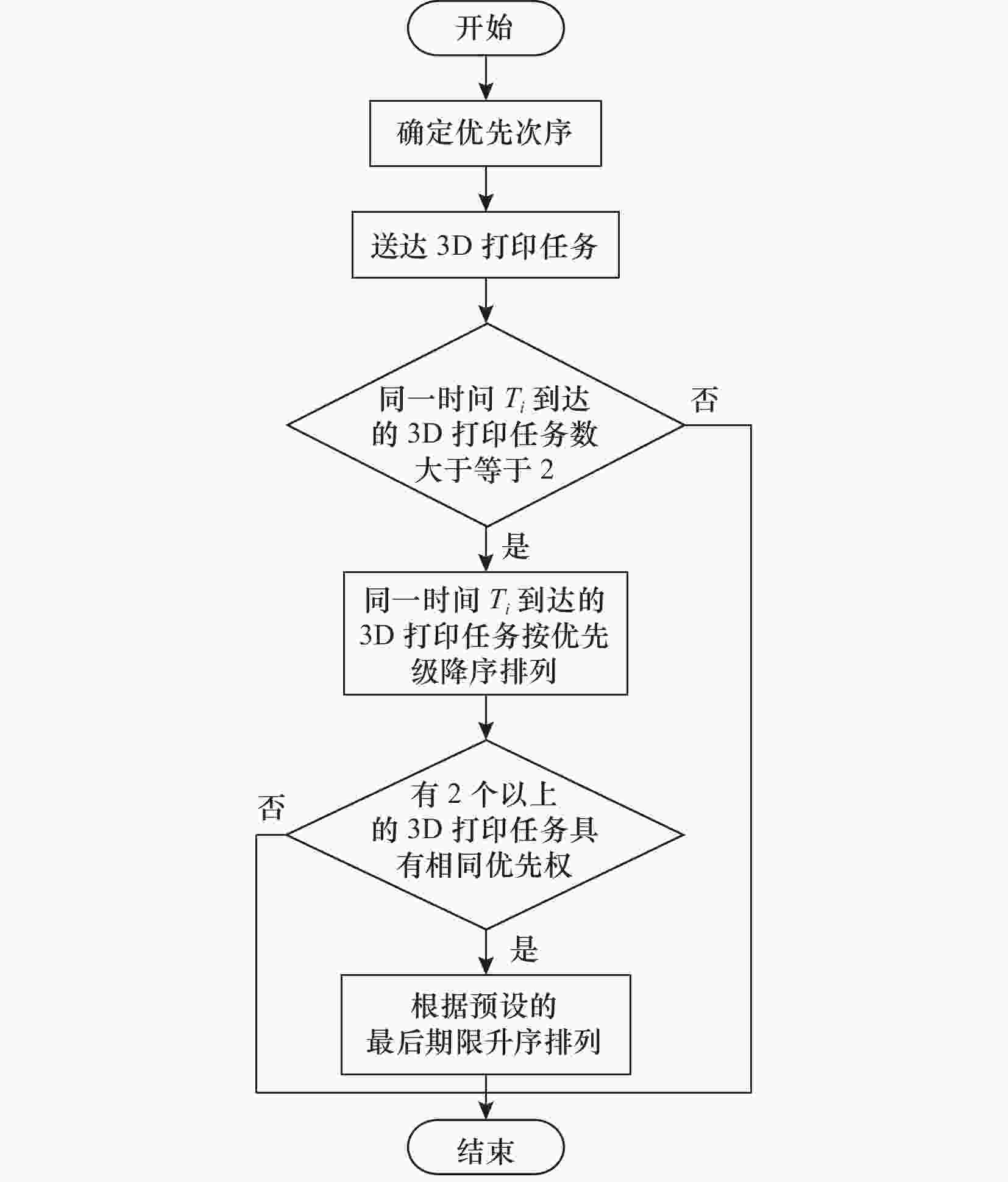

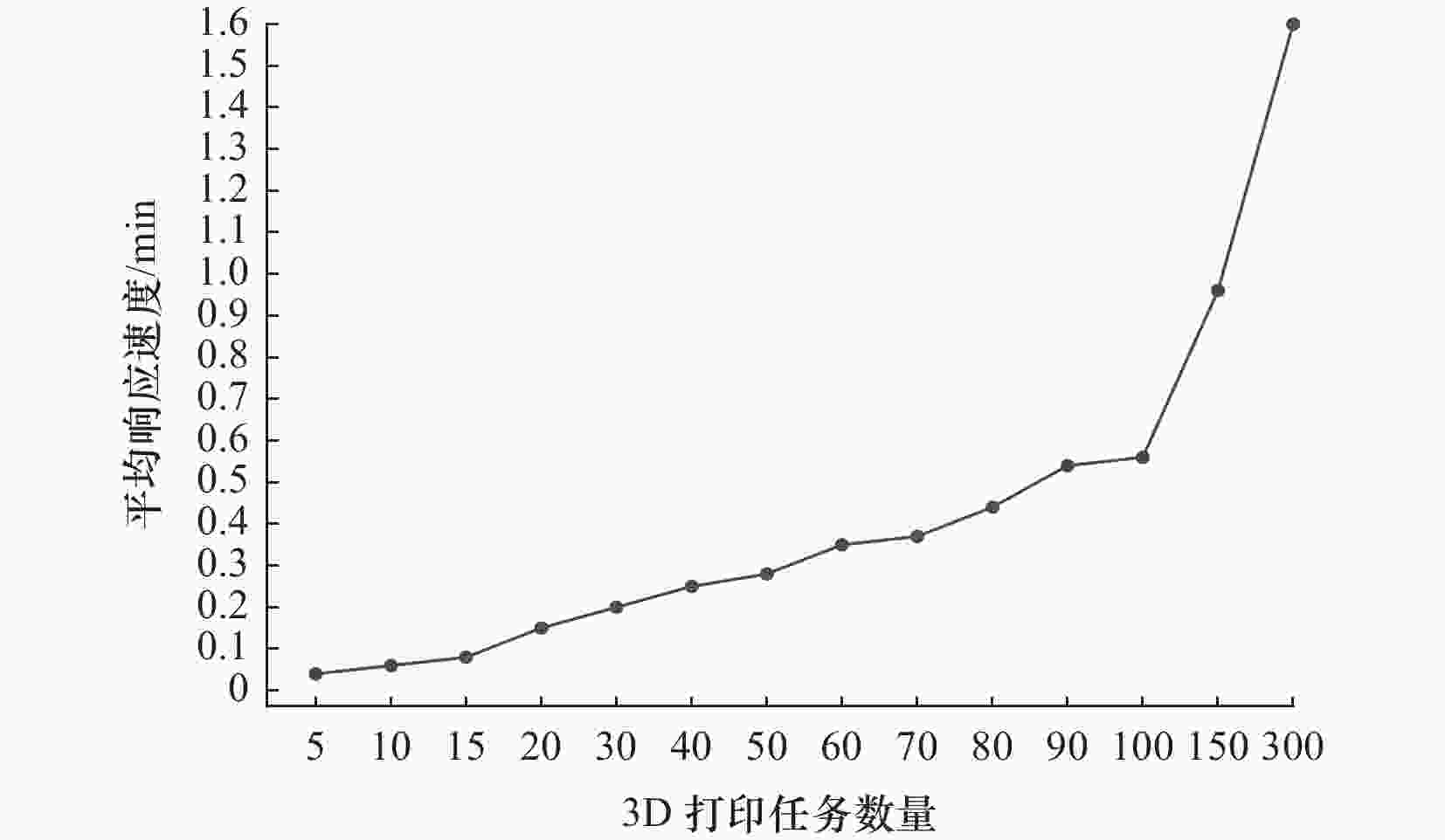

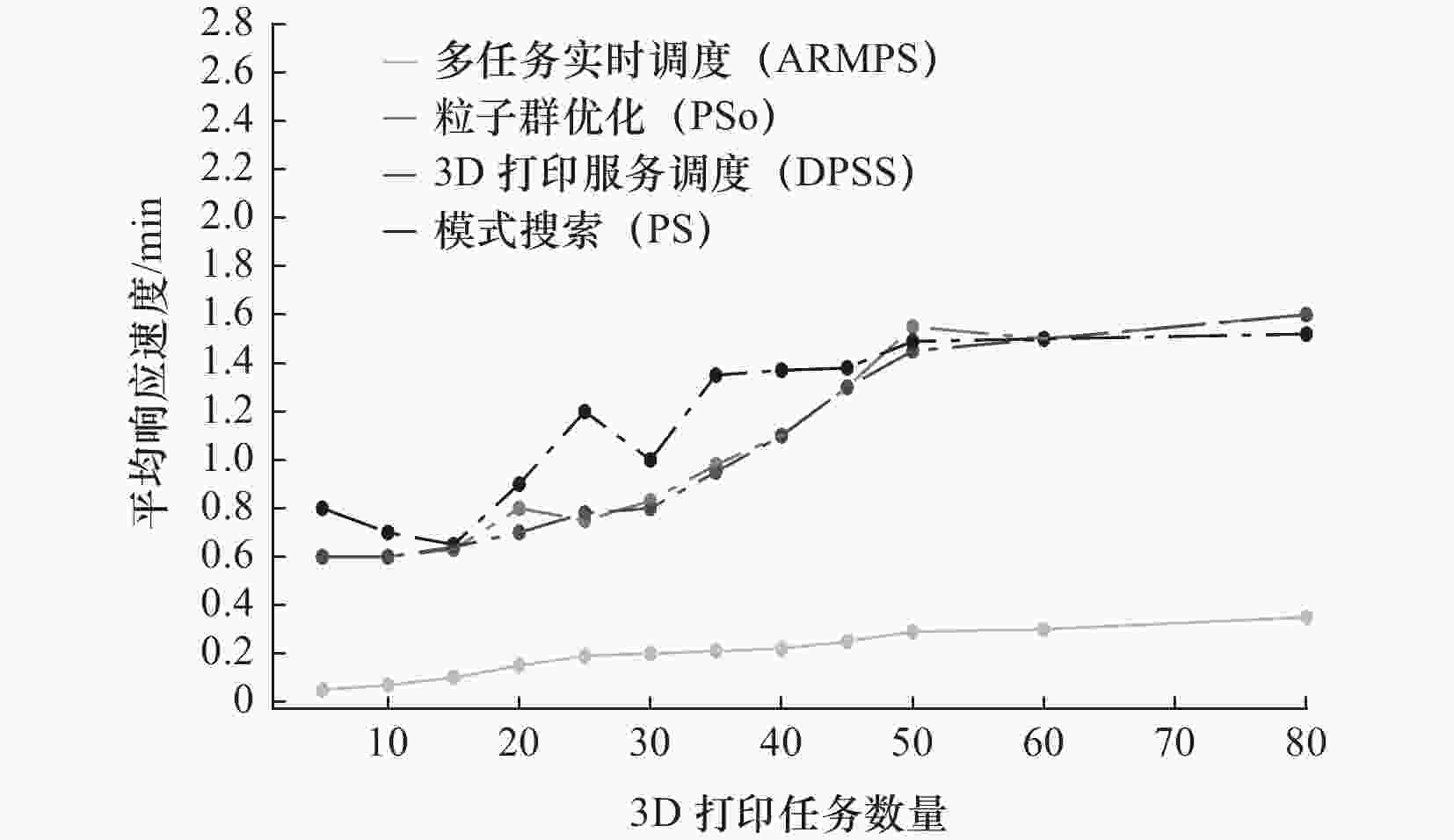

Zhou L F,Zhang L,Laili Y J,et al. Multi-task scheduling of distributed 3D printing services in cloud manufacturing[J]. International Journal of Advanced Manufacturing Technology,2018,96:3003-3017. doi: 10.1007/s00170-017-1543-z

|

| [22] |

Luo X,Zhang L,Ren L,et al. A dynamic and static data based matching method for cloud 3D printing[J]. Robot and Computer-Integrated Manufacturing,2020,61:101858.

|

| [23] |

Halldorsson M M. Parallel and on-line graph coloring algorithms. Lect notes computsci (Including subser lect notes artif intell lect notes bioinformatics)[J]. International Symposium on Algorithms and Computation,1992,650:61-70.

|

下载:

下载: