Comparison of attitude capability of 3-PRS parallel mechanism with different chain arrangement

-

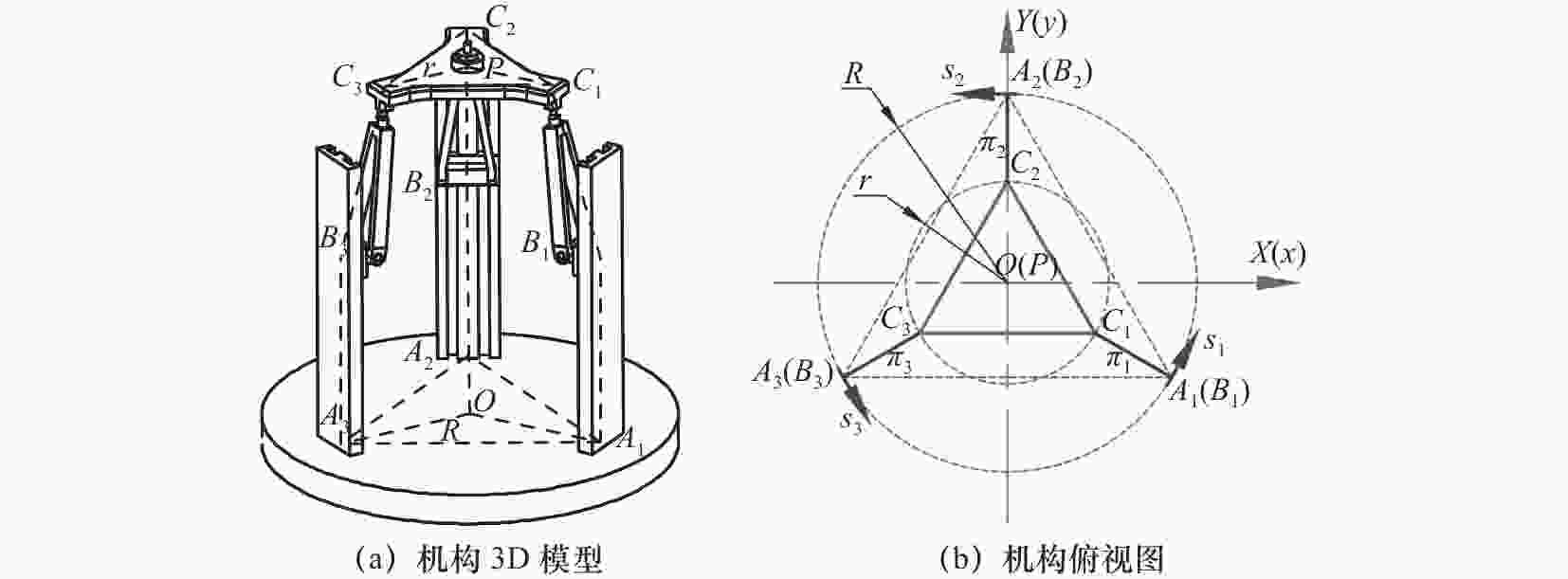

摘要: 以两种2R1T并联机构(文中称为机构A(Z3)、B)为研究对象,分析支链布局对机构姿态能力的影响。基于螺旋理论,运用运动/力传递指标求解两机构局部传递指标ITI、OTI及全局GTI。在此基础上,用数值方法,建立两机构定截面的优质传递姿态工作空间(good transmission orientational workspace, GTOW)模型。首先用经验尺寸绘制出两者边界姿态性能曲线,比较两者姿态能力,得出机构B姿态能力略好。然后,以许用传递指标[ηLTI]=0.7时的性能边界曲线的最大内切圆半径κGTOC最大化为优化目标,全局许用传递指标GTI和机构结构参数协调为约束条件,运用DE优化算法得到最优尺寸参数。以最优尺度参数绘制边界姿态性能曲线,优化后,机构A、B的姿态能力均有提高且机构B姿态能力比机构A姿态能力优良。由两机构优化姿态实力实例可得,变异Z3机构(机构B)姿态能力比Z3(机构A)优良,由此,也说明姿态能力会受支链排布的影响。Abstract: Two kinds of 2R1T parallel mechanisms (referred to as mechanisms A (Z3), B) are taken as research objects to analyze the influence of branch chain layout on the attitude capability of the mechanism. Based on the screw theory, the motion/force transfer indexes are used to solve ITI, OTI and GTI of the PMs. A numerical method is used to establish a good transmission orientational workspace (GTOW) model when given Z-direction value of the PMs. Firstly, the boundary orientational performance curves of the PMs are drawn with the empirical dimensions, and the orientational abilities of the PMs are compared. From the above conclusions, the orientation of the PM B is slightly better. Then, the maximum inscribed circle radius (referred to as κGTOC) of the performance boundary curve when the allowable transfer index [ηLTI] equals 0.7 is maximized as the optimization objective, the GTI and the PM’s structure parameter are coordinated as constraints, and the DE is used to obtain the optimal dimensional parameters of PMs. Finally, the boundary orientational performance curve is drawn with the optimal dimensional parameters. After optimized, the orientation of the PMs are increased by 2.65° and 2.04° respectively. According to the example of optimizing the orientational ability of the PMs, the orientational ability of the PM B is reduced by 0.15 compared with PM A, which indicates that the orientational abilities of the PMs are not much different, but the orientational ability is affected by the branch arrangement.

-

Key words:

- 3-PRS parallel mechanism /

- GTOW /

- maximum inscribed circle radius /

- DE algorithm

-

表 1 机构κGTOC比较

尺寸参数 机构A 机构B 经验尺寸 优化尺寸 经验尺寸 优化尺寸 r /mm 50 79 50 78 l /mm 300 592 300 595 GTOC/(°) 33.48 40.83 34.11 41.14 GTI 0.870 0.882 0.867 0.882 -

[1] Zlatanov D, Bonev I A, Gosselin C M. Constraint singularities of parallel mechanisms[C]. 2002 IEEE International Conference on Robotics and Automation (ICRA 2002), 2002, 1: 496-502. [2] Joachim W. Articulated tool head: US, US6431802 B1[P]. 2001. [3] Ni Y B, Zhang B, Sun Y, et al. Accuracy analysis and design of A3 parallel spindle head[J]. Chinese Journal of Mechanical Engineering, 2016, 29(2): 239-249. doi: 10.3901/CJME.2015.1210.144 [4] Siciliano B. The Tricept robot: Inverse kinematics, manipulability analysis and closed-loop direct kinematics algorithm[J]. Robotica, 1999, 17(4): 437-445. doi: 10.1017/S0263574799001678 [5] 杨应洪, 尹显明. 一种2RPS-RPU并联机构的动力学分析[J]. 机械设计与制造, 2019(9): 58-62,66. doi: 10.3969/j.issn.1001-3997.2019.09.015 [6] 吕叶萍, 许勇, 刘勇, 等. 一种含闭环结构单元的新型2R1T并联机构运动性能优化[J]. 机械设计与研究, 2019, 35(2): 50-54,59. [7] Wang J S, Wu C, Liu X J. Performance evaluation of parallel manipulators: Motion / force transmissibility and its index[J]. Mechanism and Machine Theory, 2010, 45(10): 1462-1476. doi: 10.1016/j.mechmachtheory.2010.05.001 [8] 车林仙, 陈国旺, 杜力, 等. 传递空间最大化的球面5R并联机构尺度优化[J]. 机械传动, 2020, 44(6): 37-43. [9] Wang F B, Chen Q H, Li Q C. Optimal design of a 2-upr-rpu parallel manipulator[J]. Journal of Mechanical Design, 2015, 137(5):054501. [10] Assal S. A novel planar parallel manipulator with high orientation capability for a hybrid machine tool: kinematics, dimensional synthesis and performance evaluation[J]. Robotica, 2017, 35(5): 1031-1053. doi: 10.1017/S0263574715000958 [11] Pond G, Carretero J A. Architecture optimisation of three 3-PRS variants for parallel kinematic machining[J]. Robotics and Computer-Integrated Manufacturing, 2009, 25(1): 64-72. doi: 10.1016/j.rcim.2007.09.002 [12] Sun T, Song Y M, Li Y G, et al. Dimensional synthesis of a 3-DOF parallel manipulator based on dimensionally homogeneous Jacobian matrix[J]. SCI China Ser E, 2010, 53(1): 168-174. doi: 10.1007/s11431-009-0375-y [13] Gao Z, Zhang D, Ge Y. Design optimization of a spatial six degree-of-freedom parallel manipulator based on artificial intelligence approaches[J]. Robotics and Computer-Integrated Manufacturing, 2010, 26(2): 180-189. doi: 10.1016/j.rcim.2009.07.002 [14] Liu X J, Jin Z L, Gao F. Optimum design of 3-DOF spherical parallel manipulators with respect to the conditioning and stiffness indices[J]. Mechanism and Machine Theory, 2000, 35(9): 1257-1267. doi: 10.1016/S0094-114X(99)00072-5 [15] Belkacem B. Multi-objective optimal design based kineto-elastostatic performance for the delta parallel mechanism[J]. Robotica, 2016, 34(2): 258-273. doi: 10.1017/S0263574714001416 [16] He K, Yang Z J, Yun B, et al. Intelligent fault diagnosis of delta 3d printers using attitude sensors based on support vector machines[J]. Sensors, 2018, 18(4): 1298. doi: 10.3390/s18041298 [17] Huang G Y, Guo S, Zhang D, et al. Kinematic analysis and multi-objective optimization of a new reconfigurable parallel mechanism with high stiffness[J]. Robotica, 2018, 36(2): 187-203. doi: 10.1017/S0263574717000236 [18] 侯雨雷, 汪毅, 范建凯, 等. 3-PCSS/S球面并联肩关节机构优化与仿生设计[J]. 机械工程学报, 2015, 51(11): 16-23. [19] Wang L P, Xu H Y, Li W G. Optimal design of a 3-PUU parallel mechanism with 2R1T DOFs[J]. Mechanism and Machine Theory, 2017, 114: 190-203. doi: 10.1016/j.mechmachtheory.2017.03.008 [20] Chen X, Liu X J, Xie F G, et al. A comparison study on motion/force transmissibility of two typical 3-DOF parallel manipulators: The sprint Z3 and A3 tool heads[J]. International Journal of Advanced Robotic Systems, 2014, 11(1): 1-10. doi: 10.5772/56810 [21] Li Q C, Chen Z, Chen Q H, et al. Parasitic motion comparison of 3-PRS parallel mechanism with different limb arrangements[J]. Robotics and Computer Integrated Manufacturing, 2011, 27(2): 389-396. doi: 10.1016/j.rcim.2010.08.007 [22] 王大志, 何凯, 杜如虚. 基于约束图谱旋量分析方法的调平机构约束设计[J]. 机械工程学报, 2011, 47(19): 49-58. [23] Dai J S, Jones J R. Null-space construction using cofactors from a screw-algebra context[J]. Proceedings of the Royal Society. Mathematical, Physical and Engineering Sciences, 2002, 458(2024): 1845-1866. doi: 10.1098/rspa.2001.0949 [24] Wu C, Liu X J, Wang L P, et al. Optimal design of spherical 5R parallel manipulators considering the motion/force transmissibility[J]. Journal of Mechanical Design, 2010, 132(3): 031002. doi: 10.1115/1.4001129 [25] Xie F G, Liu X J, Wang J S. A 3-DOF parallel manufacturing module and its kinematic optimization[J]. Robotics and Computer- Integrated Manufacturing, 2012, 28(3): 334-343. doi: 10.1016/j.rcim.2011.10.003 [26] 文世坤, 车林仙, 杜力, 等. 三移动一转动4-PRPaU并联机构运动学分析[J]. 机械传动, 2020, 44(11): 121-126,151. [27] Deb K. An efficient constraint handling method for genetic algorithms[J]. Computer Methods in Applied Mechanics and Engineering, 2000, 186(2/4): 311-338. -

下载:

下载: